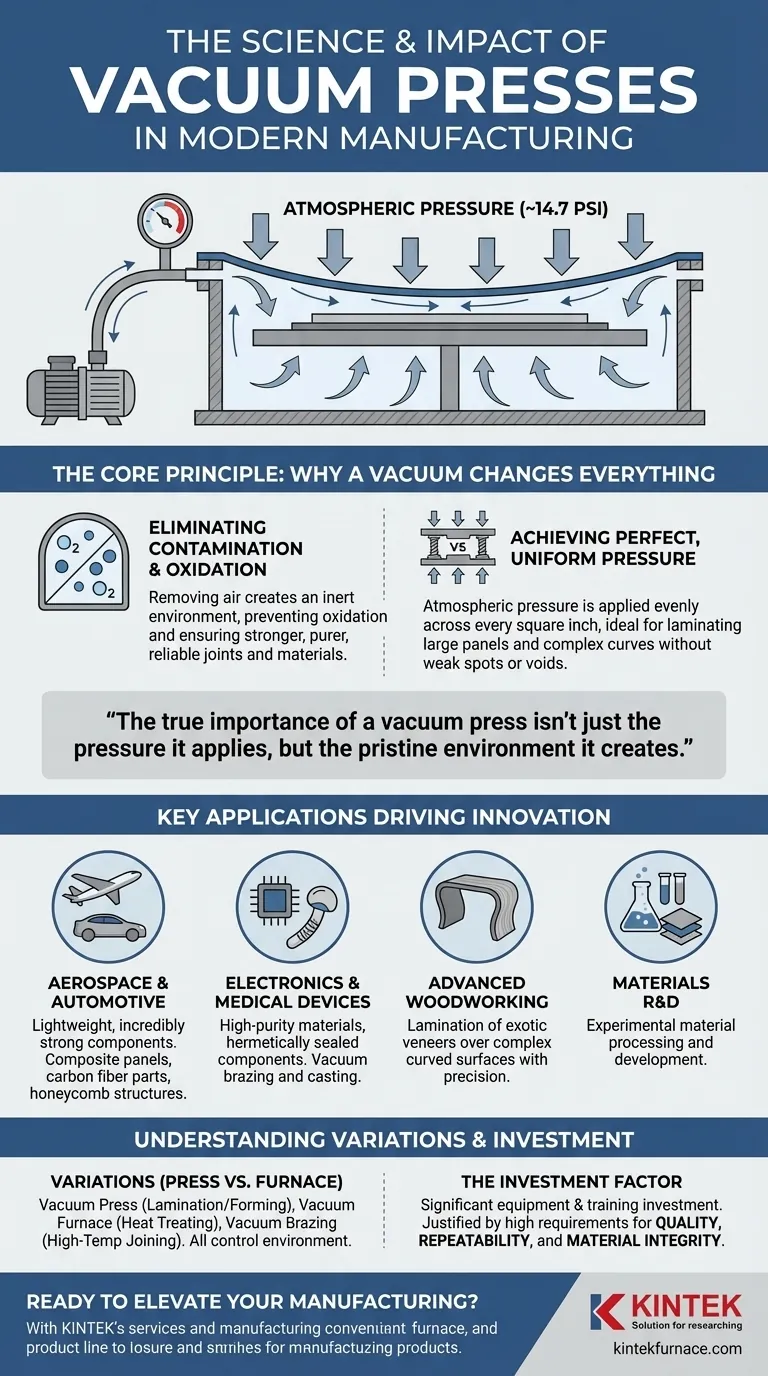

At its core, a vacuum press is a machine that uses atmospheric pressure to bond, laminate, or form materials inside a vacuum. By removing air from a chamber or a flexible bag, the press creates a low-pressure environment, allowing the full force of the outside atmosphere (approximately 14.7 pounds per square inch at sea level) to apply perfectly uniform pressure to the workpiece. This process is critical in modern manufacturing for creating flawless bonds and complex shapes that are impossible to achieve with traditional mechanical clamps.

The true importance of a vacuum press isn't just the pressure it applies, but the pristine environment it creates. By removing air, it eliminates contaminants and ensures perfectly even clamping force, resulting in materials and components with superior strength, finish, and reliability.

