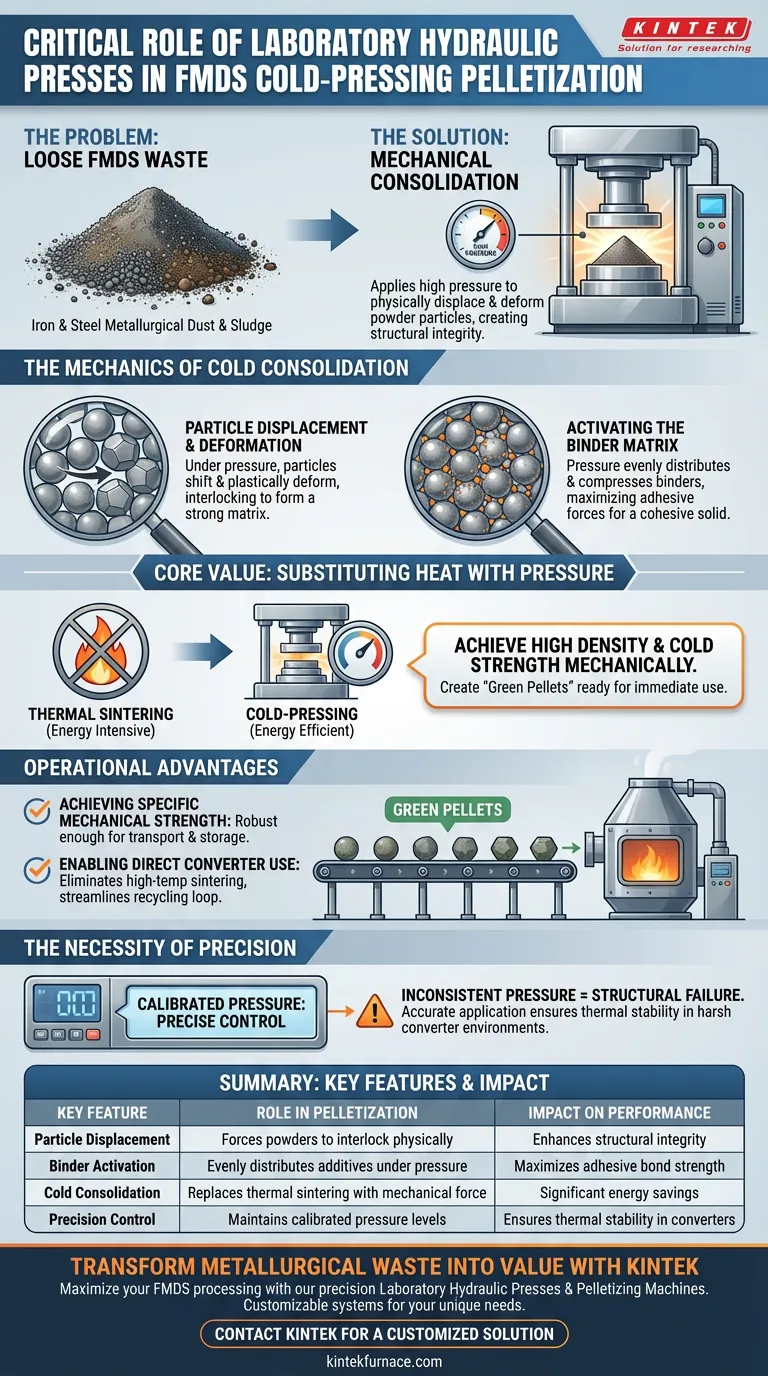

Laboratory hydraulic presses and pelletizing machines are the fundamental drivers of mechanical consolidation in FMDS processing. These machines apply the high pressure necessary to physically displace and deform powder particles found in Iron and Steel Metallurgical Dust and Sludge (FMDS). By forcing these particles together to interlock, these machines generate the structural integrity required to turn loose waste powder into usable industrial pellets.

The core value of these machines is their ability to substitute heat with pressure. By achieving high density through mechanical force rather than thermal sintering, they allow for the energy-efficient creation of "green pellets" that are immediately ready for use in converters.

