Alumina or ceramic crucibles are chosen primarily for their exceptional chemical inertness and thermal stability. When synthesizing KCdCl3 perovskite, these vessels withstand high calcination temperatures without deforming or decomposing. Crucially, they remain non-reactive, preventing the vessel material from leaching into the compound and ensuring the final polycrystalline solid remains pure.

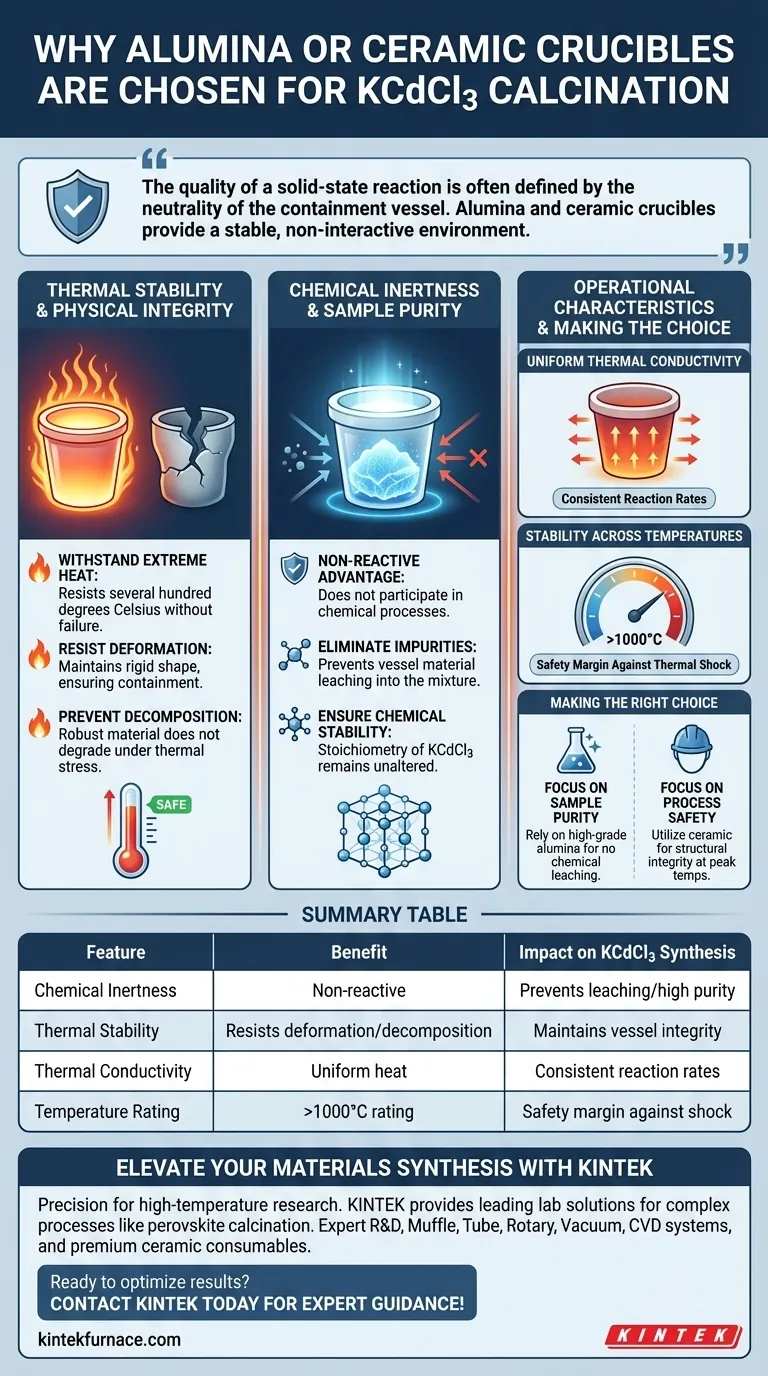

The quality of a solid-state reaction is often defined by the neutrality of the containment vessel. Alumina and ceramic crucibles provide a stable, non-interactive environment that protects the structural integrity and chemical purity of KCdCl3 during rigorous heat treatments.

Thermal Stability and Physical Integrity

Withstanding Extreme Heat

The calcination of KCdCl3 requires sustained exposure to high temperatures. Alumina and ceramic crucibles are capable of withstanding these conditions—often reaching several hundred degrees Celsius—without failure.