The Core Principle: Why a Vacuum Changes Everything

The magic of vacuum processing lies in what it removes: air. Taking air out of the equation solves two of manufacturing's biggest challenges: contamination and uneven pressure.

Eliminating Contamination and Oxidation

Air contains oxygen, moisture, and other elements that can interfere with manufacturing processes. When heated or bonding, many materials react with oxygen in a process called oxidation, which can weaken the final product.

A vacuum environment is an inert environment. By removing the air, processes like high-temperature bonding (brazing) or curing can occur without the risk of oxidation, producing stronger, purer, and more reliable joints and materials.

Achieving Perfect, Uniform Pressure

Mechanical clamps apply pressure only at the point of contact, creating uneven stress that can lead to weak spots, delamination, or voids in the final product.

A vacuum press, however, leverages the atmosphere itself as a clamp. Once air is evacuated, the surrounding atmospheric pressure pushes down on every square inch of the material's surface with equal force. This perfectly distributed pressure is ideal for laminating large panels, forming complex curves, and ensuring adhesives bond completely.

Key Applications Driving Innovation

The precision and quality offered by vacuum technology make it indispensable in high-stakes industries where material failure is not an option.

Aerospace and Automotive

In these sectors, creating components that are both lightweight and incredibly strong is paramount. Vacuum presses are used to manufacture composite panels, carbon fiber parts, and honeycomb structures, ensuring a flawless bond between layers without adding unnecessary weight.

Electronics and Medical Devices

For sensitive electronics or medical implants, material purity is critical. Vacuum furnaces and presses create the contamination-free conditions needed for processes like vacuum brazing and casting. This produces hermetically sealed, high-purity components that are safe and reliable for critical applications.

Advanced Woodworking and Design

Beyond industrial uses, vacuum presses have revolutionized high-end woodworking. They enable the lamination of exotic veneers over complex curved surfaces and the creation of custom-shaped furniture parts with a level of precision and durability that traditional clamping cannot match.

Understanding the Trade-offs and Variations

While powerful, vacuum technology is a specific tool for specific goals, and it's important to understand its context.

Press vs. Furnace vs. Brazing

The term "vacuum press" often refers to systems for lamination and forming. However, it's part of a larger family of vacuum processing technologies.

Vacuum furnaces are used for heat treating metals in a controlled atmosphere, while vacuum brazing systems are designed specifically for joining parts at high temperatures. All share the core principle of using a vacuum to control the environment, but the application is different.

The Investment Factor

Compared to mechanical clamps or screws, a vacuum press system is a significant investment in equipment, space, and training. Its use is justified when the required levels of quality, repeatability, and material integrity are high enough to warrant the cost. For simple, low-risk applications, traditional methods may be more practical.

Making the Right Choice for Your Goal

To determine if vacuum processing is the right solution, consider your primary manufacturing objective.

- If your primary focus is maximum material integrity and strength: Vacuum processing is essential for eliminating oxidation and ensuring void-free bonds in mission-critical components.

- If your primary focus is forming complex curves or laminating large surfaces: A vacuum press offers unparalleled uniform pressure, delivering a perfect finish that is unattainable with mechanical clamps.

- If your primary focus is cost-sensitive, low-volume production: Traditional clamping may be more practical, as the high precision of a vacuum system may not be necessary.

Ultimately, mastering the manufacturing environment is the key to mastering the final material.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Uses atmospheric pressure in a vacuum to apply uniform force, eliminating air and contaminants. |

| Main Benefits | Eliminates oxidation, ensures even pressure, and improves bond strength and reliability. |

| Primary Applications | Aerospace, automotive, electronics, medical devices, and advanced woodworking. |

| Key Industries | High-stakes sectors requiring lightweight, strong components and material purity. |

Ready to elevate your manufacturing with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, electronics, or another high-tech field, our vacuum technologies ensure flawless bonds and superior material integrity. Contact us today to discuss how we can optimize your processes and deliver unmatched value!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the typical operational steps when using a vacuum press? Master Flawless Bonding and Forming

- What is a vacuum press and what are its primary uses? Unlock High-Performance Material Processing

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- How does automation enhance the hot pressing process? Boost Precision, Efficiency, and Quality