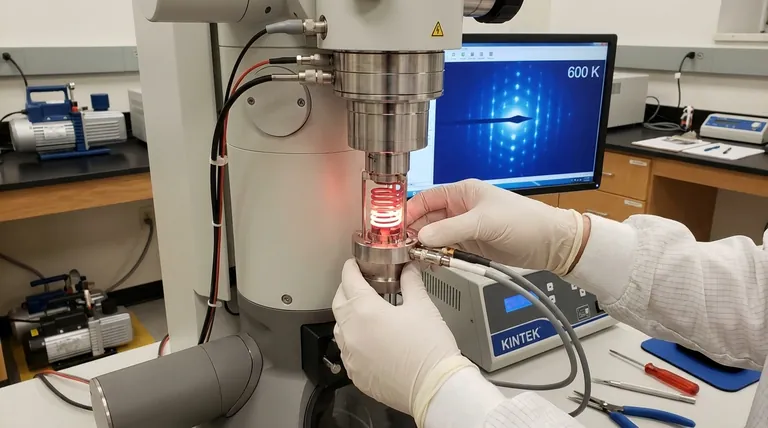

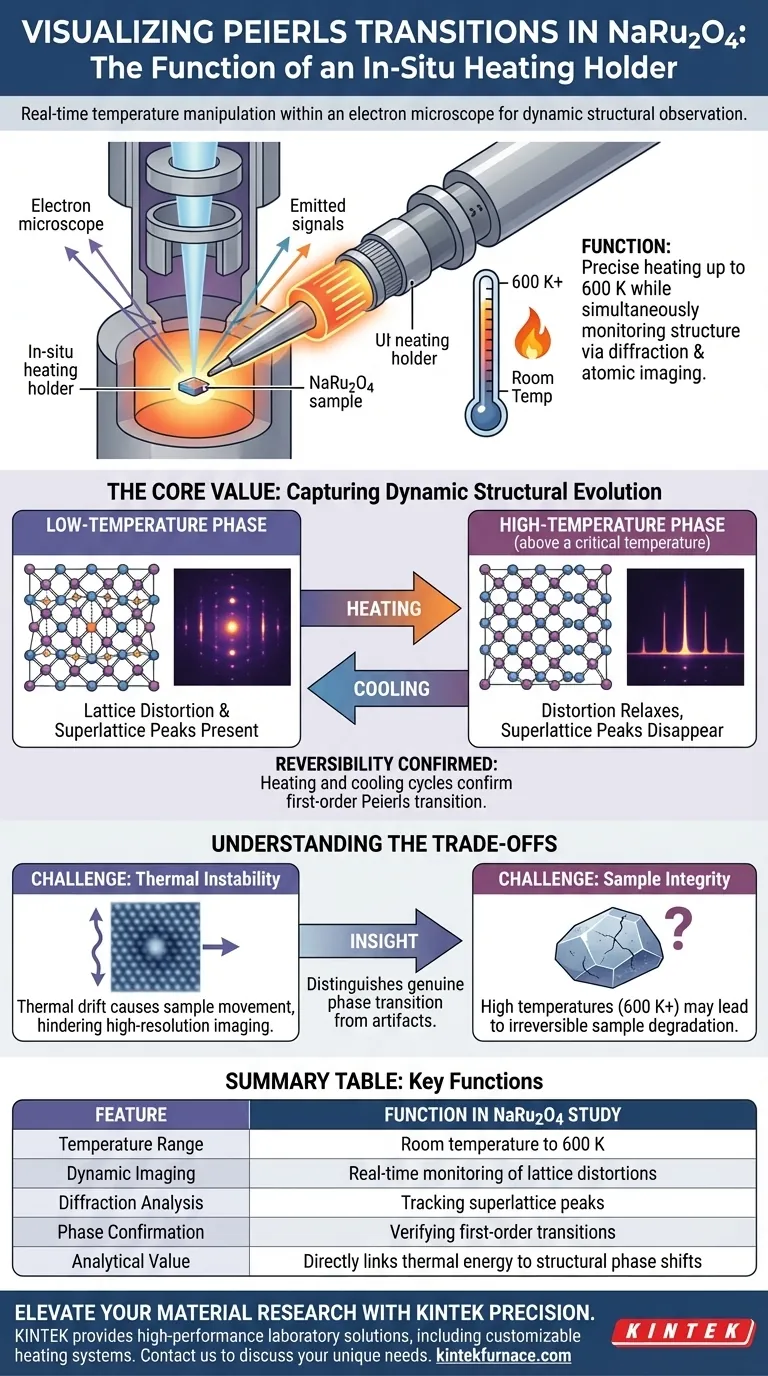

An in-situ heating holder is a critical instrument that allows for the precise, real-time manipulation of a sample's temperature within an electron microscope. In the context of NaRu2O4, its primary function is to heat the material from room temperature up to 600 K while researchers simultaneously monitor changes in the material's structure via diffraction patterns and atomic imaging.