Resistance to Deformation

At these elevated temperatures, lesser materials might soften or warp. Ceramic crucibles maintain their rigid shape, ensuring the reaction remains safely contained throughout the heating cycle.

Preventing Decomposition

Unlike some reaction vessels that may break down under thermal stress, alumina remains physically robust. It does not undergo chemical decomposition, which ensures the vessel itself does not degrade during the process.

Chemical Inertness and Sample Purity

The Non-Reactive Advantage

The primary danger in high-temperature synthesis is unintended reactions between the vessel and the sample. Alumina crucibles possess a non-reactive nature, meaning they do not participate in the chemical process.

Eliminating Impurities

Because the crucible resists chemical attack, it prevents foreign elements from leaching into the KCdCl3 mixture. This is vital for synthesizing a high-quality polycrystalline solid free of external contaminants.

Ensuring Chemical Stability

The inertness of the crucible guarantees that the stoichiometry of the KCdCl3 remains unaltered. The final product reflects only the intended reagents, not byproducts of the container.

Understanding Operational Characteristics

Uniform Thermal Conductivity

Beyond simple resistance, ceramic materials offer beneficial thermal properties. They facilitate the uniform heating of the powder inside, which is critical for consistent reaction rates throughout the sample.

Stability Across Temperature Ranges

While primarily selected for KCdCl3 calcination (typically several hundred degrees), these crucibles are often rated for temperatures exceeding 1000°C. This provides a significant safety margin against thermal shock or accidental overheating.

Making the Right Choice for Your Goal

When setting up your calcination process for KCdCl3, consider these factors:

- If your primary focus is Sample Purity: Rely on high-grade alumina to ensure absolutely no chemical leaching introduces impurities into your polycrystalline solid.

- If your primary focus is Process Safety: Utilize ceramic crucibles to ensure the vessel maintains its shape and structural integrity without deformation at peak temperatures.

By selecting the proper crucible, you transform the reaction vessel from a potential variable into a reliable constant.

Summary Table:

| Feature | Alumina/Ceramic Crucible Benefit | Impact on KCdCl3 Synthesis |

|---|---|---|

| Chemical Inertness | Non-reactive with reagents | Prevents leaching and ensures high sample purity |

| Thermal Stability | Resists deformation and decomposition | Maintains vessel integrity at high calcination temps |

| Thermal Conductivity | Facilitates uniform heat distribution | Ensures consistent reaction rates throughout the solid |

| Temperature Rating | Often rated >1000°C | Provides safety margin against thermal shock or overheating |

Elevate Your Materials Synthesis with KINTEK

Precision in high-temperature research begins with the right environment. KINTEK provides industry-leading lab solutions tailored for complex processes like perovskite calcination. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside premium ceramic consumables. Whether you need high-purity crucibles or fully customizable high-temperature furnaces, our team is dedicated to ensuring your polycrystalline solids meet the highest standards of chemical integrity.

Ready to optimize your heat treatment results? Contact KINTEK today for expert guidance and custom solutions!

Visual Guide

References

- Md. Sunjid Sorker, Md. Abdur Razzak Sarker. First-principles and experimental study to investigate structural, elastic, electronic, thermal, and optical properties of KCdCl3 metal halide perovskite crystals. DOI: 10.1063/5.0206191

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the role of a laboratory oven in the pre-treatment of Date Palm Stones? Enhance Torrefaction & Grinding Efficiency

- What properties make quartz tubes ideal for heat treatment processes? Unlock High-Temperature Purity and Stability

- What are the specific functions of the grinder and laboratory oven during sugarcane-based activated carbon preparation?

- Why is a platinum-gold alloy crucible utilized during the glass melting process? Achieve Unmatched Purity

- Why are high-purity alumina crucibles used for containing molten high-silicon steel? Ensure Purity & Thermal Stability

- What is the necessity of using a laboratory vacuum drying oven when processing Fe-N-C catalyst powders?

- What is the primary function of graphitized quartz glass tubes in the synthesis of Bi2Se3-Nd2Se3 alloys?

- What are some specialized applications of quartz tubes? Essential for High-Temperature and High-Purity Processes