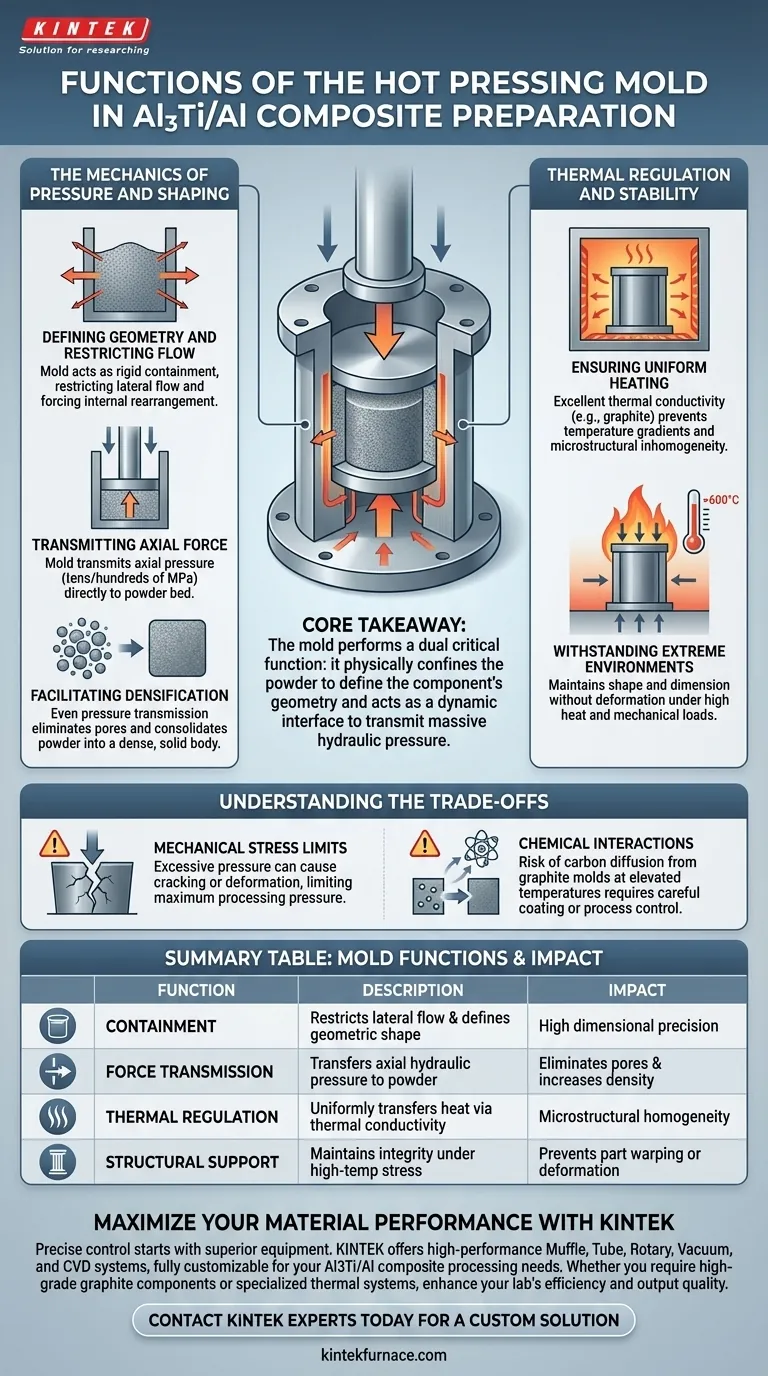

The hot pressing mold serves as the definitive containment vessel and force transmitter in the powder metallurgy process. During the preparation of Al3Ti/Al composites, it acts as the primary medium to transfer externally applied axial pressure to the internal powders while simultaneously dictating the final dimensions of the green body.

Core Takeaway The mold performs a dual critical function: it physically confines the powder to define the component's geometry and acts as a dynamic interface to transmit massive hydraulic pressure. To succeed, the mold material (typically graphite) must maintain structural integrity and chemical stability under extreme heat and mechanical stress to ensure uniform densification.

The Mechanics of Pressure and Shaping

Defining Geometry and Restricting Flow

The most immediate function of the mold is to define the geometric shape and dimensions of the final Al3Ti/Al composite product.

By acting as a rigid containment vessel, the mold restricts the lateral flow of the metal powder. This confinement is essential because it forces the powder particles to rearrange and densify internally rather than spreading outward under pressure.

Transmitting Axial Force

The mold acts as the transmission medium between the external press and the internal powder.

As the hydraulic press applies force, the mold transmits this axial pressure (often tens or hundreds of MPa) directly to the powder bed. This transmission must remain effective even as the powder volume shrinks during consolidation.

Facilitating Densification

Effective pressure transmission is the prerequisite for achieving high-performance physical bonding.