The core value of this device lies in its ability to capture dynamic structural evolution. By observing the disappearance and reappearance of superlattice peaks during heating and cooling cycles, researchers can definitively confirm the nature of first-order Peierls transitions.

The Role of Real-Time Temperature Control

Enabling Dynamic Observation

Standard microscopy often analyzes samples at a static temperature. In-situ heating allows for the observation of changes as they happen.

Researchers can adjust the temperature inside the microscope column, moving the sample through critical thermal thresholds. This transforms the experiment from a static snapshot into a dynamic movie of the material's behavior.

Connecting Structure to Temperature

The holder typically covers a range from room temperature to over 600 K. This range is essential for NaRu2O4 because it encompasses the transition temperatures necessary to trigger phase changes.

By correlating specific temperatures with visual changes in the microscope, scientists can map the precise thermal conditions required for the Peierls transition.

visualizing the Peierls Transition

Tracking Lattice Distortion

A Peierls transition involves a specific type of structural change known as lattice distortion.

The in-situ holder allows researchers to directly see how the atomic arrangement shifts when thermal energy is added. This provides physical evidence of the distortion relaxing or disappearing as the temperature rises.

Monitoring Superlattice Peaks

The primary indicator of these transitions in diffraction patterns is the presence of superlattice peaks.

These peaks appear due to the periodic distortion of the crystal lattice in the low-temperature phase. The heating holder enables the direct observation of these peaks fading away as the material heats up.

Confirming First-Order Transitions

The capability to heat and cool the sample allows for the verification of reversibility.

When the sample is heated, the superlattice peaks disappear; when cooled, they reappear. This cycle confirms that the Peierls transition in NaRu2O4 is a first-order phase transition, characterized by distinct, observable structural states.

Understanding the Trade-offs

Thermal Instability

While in-situ heating provides valuable data, introducing heat into an electron microscope creates mechanical challenges.

Thermal drift is a common issue, where the expansion of holder components causes the sample to move physically. This can make capturing high-resolution atomic images difficult without advanced stabilization or correction.

Sample Integrity

Subjecting a sample to high temperatures (600 K+) inside a vacuum can sometimes lead to unintended degradation.

Researchers must distinguish between the genuine reversible phase transition and irreversible damage or decomposition of the NaRu2O4 crystal caused by thermal stress.

Making the Right Choice for Your Research

If you are investigating phase transitions in materials like NaRu2O4, the in-situ heating holder is an indispensable tool for validating structural theories.

- If your primary focus is characterizing the transition temperature: Use the holder to sweep temperatures slowly while monitoring diffraction patterns to pinpoint exactly when superlattice peaks vanish.

- If your primary focus is confirming the transition type: Focus on the reversibility of the process by performing multiple heating and cooling cycles to ensure the structural changes are consistent and not artifacts of damage.

In summary, the in-situ heating holder transforms the study of Peierls transitions from theoretical calculation to direct, observable verification.

Summary Table:

| Feature | Function in NaRu2O4 Study |

|---|---|

| Temperature Range | Room temperature to 600 K |

| Dynamic Imaging | Real-time monitoring of lattice distortions |

| Diffraction Analysis | Tracking the appearance/disappearance of superlattice peaks |

| Phase Confirmation | Verifying first-order transitions via heating/cooling cycles |

| Analytical Value | Directly links thermal energy to structural phase shifts |

Elevate Your Material Research with KINTEK Precision

Are you looking to validate complex structural theories or observe phase transitions with unmatched accuracy? KINTEK provides high-performance laboratory solutions designed for the most demanding research environments.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces—all fully customizable to meet your unique experimental needs. Whether you are studying NaRu2O4 or developing new advanced materials, our equipment ensures precise temperature control and reliability.

Ready to enhance your lab's capabilities? Contact us today to discuss how our custom heating solutions can drive your next breakthrough!

Visual Guide

References

- Anna Scheid, Peter A. van Aken. Direct Evidence of Anomalous Peierls Transition-Induced Charge Density Wave Order at Room Temperature in Metallic NaRu2O4. DOI: 10.1093/mam/ozae129

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the role of High-Strength Graphite Molds in Al-Ti-Zr sintering? Mastering Vacuum Hot Pressing Performance

- How does a high-precision heating stage contribute to the drying and crystallization of FAPbBr3 nanosheets?

- Why is a high-purity alumina crucible used for cored wire experiments? Ensure Zero-Contamination Heat Transfer

- What are the risks of using high-purity alumina crucibles for periodate decomposition? Avoid Crucial Data Errors

- What role does a corundum crucible play in the ceramic sintering process? Ensure High-Purity Material Integrity

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What are the technical considerations for selecting a stainless steel cylindrical vessel? Magnesium Test Chamber Guide

- What is the standard procedure for using a laboratory precision oven to determine the Total Solids (TS) of biomass?