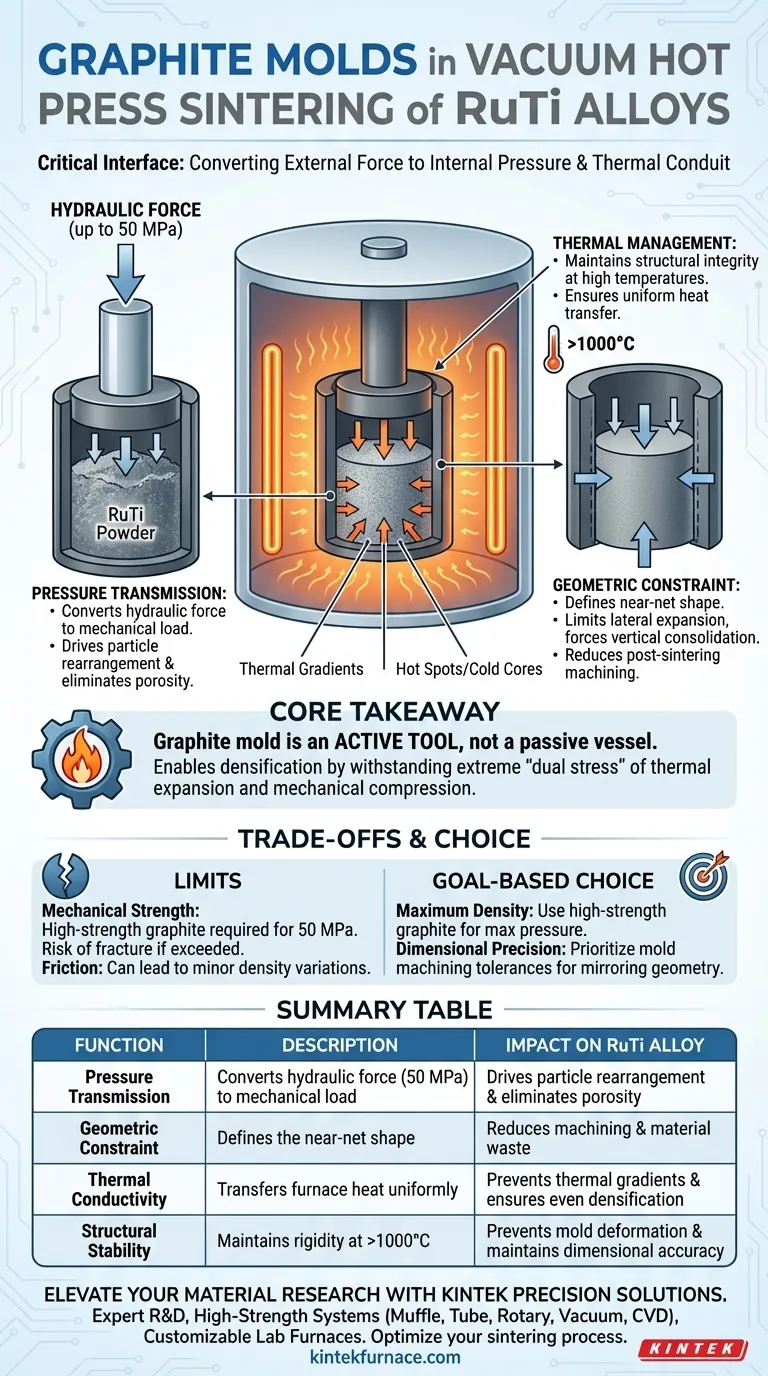

In the vacuum hot press sintering of RuTi alloys, graphite molds act as the critical interface between the furnace environment and the metal powder, serving simultaneously as a geometric container, a pressure transmitter, and a thermal conduit. Their primary function is to convert external hydraulic force (up to 50 MPa) into internal mechanical pressure on the powder while maintaining structural integrity at temperatures exceeding 1000°C.

Core Takeaway The graphite mold is not a passive vessel; it is an active tool that enables the densification of refractory alloys by withstanding the extreme "dual stress" of thermal expansion and mechanical compression. Its ability to conduct heat uniformly while transmitting massive pressure is the decisive factor in converting loose RuTi powder into a solid, high-density alloy block.

Mechanical Constraint and Pressure Transmission

Defining the Component Geometry

At its most fundamental level, the graphite mold serves as a forming and constraining container. It defines the near-net shape of the final RuTi alloy product.

By securely containing the loose powder, the mold limits lateral expansion. This constraint forces the powder to consolidate vertically rather than spreading outward, significantly reducing the need for post-sintering machining.

Transmitting Hydraulic Force

The mold acts as the direct transmission vehicle for the hydraulic system. It must transfer substantial external pressure—specifically 50 MPa for RuTi alloys—directly to the powder body.

This mechanical pressure provides the necessary driving force to overcome the surface tension of the powder particles. It promotes particle rearrangement and plastic deformation, which are essential for eliminating pores in the material.

