Proper preparation of a water circulating vacuum pump is a straightforward process focused on ensuring the water, its working fluid, is clean and at the correct level. Before any operation, you must place the pump on a stable surface, fill its tank with clean, cool water up to the designated overflow nozzle, connect the vacuum line to your equipment, and then connect the unit to a suitable power supply.

A water circulating vacuum pump does not merely use water for cooling; it uses the moving water itself to create the vacuum. Therefore, the most critical preparation step is correctly filling the reservoir, as the water's level, temperature, and purity directly determine the pump's performance and longevity.

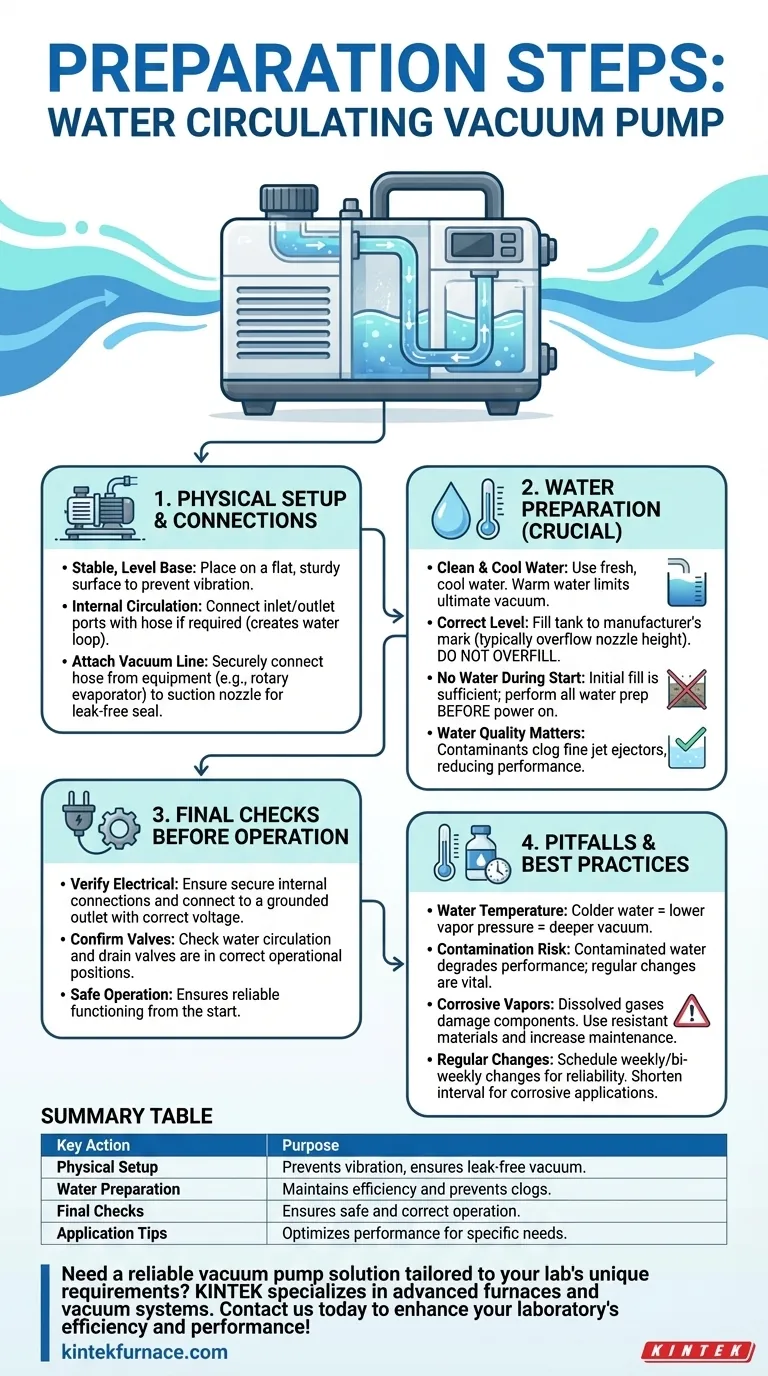

The Foundation: Physical Setup and Connections

Before adding water or power, a correct physical setup prevents operational problems like vibration, noise, and inefficient circulation.

Ensure a Stable, Level Base

Place the pump on a flat, sturdy worktable or floor. An unstable or angled surface can cause excessive vibration and may lead to an inaccurate water level, affecting the pump's efficiency.

Connect Internal Circulation (If Required)

Some models have separate water inlet and outlet ports on the tank that must be connected with a hose. This hose creates the loop that allows the pump to circulate its own water supply. Check your specific model to see if this connection is necessary.

Attach the Vacuum Line

Securely connect the vacuum hose from your apparatus (like a rotary evaporator or filtration setup) to the pump’s suction nozzle. A tight, leak-free seal is essential for achieving a good vacuum.

