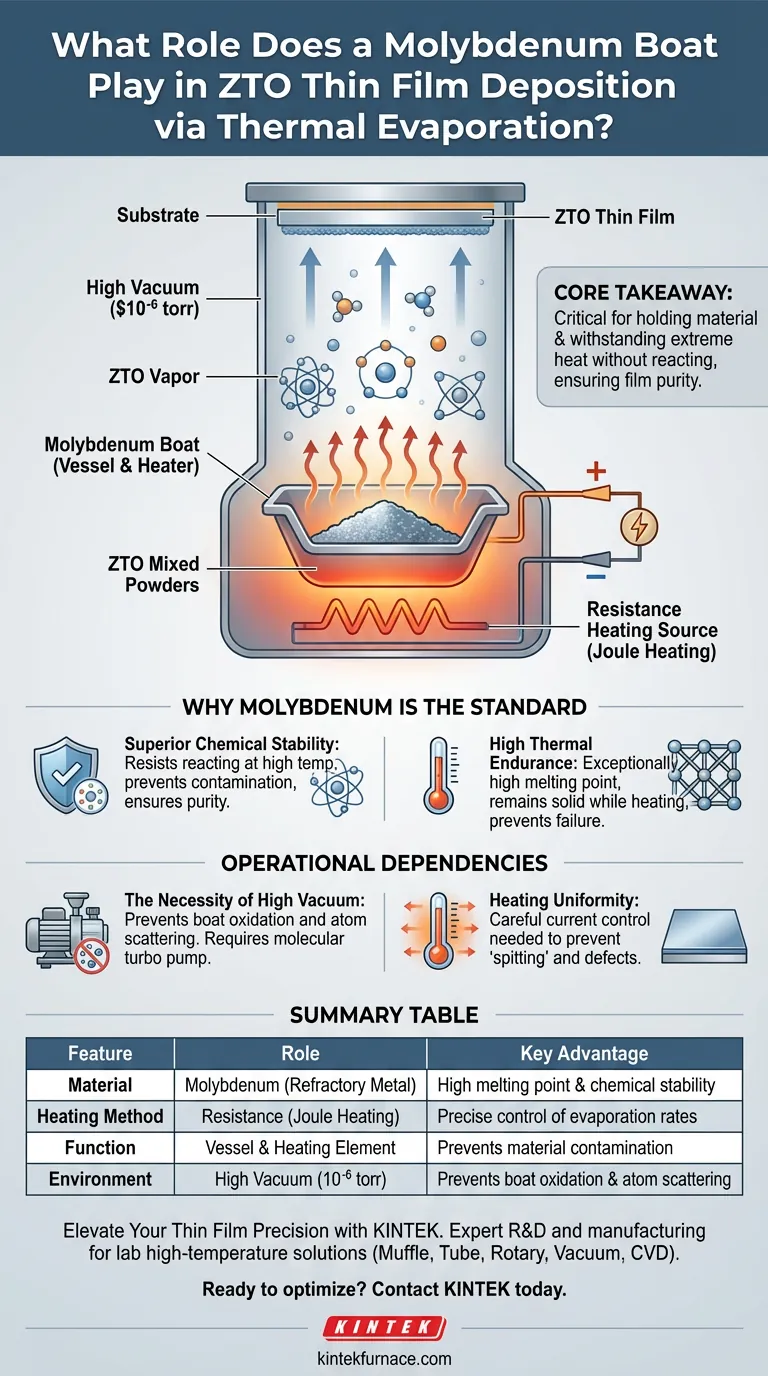

The Molybdenum Boat functions as both the physical vessel and the active heating element required to deposit Zinc Tin Oxide (ZTO) thin films via thermal evaporation. By passing a high electrical current through the boat, it serves as a resistance heater that raises the temperature of the ZTO mixed powders until they sublime or evaporate, transitioning into a gas phase that coats the target substrate.

Core Takeaway The Molybdenum Boat is critical not just for holding the source material, but for its ability to withstand extreme heat without chemically reacting with the ZTO powder. This ensures the deposited film remains pure and is not contaminated by the boat material itself.

The Mechanics of Thermal Deposition

Resistance Heating Source

The fundamental role of the Molybdenum Boat is to convert electrical energy into thermal energy.