The Mechanics of Cold Consolidation

Particle Displacement and Deformation

The primary function of the hydraulic press is to manipulate the microstructure of the dust and sludge. Under high pressure, the powder particles are forced to shift positions and pack tightly together.

Beyond simple packing, the force causes the particles to plastically deform. This deformation increases the contact area between particles, creating a physically interlocked matrix that is far stronger than loose powder.

Activating the Binder Matrix

Pressure is the catalyst that makes binders effective. The reference highlights that the process works "combined with binders" to form the final product.

The machine ensures the binder is distributed and compressed evenly among the FMDS particles. This compression maximizes the adhesive forces, turning a mixture of dust and additives into a cohesive solid.

Operational Advantages in Metallurgy

Achieving Specific Mechanical Strength

The ultimate goal of using these machines is to produce "green pellets" with precise mechanical properties. The pressure applied determines the final density and cold strength of the pellet.

Without sufficient pressure, the pellets would be too fragile to handle. The hydraulic press ensures the pellets are robust enough to withstand transport and storage without crumbling.

Enabling Direct Converter Use

The most significant operational benefit is the elimination of high-temperature sintering. Because the press provides sufficient "cold strength" and thermal stability mechanically, the pellets are ready for immediate use.

They can be introduced directly into converters as coolants or slagging agents. This bypasses energy-intensive heating steps, streamlining the recycling loop for metallurgical waste.

Understanding the Constraints

The Necessity of Precision

While high pressure is critical, "precise pressure control" is the defining factor for success. This is not a brute-force operation; it requires specific calibration.

If the pressure is inconsistent, the pellets may lack the required thermal stability. Inaccurate pressure application leads to pellets that fail structurally when introduced to the harsh environment of a converter.

Making the Right Choice for Your Goal

To optimize your FMDS pelletization process, consider the following based on your specific operational targets:

- If your primary focus is Energy Efficiency: Utilize presses capable of achieving high density at ambient temperatures to completely eliminate the need for downstream sintering.

- If your primary focus is Product Reliability: Prioritize machines with advanced pressure control systems to ensure every pellet meets the specific cold strength requirements for converter injection.

Precise mechanical compression is the key to transforming metallurgical waste into valuable raw materials without the cost of thermal processing.

Summary Table:

| Key Feature | Role in FMDS Pelletization | Impact on Performance |

|---|---|---|

| Particle Displacement | Forces powders to interlock physically | Enhances structural integrity |

| Binder Activation | Evenly distributes additives under pressure | Maximizes adhesive bond strength |

| Cold Consolidation | Replaces thermal sintering with mechanical force | Significant energy savings |

| Precision Control | Maintains calibrated pressure levels | Ensures thermal stability in converters |

Transform Your Metallurgical Waste into Value

Maximize the potential of your FMDS processing with KINTEK. As a leader in laboratory high-temp and mechanical solutions, we provide the precision Laboratory Hydraulic Presses and Pelletizing Machines needed to create high-density green pellets with superior cold strength.

Backed by our expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet your unique industrial requirements. Let our technology help you eliminate energy-intensive sintering and streamline your recycling loop.

Ready to optimize your pelletization process? Contact KINTEK today for a customized solution.

Visual Guide

References

- Jiansong Zhang, Qianqian Ren. Multi-Source Ferrous Metallurgical Dust and Sludge Recycling: Present Situation and Future Prospects. DOI: 10.3390/cryst14030273

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- Why is a laboratory vacuum drying oven necessary for processing nano MOFs? Preserve nLn-bdc Structural Integrity

- What is the importance of the quartz boat in BPEA crystal growth? Essential for Purity and Performance

- What is the significance of using ceramic or quartz sample boats for solid fuels? Ensure Precise Thermal Analysis

- What is the primary function of an alumina crucible in preparing B2O3–ZnO–BaO shielding glass? Process Secrets Revealed

- Why use high-purity graphite for β-Ga2O3 annealing? Key to Thermal Precision & Safety

- What role does a Molybdenum Boat play in ZTO thin film deposition? Master Thermal Evaporation Success

- What is the primary function of vacuum quartz tubes in Bi-Sb alloy preparation? Ensure Purity & Precise Stoichiometry

- What customization options are available for alumina ceramic tubes? Tailor for High-Temp, Corrosion-Resistant Applications