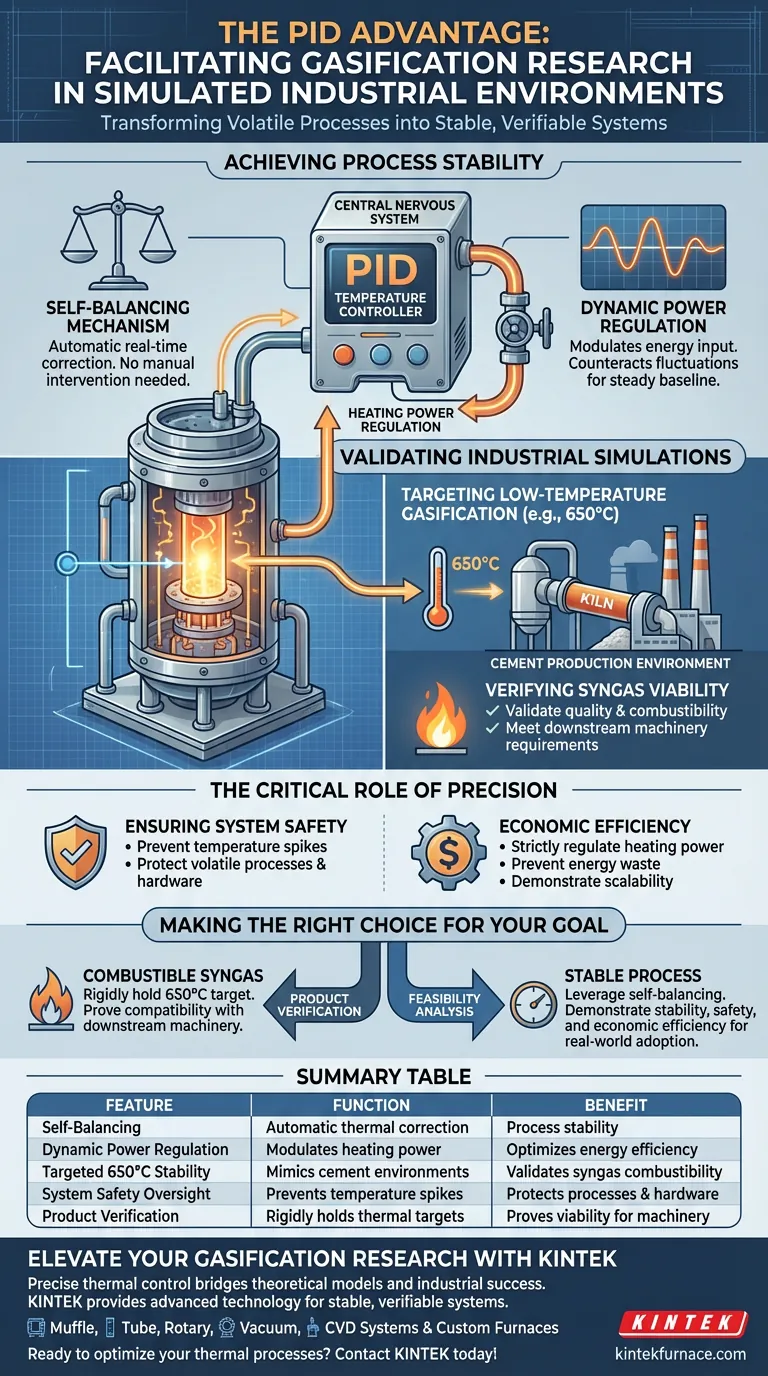

A PID temperature controller acts as the central nervous system for gasification reactors, facilitating research by maintaining a "self-balancing" state through the precise regulation of heating power. in the context of simulated industrial environments, such as cement production, this automation ensures the reactor holds specific low-temperature targets (e.g., 650°C) to validate the quality and combustibility of the resulting syngas.

By automating thermal regulation, the PID controller transforms a volatile chemical process into a stable, verifiable system. This precision allows researchers to prove that syngas generated at lower temperatures is both safe to produce and potent enough to power downstream industrial machinery.

