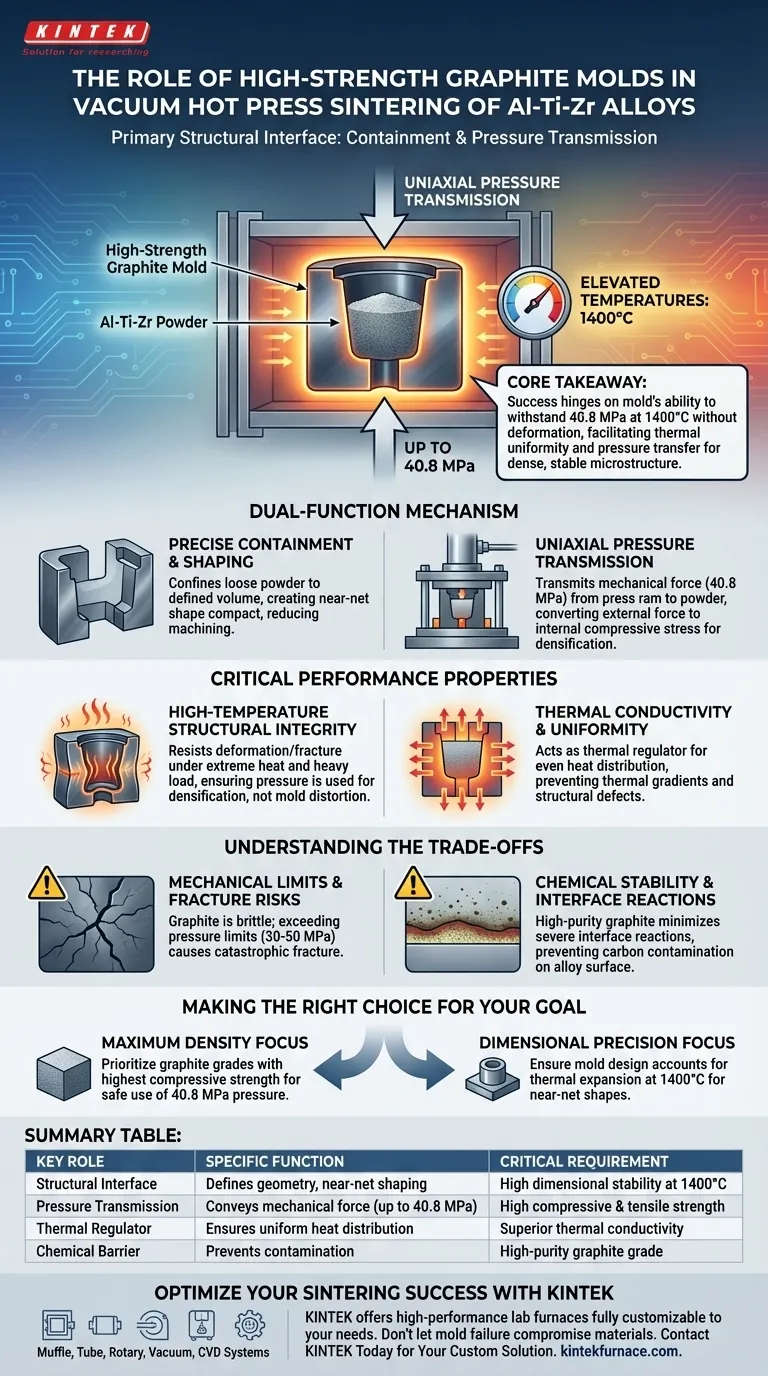

High-Strength Graphite Molds act as the primary structural interface in the vacuum hot press sintering of Al-Ti-Zr alloys. Their role is twofold: they serve as the containment vessel to define the sample's geometry and act as the transmission medium for the immense mechanical force required to densify the powder. Without these specialized molds, it is impossible to apply the necessary uniaxial pressure at elevated sintering temperatures.

Core Takeaway The success of sintering Al-Ti-Zr alloys hinges on the mold's ability to withstand specific extremes—typically 40.8 MPa at 1400°C—without deforming. The mold does not just hold the powder; it facilitates the thermal uniformity and pressure transfer required to eliminate pores and achieve a dense, stable microstructure.

The Dual-Function Mechanism

Precise Containment and Shaping

The most immediate function of the graphite mold is to act as a shaping container. It confines the loose Al-Ti-Zr powder into a defined volume.