By transferring pressure evenly, the mold ensures tight contact between the matrix (Al) and reinforcement (Al3Ti) phases. This process eliminates pores and consolidates the loose powder into a dense, solid body approaching theoretical density limits.

Thermal Regulation and Stability

Ensuring Uniform Heating

Beyond mechanical functions, the mold plays a vital role in thermal regulation.

Graphite molds, frequently used in this process, possess excellent thermal conductivity. This allows the mold to transfer heat uniformly to the internal sample, preventing temperature gradients that could lead to microstructural inhomogeneity or inconsistent material properties.

Withstanding Extreme Environments

The mold must possess exceptional high-temperature strength to survive the processing environment.

It is required to maintain its shape and dimension without deforming while subjected to high heat (often exceeding 600°C for Aluminum composites and up to 1200°C for others) and massive mechanical loads. A failure in thermal stability would result in a warped product or a catastrophic failure of the containment.

Understanding the Trade-offs

Mechanical Stress Limits

While the mold is designed to withstand pressure, it is not indestructible.

If the applied pressure exceeds the mold material's compressive strength—particularly at peak temperatures—the mold can crack or deform. This limits the maximum pressure you can apply to the Al3Ti/Al composite during processing.

Chemical Interactions

The mold must remain chemically stable relative to the powder mixture.

At elevated temperatures, there is a risk of carbon diffusion from a graphite mold into the metal matrix. This requires careful selection of mold coatings or process parameters to prevent unwanted surface reactions that could degrade the composite's purity.

Making the Right Choice for Your Goal

To ensure the successful preparation of Al3Ti/Al composites, consider the following based on your specific objectives:

- If your primary focus is Dimensional Precision: Prioritize a mold material with the highest possible thermal stability and compressive strength to prevent even micro-deformations during the holding phase.

- If your primary focus is Microstructural Homogeneity: Select a mold material with superior thermal conductivity (like high-grade graphite) to ensure the core and surface of the composite heat at the same rate.

The quality of your final composite is ultimately limited by the structural and thermal integrity of the mold you choose to contain it.

Summary Table:

| Function | Description | Impact on Final Composite |

|---|---|---|

| Containment | Restricts lateral flow & defines geometric shape | High dimensional precision |

| Force Transmission | Transfers axial hydraulic pressure to powder | Eliminates pores & increases density |

| Thermal Regulation | Uniformly transfers heat via thermal conductivity | Microstructural homogeneity |

| Structural Support | Maintains integrity under high-temp stress | Prevents part warping or deformation |

Maximize Your Material Performance with KINTEK

Precise control in powder metallurgy starts with superior equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to meet your unique Al3Ti/Al composite processing needs.

Whether you require high-grade graphite components or specialized thermal systems, our team is ready to enhance your lab's efficiency and output quality.

Contact KINTEK experts today for a custom solution

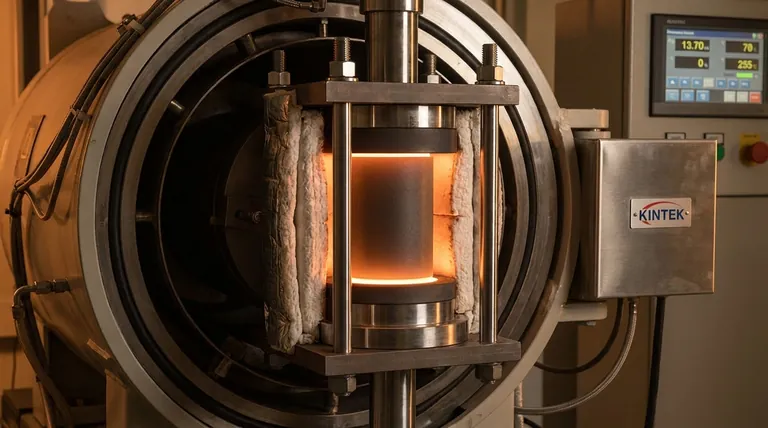

Visual Guide

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the primary uses of quartz tubes in laboratory settings? Essential for High-Temperature Material Processing

- Why are laboratory hydraulic presses critical for FMDS pelletization? Boost Strength Without Heat

- Why is the use of high-purity graphite crucibles essential? Protect TiC-High Manganese Steel During Sintering

- What is the function of graphite stirring rods in aluminum casting? Achieve Perfect Alloy Homogenization

- What are the specific functions of the grinder and laboratory oven during sugarcane-based activated carbon preparation?

- What is the function of a vacuum ampoule during the synthesis of ZnGeP2? Ensure Purity and Chemical Stability

- Why is a vacuum drying oven essential for Pd-Ni/ZrO2 catalyst preparation? Ensure Uniform Metal Distribution

- What is the primary function of a high-purity vacuum-sealed quartz tube in the Modified Bridgman technique? Key Role