Achieving Process Stability

The Mechanism of Self-Balancing

The fundamental role of the PID controller in this setting is to maintain the reactor in a self-balancing state. This means the system automatically corrects itself without the need for constant manual adjustment.

Dynamic Power Regulation

To achieve this equilibrium, the controller directly regulates the heating power supplied to the reactor. It modulates energy input in real-time to counteract thermal fluctuations, ensuring a steady operational baseline.

Validating Industrial Simulations

Targeting Low-Temperature Gasification

Research often requires simulating specific, non-standard environments to test feasibility. The PID controller enables the reactor to maintain precise low-temperature conditions, specifically around 650°C, which mimics processes like cement production.

Verifying Syngas Viability

Precision at these specific temperatures is critical for product validation. It allows researchers to determine if the syngas produced under these conditions meets the strict combustion requirements of downstream equipment.

The Critical Role of Precision

Ensuring System Safety

Gasification involves complex thermal reactions that can become hazardous if uncontrolled. The PID controller improves the safety of the system by preventing temperature spikes that could lead to equipment failure or unsafe operating conditions.

Economic Efficiency

Beyond safety, the controller plays a vital role in the economic viability of the research. By strictly regulating heating power and preventing energy waste, the system demonstrates the economic efficiency required for potential industrial scale-up.

Making the Right Choice for Your Goal

To maximize the value of your gasification research, consider how you apply the PID controller's capabilities:

- If your primary focus is Product Verification: Configure the controller to hold the 650°C target rigidly to prove the syngas is combustible and compatible with downstream machinery.

- If your primary focus is Feasibility Analysis: Leverage the self-balancing capability to demonstrate that the process is stable, safe, and economically efficient enough for real-world adoption.

Precise thermal control is the bridge that turns theoretical gasification models into practical, scalable industrial solutions.

Summary Table:

| Feature | Function in Gasification Research | Benefit for Industrial Simulation |

|---|---|---|

| Self-Balancing Control | Automatic real-time thermal correction | Ensures process stability without manual intervention |

| Dynamic Power Regulation | Modulates heating power to counter fluctuations | Optimizes energy efficiency and prevents thermal spikes |

| Targeted 650°C Stability | Mimics cement production environments | Validates syngas combustibility at lower temperatures |

| System Safety Oversight | Prevents equipment-damaging temperature spikes | Protects volatile chemical processes and hardware |

| Product Verification | Rigidly holds specific thermal targets | Proves viability for downstream industrial machinery |

Elevate Your Gasification Research with KINTEK

Precise thermal control is the bridge between theoretical models and scalable industrial success. KINTEK provides the advanced technology needed to turn complex gasification processes into stable, verifiable systems. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other high-temperature laboratory furnaces—all fully customizable to meet your unique research specifications.

Whether you are verifying syngas viability or conducting feasibility analyses for cement production simulations, our equipment ensures the safety, economic efficiency, and precision your project demands.

Ready to optimize your thermal processes? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Chen Dai, Cai Yu. Characteristics of Low-Temperature Gasification Products from Wheat Straw in a Fluidized Bed Based on Cement Production Process. DOI: 10.3390/en17081943

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the advantage of the circulating water multifunctional vacuum pump being one machine for multiple purposes? Streamline Lab Work Efficiently

- What is the wear resistance of alumina ceramics compared to manganese steel and high-chromium cast iron? Discover the Superior Choice for Abrasive Environments

- What are the key properties of quartz tubes that make them versatile across industries? Discover Their Thermal, Chemical, and Optical Benefits

- How does insulation affect laboratory furnace design? Optimize Thermal Performance and Safety

- What role does a graphite crucible play during alloy and ceramic shell interaction experiments? Optimize Your Lab Results

- Why are vacuum filtration devices and specific cellulose filter papers used in hydrothermal synthesis recovery?

- What is the role of High-Strength Graphite Molds in Al-Ti-Zr sintering? Mastering Vacuum Hot Pressing Performance

- What are the advantages of using graphite for Sb2S3 sulfurization? Enhancing Thermal Precision and Safety