Because the mold remains rigid throughout the process, it creates a "near-net shape" compact. This significantly reduces the need for extensive machining after the alloy has cooled.

Uniaxial Pressure Transmission

In vacuum hot pressing, the hydraulic system does not press the powder directly; it presses the mold assembly. The mold must effectively transmit this mechanical force from the press ram to the powder body.

For Al-Ti-Zr alloys, this involves transmitting pressures as high as 40.8 MPa. The mold converts this external hydraulic force into the internal compressive stress needed to force the powder particles together and eliminate voids.

Critical Performance Properties

High-Temperature Structural Integrity

The defining characteristic of these molds is their ability to resist deformation or fracture under extreme conditions. Standard materials would soften or shatter under the combination of high heat and heavy load.

For this specific alloy, the mold maintains its dimensions and strength at temperatures around 1400°C. This ensures that the pressure applied is used for densification rather than deforming the mold walls.

Thermal Conductivity and Uniformity

Graphite provides excellent thermal conductivity, which is vital for process stability. It acts as a thermal regulator, ensuring that heat is distributed evenly across the entire sample.

This prevents thermal gradients that could lead to uneven sintering or microscopic structural defects. Uniform heating allows the Al-Ti-Zr alloy to achieve consistent properties throughout the sintered body.

Understanding the Trade-offs

Mechanical Limits and Fracture Risks

While "high-strength" is the standard, graphite is brittle by nature. There is a hard limit to the hydraulic pressure the mold can withstand before it suffers catastrophic failure.

If the pressure requirements for full densification exceed the mold's material limits (often capped between 30-50 MPa depending on the grade), the mold will fracture. You must balance the need for high pressure against the tensile strength of the specific graphite grade used.

Chemical Stability and Interface Reactions

While generally stable, graphite can react with certain metal powders at high temperatures.

High-purity graphite is essential to act as a barrier that minimizes severe interface reactions. Using lower-quality graphite can lead to carbon contamination on the surface of the Al-Ti-Zr alloy, compromising the material's purity.

Making the Right Choice for Your Goal

To maximize the quality of your Al-Ti-Zr sintering process, align your mold selection with your specific technical objectives:

- If your primary focus is Maximum Density: Prioritize graphite grades with the highest possible compressive strength to safely utilize the full 40.8 MPa pressure required for pore elimination.

- If your primary focus is Dimensional Precision: Ensure the mold design accounts for thermal expansion at 1400°C to achieve near-net shapes and minimize post-sintering machining costs.

Ultimately, the graphite mold is not just a consumable container, but an active component that dictates the thermal and mechanical limits of your sintering process.

Summary Table:

| Key Role | Specific Function | Critical Requirement |

|---|---|---|

| Structural Interface | Defines sample geometry and provides near-net shaping | High dimensional stability at 1400°C |

| Pressure Transmission | Conveys mechanical force (up to 40.8 MPa) for densification | High compressive & tensile strength |

| Thermal Regulator | Ensures uniform heat distribution throughout the alloy | Superior thermal conductivity |

| Chemical Barrier | Prevents contamination of the Al-Ti-Zr microstructure | High-purity graphite grade |

Optimize Your Sintering Success with KINTEK

Precision in Al-Ti-Zr alloy production requires more than just high temperatures—it demands the right thermal and mechanical environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to your unique research or production needs.

Don't let mold failure or thermal gradients compromise your materials. Let our experts help you select the ideal system and configuration to achieve maximum density and dimensional precision.

Contact KINTEK Today to Discuss Your Custom Solution

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the role of a BN crucible in Ca0.5Sr0.5AlSiN3:Eu2+ synthesis? Achieve High-Purity Nitride Phosphors

- How is an alumina crucible utilized during the 1100°C sintering of Indium-doped LLZO? Expert Precautions Explained

- Why is it necessary to achieve a vacuum level of 3 x 10^-2 mm Hg for quartz tube sealing? Ensure Safety and Purity

- What role does a mass flow controller (MFC) play in gas distribution? Ensure Precision in Sensor Performance Evaluation

- What are the placement requirements for high-precision standard thermocouples? Master Sensor Calibration Accuracy

- How is a precision gas flow control system configured for calcium carbonate decomposition? Master Industrial Kinetics

- Why are alumina or ceramic crucibles selected for KCdCl3 perovskite? Ensure High Purity and Thermal Stability

- What temperature range can graphite crucible furnaces withstand? Achieve Extreme Heat for High-Melting Metals