The Heart of the Pump: Water Preparation

This is the most crucial stage of preparation. The water is not a secondary coolant; it is the primary medium for generating the vacuum via the pump's internal ejectors.

Why Water Quality Matters

The pump creates a vacuum by forcing water through jet ejectors. Any dirt, algae, or mineral scale in the water can clog these fine nozzles, drastically reducing performance and potentially requiring disassembly to clean.

Use Only Clean, Cool Water

Always start with fresh, clean water. For best results, use cool water, as warmer water has a higher vapor pressure, which will limit the ultimate vacuum level the pump can achieve.

Filling to the Correct Level

Open the water tank lid and add water until the level reaches the mark indicated by the manufacturer. This is typically at the height of the overflow nozzle. Do not overfill.

Do Not Add Water While Starting

Once filled, the pump does not require more water to be added during its launch or operation. The phrase "no need to add water when launching" means the initial fill is sufficient; you should perform all water preparation before turning the power on.

Understanding the Pitfalls and Best Practices

Avoiding common mistakes is key to maintaining performance and protecting your investment.

The Impact of Water Temperature

A pump's ultimate vacuum is limited by the vapor pressure of the water inside it. Colder water has a lower vapor pressure, allowing the pump to pull a deeper vacuum. If your process requires a very deep vacuum, starting with chilled water can provide a significant advantage.

The Risk of Contamination

If the water in the tank becomes contaminated, it will circulate those contaminants through the entire pump system. This is the single most common cause of performance degradation.

Handling Corrosive Vapors

If you are using the pump to evacuate corrosive gases (e.g., acids, alkalis), these gases will dissolve into the water. This makes the water corrosive and can damage the pump's internal components. While many pumps are built with resistant materials, this practice demands more frequent maintenance.

The Importance of Regular Water Changes

To ensure optimal vacuum conditions and prevent damage, the water in the tank must be replaced regularly. If you are pumping corrosive vapors or materials that can contaminate the water, you must shorten the replacement interval significantly.

Final Checks Before Operation

With the pump set up and filled, perform these final checks.

Verify Electrical Connections

Open the electric box to ensure all internal connections are secure from shipping. Connect the power cord to an appropriate, grounded electrical outlet that matches the pump's voltage and power requirements.

Confirm All Valves Are Set

Check your pump and its manual for any specific valves related to water circulation or drainage. Ensure they are in the correct position for operation (e.g., drain valve closed) before turning the power switch on.

Preparing for Your Specific Application

Your preparation and maintenance schedule should align with your goals.

- If your primary focus is achieving the deepest possible vacuum: Use cold, deionized, or distilled water to minimize vapor pressure and prevent mineral buildup in the jets.

- If your primary focus is long-term reliability: Establish a strict weekly or bi-weekly schedule for changing the water, even if it appears clean.

- If you are pumping corrosive gases: Prioritize using a pump with a corrosion-resistant body and impeller, and commit to changing the water after every one or two uses to neutralize contaminants.

Proper preparation ensures your water circulating vacuum pump operates as a reliable and precise instrument from the very first use.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Physical Setup | Place pump on stable surface, connect vacuum line | Prevents vibration, ensures leak-free vacuum |

| 2. Water Preparation | Fill with clean, cool water to overflow nozzle | Maintains pump efficiency and prevents clogs |

| 3. Final Checks | Verify electrical connections and valve settings | Ensures safe and correct operation |

| 4. Application Tips | Use cold or distilled water for deep vacuum | Optimizes performance based on specific needs |

Need a reliable vacuum pump solution tailored to your lab's unique requirements? KINTEK specializes in advanced high-temperature furnaces and vacuum systems, offering products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we provide deep customization to precisely match your experimental needs. Contact us today to enhance your laboratory's efficiency and performance!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a quartz tube utilized as the primary reaction vessel? Optimize Microwave-Assisted Metal Recovery Efficiency

- Why are graphite crucible furnaces used in vacuum or protective atmosphere environments? Prevent Oxidation and Ensure Purity

- What is the function of a laboratory hydraulic press in LLZO green body prep? Ensure High Density and Ionic Conductivity

- What key functions do graphite molds perform in RuTi alloy sintering? Achieve High-Density Precision at 1000°C

- What is the function of the substrate heating system for WS2 thin films? Optimize Crystallinity and Adhesion

- What is the role of quartz capillaries in the vacuum sealing process of sulfur? Enhance Purity and In-Situ Analysis

- What is the function of high-purity graphite molds during SPS of Cu2Se? Essential Tips for Superior Sintering

- How can the temperature resistance of alumina ceramic furnace tubes be assessed? Ensure Long-Term Reliability in Your Lab