Thermal Management at High Temperatures

Maintaining Structural Integrity

The sintering process for RuTi requires temperatures above 1000°C. Standard metal molds would soften or melt under these conditions, leading to immediate structural failure.

High-strength graphite is unique because it maintains (and often increases) its strength at these elevated temperatures. It provides a rigid framework that prevents deformation of the alloy during the critical heating phase.

Ensuring Uniform Heat Transfer

Graphite possesses excellent thermal conductivity, which is vital for the quality of the final alloy.

The mold absorbs heat from the furnace elements and transfers it uniformly to the interior of the powder body. This prevents thermal gradients (hot spots or cold cores) within the RuTi powder, ensuring the alloy densifies evenly throughout its volume.

Understanding the Trade-offs

The limit of Mechanical Strength

While graphite is heat-resistant, it is brittle compared to metals. The primary reference notes a requirement for high-strength graphite to handle 50 MPa.

Standard or lower-grade graphite may fracture under this load. If the pressure exceeds the specific graphite grade's limit, the mold will crack, leading to sintering failure and potential damage to the furnace.

Balancing Friction and Containment

The mold provides friction against the powder during compression. While this aids in containment, excessive friction can occasionally lead to density variations near the mold walls compared to the center.

Making the Right Choice for Your Goal

The success of your sintering run depends on matching the mold's capabilities to your specific processing parameters.

- If your primary focus is Maximum Density: Ensure you utilize high-strength graphite capable of withstanding the full 50 MPa pressure to maximize particle deformation without mold fracture.

- If your primary focus is Dimensional Precision: Prioritize the machining tolerances of the graphite mold itself, as the alloy will mirror the mold's internal geometry exactly upon densification.

By leveraging the high-temperature strength and thermal conductivity of graphite, you turn the complex physics of vacuum hot pressing into a reliable manufacturing process.

Summary Table:

| Function | Description | Impact on RuTi Alloy |

|---|---|---|

| Pressure Transmission | Converts hydraulic force (50 MPa) to mechanical load | Drives particle rearrangement and eliminates porosity |

| Geometric Constraint | Defines the near-net shape of the component | Reduces post-sintering machining and material waste |

| Thermal Conductivity | Transfers furnace heat uniformly to the powder core | Prevents thermal gradients and ensures even densification |

| Structural Stability | Maintains rigidity at temperatures >1000°C | Prevents mold deformation and maintains dimensional accuracy |

Elevate Your Material Research with KINTEK Precision Solutions

Don't let inferior tooling compromise your sintering results. KINTEK provides industry-leading thermal technology backed by expert R&D and manufacturing. We offer high-strength Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside customizable high-temperature lab furnaces designed to handle the rigorous demands of refractory alloy production.

Whether you need to withstand 50 MPa pressure or achieve perfect thermal uniformity, our team can customize a solution for your unique needs. Optimize your sintering process—contact KINTEK today!

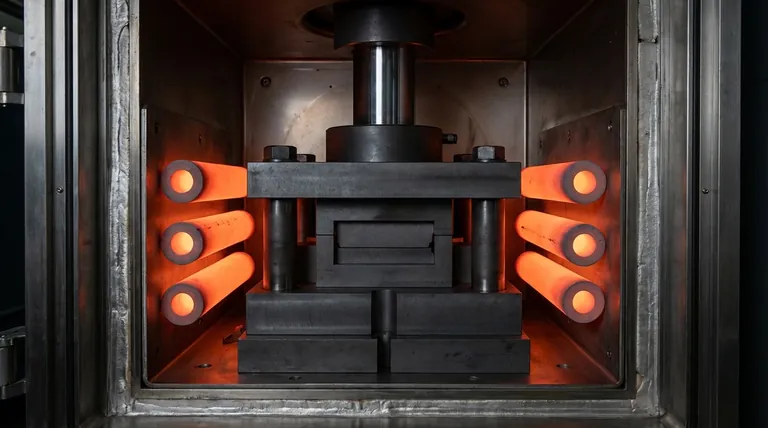

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How do 15x80mm technical openings and seals boost electric furnace efficiency? Maximize Thermal Performance Today

- Why is a high-precision mass flow controller (MFC) necessary in ferronickel alloy smelting? Ensure Metal Purity

- What role do high-purity graphite crucibles play in Boron Carbide sintering? Optimize Ceramic Purity and Density

- Why are Type K thermocouples preferred in industrial furnaces? Unlock Reliable Precision for High-Heat Control

- What role do graphite molds play in the Spark Plasma Sintering (SPS)? Enhance Alumina Composite Performance

- What is the function of high-vacuum quartz sealing tubes in TiCo1-xCrxSb heat treatment? Ensure Alloy Purity

- Why are high-precision mass flow controllers necessary for h-BN CVD growth? Ensure Superior Film Stoichiometry

- What is the primary function of graphitized quartz glass tubes in the synthesis of Bi2Se3-Nd2Se3 alloys?