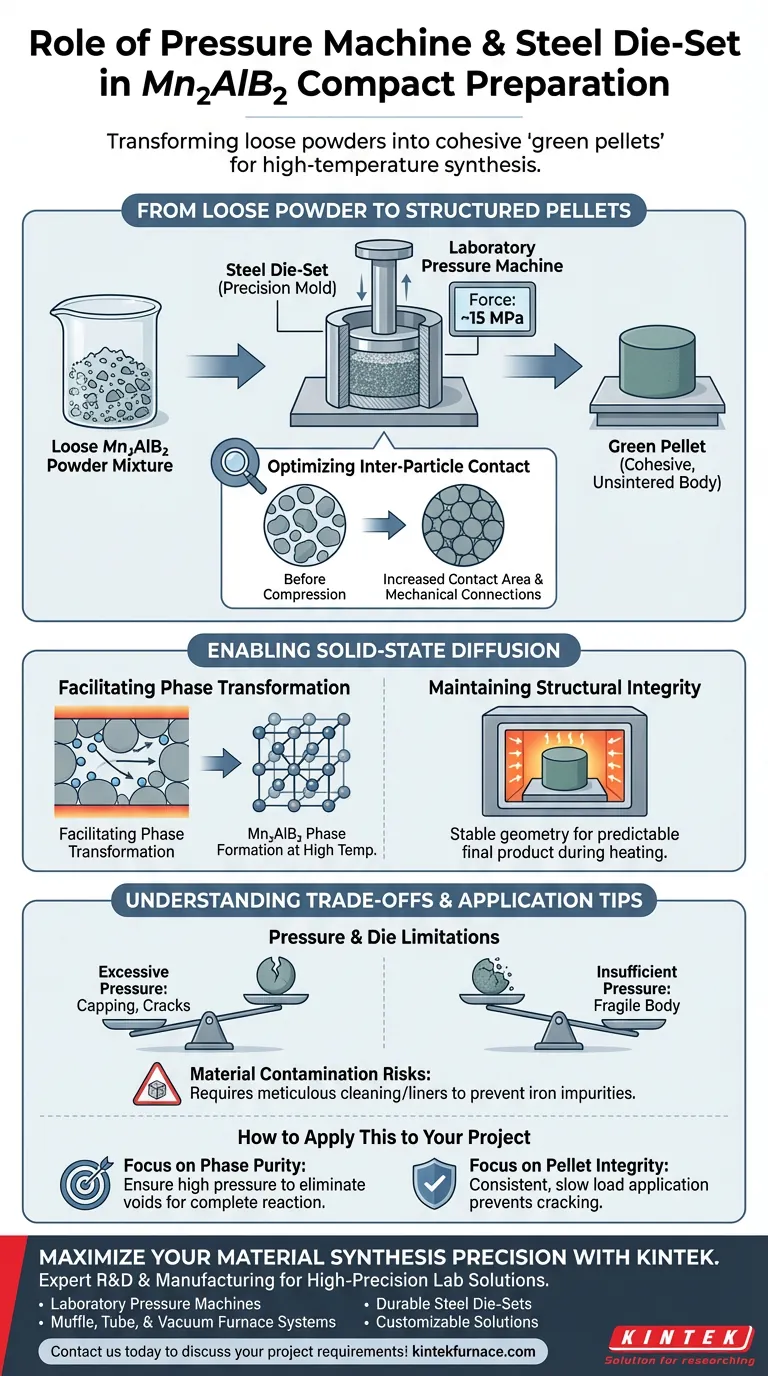

The laboratory pressure machine and steel die-set are the essential tools for transforming loose powders into a cohesive "green pellet." They work together to apply precise mechanical force—typically around 15 MPa—to $Mn_2AlB_2$ reactant powders. This process ensures the material has the structural integrity and particle-to-particle contact required for successful high-temperature synthesis.

By cold-pressing mixed powders into a dense compact, these tools create the physical foundation for solid-state diffusion. Without this initial compression, the subsequent phase transformations necessary to form $Mn_2AlB_2$ would be significantly less efficient.

From Loose Powder to Structured Pellets

The Mechanics of Cold-Pressing

A 1-inch steel die-set acts as the precision mold, containing the $Mn_2AlB_2$ powder mixture during the consolidation phase. The laboratory pressure machine then applies a specific, controlled load to these loose particles. The result is a green pellet, a solid but unsintered body that is robust enough to be handled and placed into a furnace.

