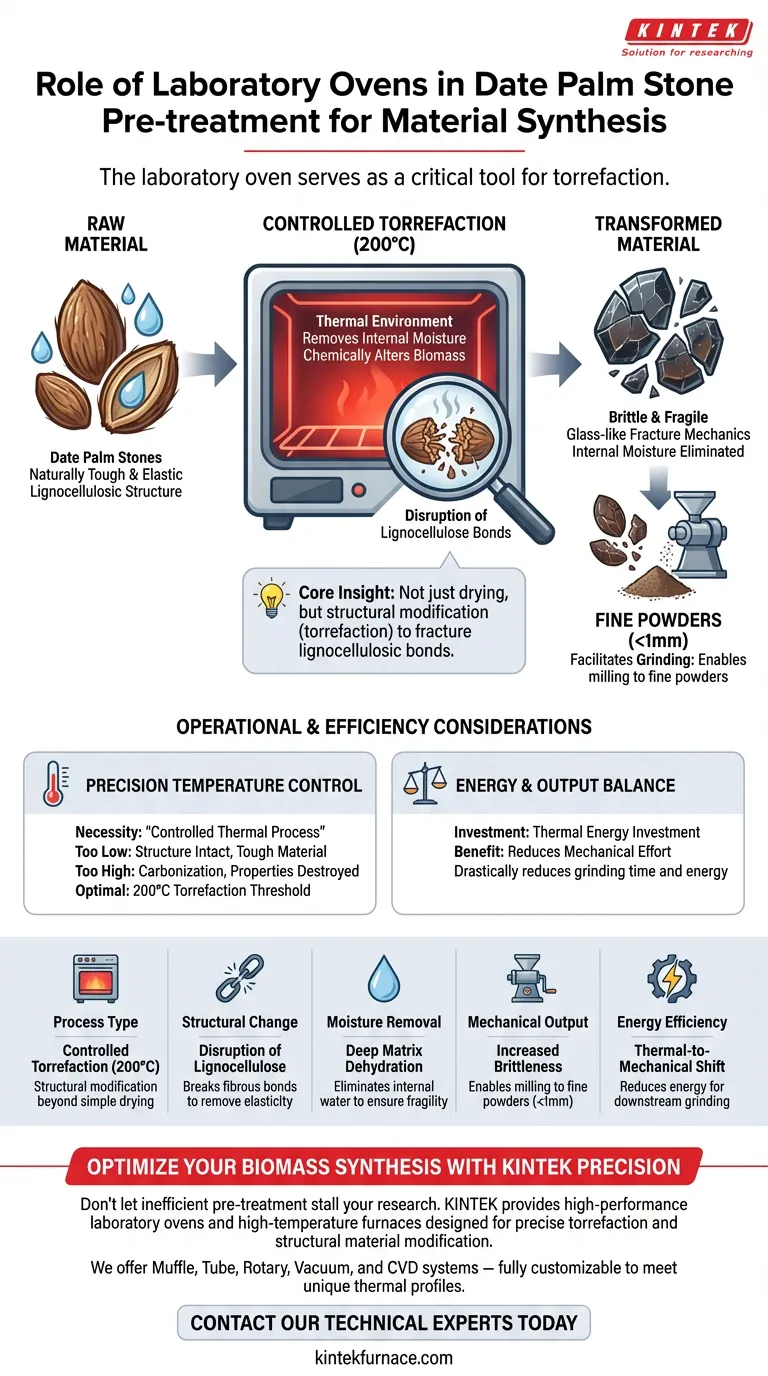

The laboratory oven serves as a critical tool for torrefaction in the pre-treatment of Date Palm Stones.

By subjecting the raw stones to a controlled thermal environment of approximately 200°C, the oven removes internal moisture and chemically alters the biomass. This process converts the naturally tough date stone into a brittle material, which is a prerequisite for effective mechanical grinding.

Core Insight While simple drying removes water, the laboratory oven in this context performs a structural modification known as torrefaction. This step is essential not just for dehydration, but for fracturing the material's lignocellulosic bonds to ensure it can be pulverized into fine powders later in the process.

The Mechanism of Thermal Pre-treatment

Controlled Torrefaction

The laboratory oven is not merely used for drying; it is utilized to induce torrefaction.

This is a mild form of pyrolysis carried out at specific temperatures, such as 200°C.