When a high electrical current is passed through the boat, its inherent electrical resistance generates intense heat. This process, known as Joule heating, allows the boat to reach the specific evaporation temperature required by the ZTO powder.

Phase Transition Control

The heat generated by the boat is transferred directly to the ZTO mixed powders it holds.

As the temperature rises, the powder undergoes a phase change, sublimating or evaporating into a vapor. This vapor travels through the vacuum chamber to settle on the substrate, forming the thin film.

Why Molybdenum is the Standard

Superior Chemical Stability

In thin film deposition, maintaining material purity is paramount.

Molybdenum possesses excellent chemical stability, meaning it is highly resistant to reacting with other elements even at high temperatures. This prevents the boat from contaminating the ZTO vapor, ensuring the stoichiometry of the deposited layer matches the source material.

High Thermal Endurance

The evaporation process requires temperatures that would melt or deform lesser metals.

Molybdenum has an exceptionally high melting point. This allows it to remain structurally sound and solid while heating the ZTO powder to its evaporation point, preventing catastrophic failure of the heating element during the process.

Operational Dependencies and Trade-offs

The Necessity of High Vacuum

While the Molybdenum Boat is robust, its performance is strictly tied to the vacuum environment.

As noted in standard vacuum practices, a molecular turbo pump is required to achieve a high vacuum (around $10^{-6}$ torr). Without this ultra-high vacuum, oxygen in the air would not only scatter the evaporated ZTO atoms but could also cause the hot Molybdenum boat to oxidize and degrade rapidly.

Heating Uniformity

The geometry of the boat dictates how evenly the ZTO powder is heated.

If the boat is packed unevenly or if the current is ramped up too quickly, "spitting" of the powder can occur. This results in defects on the film surface, necessitating careful control of the input current.

Making the Right Choice for Your Goal

To ensure successful ZTO deposition, consider these operational priorities:

- If your primary focus is Film Purity: Ensure the Molybdenum Boat is thoroughly cleaned before loading to leverage its chemical stability and prevent cross-contamination.

- If your primary focus is Deposition Rate: Regulate the electrical current precisely; higher current increases the evaporation rate, but risking the boat's structural integrity if pushed beyond its thermal limits.

Mastering the thermal characteristics of the Molybdenum Boat is the first step toward achieving consistent, high-quality ZTO thin films.

Summary Table:

| Feature | Role in ZTO Deposition | Key Advantage |

|---|---|---|

| Material | Molybdenum (Refractory Metal) | High melting point & chemical stability |

| Heating Method | Resistance (Joule Heating) | Precise control of evaporation rates |

| Function | Vessel & Heating Element | Prevents material contamination |

| Environment | High Vacuum ($10^{-6}$ torr) | Prevents boat oxidation & atom scattering |

Elevate Your Thin Film Precision with KINTEK

Achieving high-purity ZTO thin films requires more than just high-quality materials—it requires the right heating environment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of laboratory high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems.

Whether you need standard equipment or a customizable system tailored to your unique deposition needs, our expert team is here to support your research and production goals.

Ready to optimize your thermal processes? Contact KINTEK today to consult with our engineering experts.

Visual Guide

References

- Ashish Khandelwal, K. S. Sharma. Effect of Different Compositions of Mixed Metal Oxides (Zinc Oxide and Tin Oxide) on Structural and Optical Properties for the Application of Window Layers in Solar Cells. DOI: 10.3329/jsr.v16i1.64157

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a precise gas flow control and supply system necessary during the thermochemical conversion of rice husk biochar?

- How does surface finish impact the performance of alumina ceramic furnace tubes? Boost Purity and Efficiency

- What is the purpose of using a high-purity quartz boat? Ensure Sample Purity in TiO2@C High-Temp Annealing

- Why is a BN coating used in Mg3Sb2 melting? Essential Purity and Protection Guide

- How does a PID temperature controller facilitate gasification research? Unlock Precision in Industrial Simulations

- Why is a laboratory vacuum drying oven necessary for processing nano MOFs? Preserve nLn-bdc Structural Integrity

- Why is a laboratory oven utilized during the pre-treatment stage of chicken bone waste pyrolysis?

- How do vacuum filtration systems operate in industrial sludge dehydration? Achieve Efficient Liquid-Solid Separation