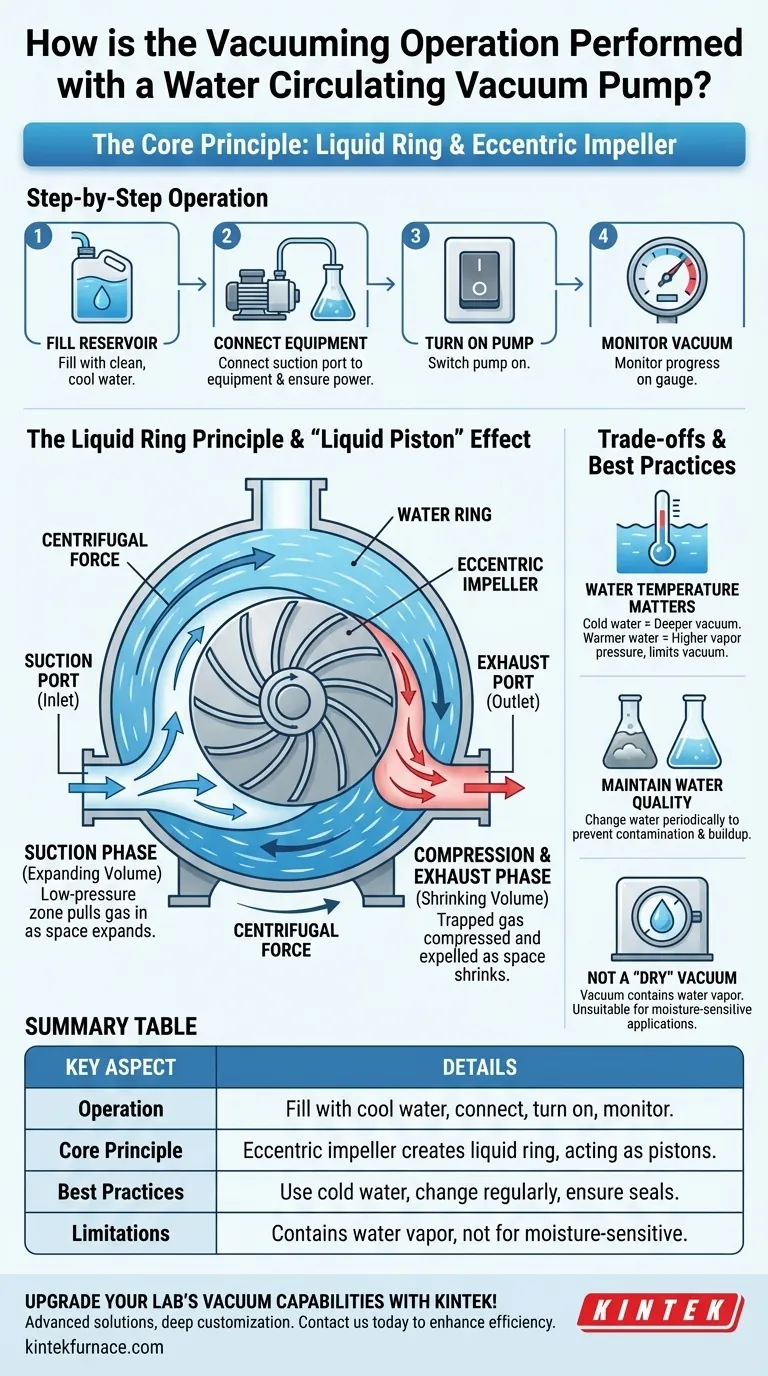

To perform a vacuum operation with a water circulating vacuum pump, you first fill its reservoir with clean, cool water. Next, you connect the pump's suction port to the equipment you need to evacuate, ensure the power is connected, and then simply turn the pump switch on. The internal mechanism will begin creating a vacuum, and you can monitor its progress on the attached vacuum gauge.

The core principle is not about water jetting or simple suction. Instead, a rotating, off-center impeller slings water against the pump's outer casing, forming a liquid ring. The expanding and contracting space between the impeller and this water ring acts as a series of "liquid pistons" that trap, compress, and expel air, thereby creating a vacuum.

The Principle of the Liquid Ring

To use this pump effectively, you must understand how it uses water to move air. It’s a clever mechanical process, not just a simple suction device.