Optimizing Inter-Particle Contact

Compression forces individual powder grains into closer proximity, which significantly increases the contact area between the different reactants. This increased surface contact is vital because it establishes the mechanical connections necessary for atoms to move between particles. Without this densification, the empty spaces (voids) between powders would act as thermal and chemical barriers.

Enabling Solid-State Diffusion

Facilitating Phase Transformation

The primary role of the compact is to set the stage for solid-state diffusion during subsequent high-temperature processing. As the heat increases, atoms migrate across the contact points established by the pressure machine and die-set. This atomic migration allows the elemental or precursor powders to chemically reorganize into the desired $Mn_2AlB_2$ phase.

Maintaining Structural Integrity

A well-pressed compact maintains its shape throughout the heating cycle, ensuring that the final product has a predictable geometry. The pressure applied by the machine ensures that the reactants stay in contact even as the material begins to undergo chemical changes. This stability is critical for achieving a uniform finished material.

Understanding the Trade-offs

Pressure and Die Limitations

While 15 MPa provides the necessary initial structure, applying excessive pressure can lead to "capping" or internal stress cracks within the pellet. Conversely, insufficient pressure results in a fragile pellet that may crumble before it ever reaches the furnace.

Material Contamination Risks

Using a steel die-set requires meticulous cleaning and often the use of a lubricant or liner to prevent the powder from sticking. If the die is not properly maintained, small amounts of iron or other contaminants could be introduced into the $Mn_2AlB_2$ mixture. These impurities can negatively impact the final properties of the synthesized material.

How to Apply This to Your Project

When preparing your $Mn_2AlB_2$ compacts, consider your specific experimental goals to determine how to best use your equipment.

- If your primary focus is phase purity: Ensure the pressure is high enough to eliminate large voids, as intimate contact is required for the solid-state reaction to reach completion.

- If your primary focus is pellet integrity: Focus on maintaining a consistent and slow application of the 15 MPa load to prevent the green body from cracking during decompression.

Mastering the initial compaction phase is the first critical step in ensuring the predictable and high-quality synthesis of MAB-phase materials.

Summary Table:

| Component | Primary Function | Impact on Mn2AlB2 Synthesis |

|---|---|---|

| Steel Die-Set | Precision Mold | Defines pellet geometry and contains powder during compression. |

| Pressure Machine | Mechanical Consolidation | Applies ~15 MPa to transform loose powder into a cohesive green body. |

| Cold-Pressing | Increasing Surface Contact | Enhances inter-particle contact area to facilitate atomic migration. |

| Green Pellet | Structural Foundation | Maintains integrity and shape for subsequent high-temperature furnace processing. |

Maximize Your Material Synthesis Precision

Successful Mn2AlB2 production starts with high-quality compaction. At KINTEK, we understand that the integrity of your green pellets is the foundation for advanced material research. Backed by expert R&D and manufacturing, KINTEK offers high-precision laboratory pressure machines and durable steel die-sets alongside our specialized Muffle, Tube, and Vacuum furnace systems.

Whether you need standard tools or fully customizable solutions for unique high-temperature synthesis, we provide the technical expertise to ensure uniform heating and structural stability for your materials.

Ready to elevate your lab's performance? Contact us today to discuss your project requirements!

Visual Guide

References

- Fatma Nur Tuzluca Yesilbag, Ahmad Hüseyin. The effect of Aluminum (Al) ratio on the synthesis of the laminated Mn2AlB2 MAB Phase. DOI: 10.18185/erzifbed.1514470

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the technical advantages of using ceramic crucibles for moxa floss pyrolysis? Ensure Precise Thermal Analysis

- Why is a heating device with magnetic stirring required for Y2O3-MgO precursors? Ensure Perfect Particle Coating

- What is the maximum vacuum capacity of the water circulating vacuum pump? Uncover Its Ideal Lab Applications

- What are the key properties of alumina ceramic tubes? Unlock High-Temp Performance for Your Lab

- What is the importance of using a Mass Flow Controller (MFC)? Enhance Molybdenum Phosphide (MoP) Synthesis Precision

- Why is a covered aluminum crucible necessary for g-C3N5 thermal polycondensation? Optimize Your Synthesis Atmosphere

- Why is a BN coating used in Mg3Sb2 melting? Essential Purity and Protection Guide

- What is the specific function of the water circulation cooler in zirconium sponge processing? Key for Purity & Safety