It creates a thermal environment that goes beyond surface evaporation to fundamentally alter the state of the raw material.

Disruption of Lignocellulose

Date Palm Stones are naturally composed of a rigid lignocellulosic structure.

The thermal treatment provided by the oven partially disrupts this structure.

By breaking down these internal fibrous bonds, the material loses its inherent elasticity and toughness.

Elimination of Internal Moisture

The process ensures the complete removal of internal moisture trapped deep within the stone's matrix.

This is distinct from surface drying, as it prevents the material from remaining pliable due to retained water content.

Impact on Downstream Processing

Increasing Brittleness

The primary outcome of this oven treatment is a significant increase in brittleness.

Raw date stones are hard and fibrous, making them difficult to crush.

Post-treatment, the stones become fragile and glass-like in their fracture mechanics.

Facilitating Grinding

This induced brittleness is the key enabler for the grinding stage.

Without thermal pre-treatment, grinding equipment would struggle to reduce the tough biomass efficiently.

The oven treatment allows the material to be easily milled into fine powders with particle sizes below 1mm.

Operational Considerations

The Necessity of Temperature Control

The process relies on a "controlled thermal process."

If the temperature is too low, the lignocellulosic structure will remain intact, resulting in a tough material that resists grinding.

If the temperature is too high (uncontrolled), you risk full carbonization or ashing, which destroys the desired organic synthesis properties.

Balancing Energy and Output

The use of the oven represents an energy investment to save mechanical effort later.

Investing thermal energy during pre-treatment drastically reduces the mechanical energy and time required to grind the stones to the necessary fineness.

Making the Right Choice for Your Goal

To maximize the efficiency of your material synthesis from Date Palm Stones, consider your specific processing requirements.

- If your primary focus is Ease of Comminution (Grinding): Ensure the oven reaches the full 200°C torrefaction threshold to maximize brittleness and minimize wear on grinding equipment.

- If your primary focus is Particle Size Uniformity: rigorous thermal pre-treatment is required to prevent fibrous strands from contaminating your <1mm powder fraction.

Thermal pre-treatment is not an optional drying step; it is a structural preparation that defines the quality of your final powder.

Summary Table:

| Feature | Role in Pre-treatment | Impact on Material Synthesis |

|---|---|---|

| Process Type | Controlled Torrefaction (200°C) | Structural modification beyond simple drying |

| Structural Change | Disruption of Lignocellulose | Breaks fibrous bonds to remove elasticity |

| Moisture Removal | Deep Matrix Dehydration | Eliminates internal water to ensure fragility |

| Mechanical Output | Increased Brittleness | Enables milling to fine powders (<1mm) |

| Energy Efficiency | Thermal-to-Mechanical Shift | Reduces energy required for downstream grinding |

Optimize Your Biomass Synthesis with KINTEK Precision

Don't let inefficient pre-treatment stall your research. KINTEK provides high-performance laboratory ovens and high-temperature furnaces designed for precise torrefaction and structural material modification.

Backed by expert R&D and world-class manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the unique thermal profiles required for date palm stone processing and material synthesis.

Ready to achieve superior particle uniformity and grinding efficiency? Contact our technical experts today to find the perfect thermal solution for your lab's unique needs!

Visual Guide

References

- Shaimaa K. Mohamed, Rasha M. Kamel. Efficient and low-cost mesoporous magnetic carbon composites derived from date palm stones for environmental remediation of hexavalent chromium. DOI: 10.1007/s10934-024-01611-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the advantages of using aluminum crucibles for siloxane research? Maximize Thermal Precision and Data Accuracy

- What environmental conditions do vacuum systems and quartz tubes provide? Optimize ZnS Nanobelt Synthesis

- What role does a high-purity Graphite Crucible play in super-gravity zinc recovery? Key Benefits & Functions

- What role do quartz tubes and vacuum sealing play in synthesis? Master High-Reactivity Compounds like U0.92Mn3Si2C

- How do alumina ceramic furnace tubes compare to other materials like quartz or silicon carbide? Choose the Best for Your High-Temp Needs

- What are the alternative names for a Laboratory Furnace? Find the Right High-Temperature Tool for Your Lab

- What is the necessity of using a laboratory vacuum drying oven when processing Fe-N-C catalyst powders?

- Alumina vs. Platinum Crucibles for Lithium Titanate (LTO) Synthesis: Which is Right for You?