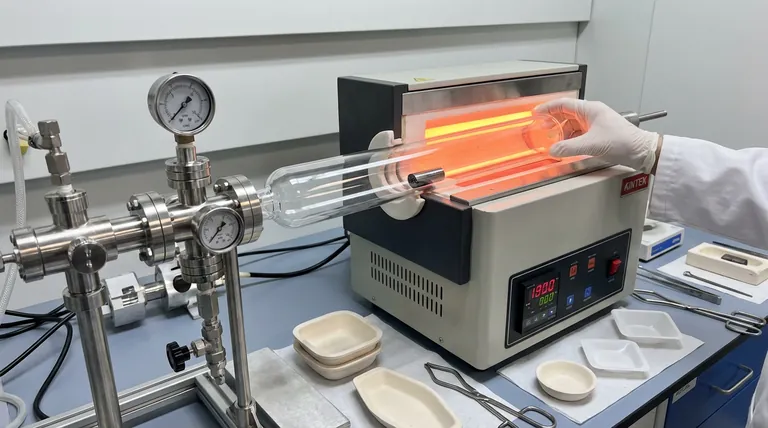

High-vacuum quartz sealing tubes serve as a critical isolation barrier during the heat treatment of TiCo1-xCrxSb alloys. By evacuating the environment to pressures below 1.0 Pa, these tubes prevent chemical degradation and compositional shifts during long-term homogenization annealing.

Core Takeaway The quartz sealing tube acts as a dual-purpose shield: it physically contains volatile elements like antimony (Sb) to maintain the correct alloy ratio, while simultaneously creating a vacuum environment that eliminates the risk of severe oxidation common in standard high-temperature furnaces.

Preserving Chemical Integrity

Preventing Atmospheric Oxidation

Standard muffle furnaces expose materials to oxygen, which can be disastrous for Titanium-based alloys.

Without protection, TiCo1-xCrxSb samples suffer from severe oxidation and surface contamination.

The quartz tube, evacuated to high vacuum (< 1.0 Pa), removes reactive gases, ensuring the material remains pure and maintains its surface brightness.

Controlling Volatile Components

The specific chemistry of TiCo1-xCrxSb relies on precise ratios of its constituent elements.

Antimony (Sb) is particularly volatile and prone to evaporation or sublimation at the high temperatures required for annealing.

Sealing the alloy inside the quartz tube traps these vapors, stopping the loss of Sb and ensuring the final phase structure matches the intended stoichiometry.

Facilitating Long-Term Homogenization

The Need for Extended Stability

Creating a uniform alloy structure requires "homogenization annealing," a process that often takes a significant amount of time.

High-vacuum tubes provide the stable, inert environment necessary for this long-duration processing.

They allow the material to be held at high temperatures without the cumulative degradation that would occur in an open system.

Temperature Resilience

While the vacuum handles the chemistry, the quartz material itself handles the thermal load.

It effectively encapsulates the sample during high-temperature holding phases (potentially exceeding 1000°C), acting as a physical barrier against the furnace atmosphere.

Operational Considerations and Trade-offs

Vacuum Integrity is Paramount

The effectiveness of this method relies entirely on the quality of the seal and the depth of the vacuum.

If the pressure rises above 1.0 Pa due to a leak or poor sealing, the protective mechanism fails, leading to immediate oxidation.

Managing Internal Pressure

While the vacuum protects the sample, the volatility of antimony can create internal pressure within the sealed tube.

Operators must ensure the quartz tube has sufficient wall thickness and structural integrity to withstand the vapor pressure generated by volatile components during the heating cycle.

Ensuring Successful Heat Treatment

To apply this to your material synthesis effectively, consider the following regarding your specific goals:

- If your primary focus is compositional accuracy: Ensure the tube is sealed tightly to prevent any escape of Antimony (Sb) vapor, as even minor losses will alter the $x$ value of your alloy.

- If your primary focus is surface quality: Verify that your vacuum pump achieves a baseline pressure consistently below 1.0 Pa to prevent the formation of oxide layers.

Success in synthesizing TiCo1-xCrxSb relies on treating the encapsulation process as strictly as the heating profile itself.

Summary Table:

| Feature | Function in TiCo1-xCrxSb Treatment | Benefit to Material |

|---|---|---|

| High Vacuum (<1.0 Pa) | Removes atmospheric oxygen and reactive gases | Prevents oxidation and surface contamination |

| Quartz Encapsulation | Physical barrier against furnace atmosphere | Enables high-temperature resilience (1000°C+) |

| Hermetic Sealing | Traps volatile elements like Antimony (Sb) | Maintains stoichiometry and phase structure |

| Inert Environment | Stabilizes sample during long-term annealing | Ensures uniform homogenization and purity |

Elevate Your Material Synthesis with KINTEK

Precision heat treatment of advanced alloys like TiCo1-xCrxSb demands more than just heat—it requires a controlled environment. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing.

Whether you need specialized CVD systems, high-temperature vacuum furnaces, Muffle, Tube, or Rotary systems, our equipment is fully customizable to meet your unique laboratory requirements. Ensure compositional accuracy and eliminate oxidation in your research today.

Ready to optimize your annealing process? Contact KINTEK for a custom solution

References

- Volodymyr Krayovskyy, А. Horyn. SIMULATION OF CHARACTERISTICS OF SENSITIVE ELEMENTS OF TEMPERATURE CONVERTERS BASED ON TiCo1-xCrxSb. DOI: 10.23939/istcmtm2024.04.030

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What role does a high-precision mass flow controller play in assessing the gas selectivity of Gallium Sulfide sensors?

- What functions does the hot pressing mold perform? Key Roles in Al3Ti/Al Composite Powder Metallurgy

- What are the primary functions of high-purity graphite molds in the SPS of TiB2 ceramics? Enhance Sintering Precision

- Why is a PTFE-lined stainless steel autoclave used for Ni12P5 synthesis? Key Benefits for Nanomaterial Production

- What is the function of an alumina boat during high-temperature activation of porous carbon? Durable Lab Solutions

- What are the primary functions of a Quartz Flow Reactor? Enhance Precision in Oxidation Research

- How do graphite sleeves and ceramic crucibles function in induction furnaces? Key Roles in Material Synthesis

- What should be evaluated when assessing supplier reliability for alumina ceramic furnace tubes? Ensure Consistent Performance and Support