The Role of Centrifugal Force

When you turn the pump on, an internal component called an impeller spins at high speed.

This rotation throws the water in the reservoir outwards due to centrifugal force, creating a stable, rotating ring of water that is pressed firmly against the inner wall of the cylindrical pump casing.

The Eccentric Impeller: The Key to Vacuum

The most critical design element is that the impeller is mounted eccentrically, or off-center, within the pump casing.

This means that as the impeller rotates, the space between the impeller's central hub and the inner surface of the water ring constantly changes.

The "Liquid Piston" in Action

This changing space creates a pumping action. Think of the space between two adjacent impeller blades as a small chamber.

- Suction Phase: As the blades rotate into the area where the chamber volume is expanding (the crescent-shaped space widens), a low-pressure zone is created. This pulls gas in from the suction port connected to your equipment.

- Compression & Exhaust Phase: As the blades continue to rotate into the area where the chamber volume is shrinking (the space narrows), the trapped gas is compressed. It is then pushed out through an exhaust port.

This cycle repeats with every rotation, continuously removing gas from your system and creating a reliable vacuum. The water both creates the seal and dissipates the heat of compression.

Understanding the Trade-offs and Best Practices

While robust, the performance of a water ring pump is directly tied to the condition of its working fluid—the water.

The Importance of Water Temperature

The ultimate vacuum a pump can achieve is limited by the vapor pressure of the water itself.

Warmer water has a higher vapor pressure, meaning it evaporates more easily. This water vapor acts as a gas that the pump cannot remove, setting a "floor" on how low the pressure can go. Using cold water results in a deeper, more effective vacuum.

Maintaining Water Quality

Over time, the water in the reservoir can become contaminated with solvents or chemicals pulled from your experiment. It can also become cloudy with mineral buildup.

Contaminated water can reduce pump efficiency and, in some cases, damage the internal components. It's good practice to periodically change the water with a fresh, clean supply.

Not a "Dry" Vacuum

Because the vacuum is created in direct contact with water, the resulting vacuum will always contain a small amount of water vapor. This makes it unsuitable for applications that are extremely sensitive to moisture.

Making the Right Choice for Your Goal

By understanding the underlying principle, you can optimize the pump's operation for your specific needs.

- If your primary focus is achieving the deepest vacuum: Always start with fresh, cold water and ensure all hose connections are perfectly sealed to prevent leaks.

- If your primary focus is long-term reliability: Regularly check and replace the reservoir water to prevent the buildup of contaminants or minerals that can degrade performance.

- If your primary focus is lab efficiency: Remember that many of these pumps have ports to simultaneously provide circulating cooling water for a condenser or other apparatus.

Mastering this tool comes from recognizing that you are controlling a dynamic mechanical system, not just flipping a switch.

Summary Table:

| Key Aspect | Details |

|---|---|

| Operation Steps | Fill reservoir with cool water, connect suction port, turn on pump, monitor vacuum gauge |

| Core Principle | Eccentric impeller creates liquid ring, acting as pistons to trap, compress, and expel air |

| Best Practices | Use cold water for deeper vacuum, change water regularly, ensure tight seals |

| Limitations | Not suitable for moisture-sensitive applications due to water vapor presence |

Upgrade your lab's vacuum capabilities with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your efficiency and results!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

People Also Ask

- Why is the precise regulation of oxygen ratios via mass flow controllers critical for MCTV catalyst yield?

- What are the key properties of alumina ceramic furnace tubes? Discover Their High-Temp and Chemical Resistance

- Why is a platinum-gold alloy crucible utilized during the glass melting process? Achieve Unmatched Purity

- What is the necessity of an observation window in a magnesium combustion chamber? Elevate Your Visual Data Analysis

- What is the primary function of a high-purity alumina crucible in PrVSb3 synthesis? Ensure Chemical Inertness & Purity

- Why use sealed quartz tubes & vacuum for Mg-Zn/Mg-Cd alloy prep? Ensure Compositional Purity

- What are the primary applications of alumina ceramic tubes? Ideal for High-Temp, Corrosive, and Insulating Needs

- What key functions do graphite molds serve during the hot press sintering? Enhance Ti/Al2O3 Composite Quality