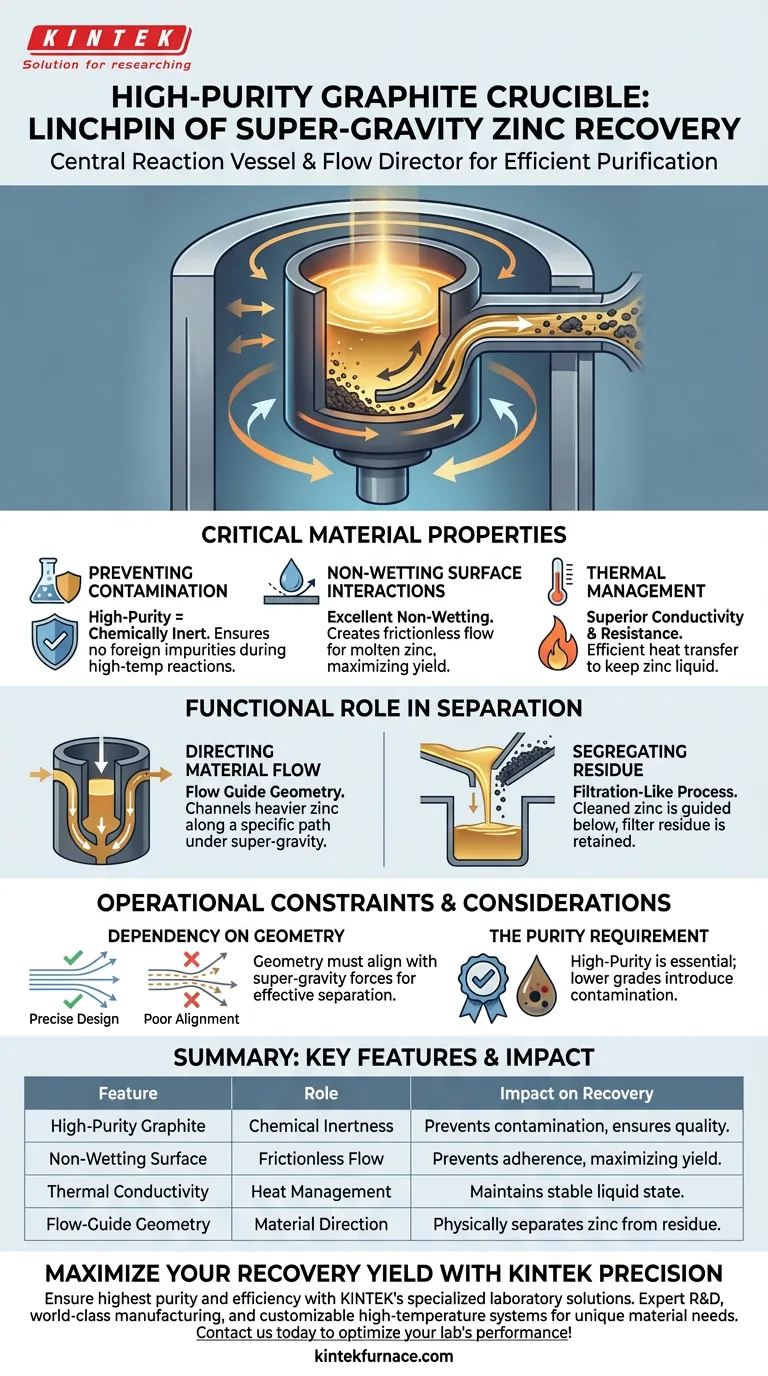

A high-purity Graphite Crucible acts as the central reaction vessel and flow director within a super-gravity separation apparatus. It serves a dual purpose: providing a contamination-free, high-temperature environment for molten zinc and physically guiding the separation of purified liquid from solid residue. Its specific structural design utilizes the forces of super-gravity to channel clean zinc into a collection zone while retaining impurities.

Core Takeaway The graphite crucible is not merely a container; it is an active mechanical component in the separation process. By combining non-wetting surface chemistry with a specific flow-guide geometry, it enables the physical segregation of zinc from residue without introducing new contaminants.

Critical Material Properties

Preventing Contamination

The "high-purity" designation of the graphite is essential, not optional. The crucible acts as a high-temperature reaction vessel that must remain chemically inert.

Because it does not react with the molten metal, it ensures that the zinc recovery process does not introduce foreign impurities, preserving the quality of the final output.

Non-Wetting Surface Interactions

One of the crucible's most vital characteristics is its excellent non-wetting property against metal liquids.

This means molten zinc does not adhere or "stick" to the graphite walls. This property creates a frictionless environment that allows the liquid to flow freely under super-gravity forces, maximizing recovery yield.

Thermal Management

The crucible possesses superior thermal conductivity and high-temperature resistance.

It facilitates efficient heat transfer to the zinc while maintaining structural integrity under the extreme thermal loads required to keep the metal in a liquid state.

Functional Role in Separation

Directing Material Flow

The crucible is engineered to function as a material flow guide. It is not a static bucket; its internal geometry is designed to interact with super-gravity.

As the apparatus spins, the crucible directs the movement of the molten material, channeling the heavier or more fluid components (the zinc) along a specific path.

Segregating Residue

The structural design facilitates a filtration-like process.

While the cleaned zinc liquid is guided to flow into a lower collection crucible, the filter residue is retained in the original position. This distinct physical separation allows for the easy removal of waste materials after the process is complete.

Operational Constraints and Considerations

Dependency on Structural Geometry

The efficiency of the separation relies heavily on the crucible's structural design.

If the geometry does not perfectly align with the super-gravity forces applied, the flow of zinc into the lower collection crucible may be compromised. The design must be precise to ensure the liquid flows down while the residue stays put.

The Purity Requirement

The system's success is contingent on the graphite being high-purity.

Using standard or lower-grade graphite would likely negate the non-wetting benefits and introduce contamination, defeating the purpose of the recovery apparatus.

Making the Right Choice for Your Goal

To maximize the efficiency of zinc recovery in a super-gravity apparatus, consider the following focus areas:

- If your primary focus is Purity: Ensure the graphite specification is certified high-purity to prevent chemical leaching and ensure the vessel remains inert during high-temperature reactions.

- If your primary focus is Yield: Prioritize the geometric design of the crucible to ensure it acts as an effective flow guide that fully exploits the non-wetting properties to channel every drop of zinc into the collection zone.

The Graphite Crucible is the linchpin of the system, transforming super-gravity forces into a precise mechanism for purification and separation.

Summary Table:

| Key Feature | Functional Role | Impact on Zinc Recovery |

|---|---|---|

| High-Purity Graphite | Chemical Inertness | Prevents contamination and ensures metal quality. |

| Non-Wetting Surface | Frictionless Flow | Prevents adherence, maximizing the recovery yield. |

| Thermal Conductivity | Heat Management | Maintains stable liquid state under extreme temperatures. |

| Flow-Guide Geometry | Material Direction | Physically separates molten zinc from filter residue. |

Maximize Your Recovery Yield with KINTEK Precision

Ensure the highest purity and efficiency in your metallurgical processes with KINTEK's specialized laboratory solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable high-temperature lab furnaces designed for your unique material needs.

Whether you are refining zinc or developing new alloys, our high-purity components and advanced thermal equipment provide the reliability your research demands. Contact us today to optimize your lab's performance!

Visual Guide

References

- S. J. Zhang, Zhancheng Guo. Purification and Recovery of Hot-Dip Galvanizing Slag via Supergravity-Induced Cake-Mode Filtration. DOI: 10.3390/met14010100

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the function of an in-situ heating holder in the study of Peierls transitions in NaRu2O4? Dynamic Lab Insights

- What information does laboratory XRD provide for Gallium Sulfide? Master GaS Single Crystal Characterization

- How does the impeller in a water circulating vacuum pump function to create a vacuum? Discover the Liquid Piston Mechanism

- What role do graphite molds play in graphite flake alignment? Engineered Precision for High Thermal Conductivity

- Why is a Boron Nitride coating applied to graphite crucibles for Mg3Sb2 alloys? Protect Purity and Tooling

- What functions does the hot pressing mold perform? Key Roles in Al3Ti/Al Composite Powder Metallurgy

- What is the technical value of using precise digital PID temperature controllers? Enhancing Ceramic Property Analysis

- How is the vacuuming operation performed with a water circulating vacuum pump? Master the Liquid Ring Technique