Ceramic crucibles act as a chemically neutral foundation for high-precision thermal analysis. In the context of moxa floss pyrolysis, their primary technical advantage is exceptional chemical stability at temperatures up to 900°C, ensuring the container does not react with the sample or its decomposition products. This inertness prevents mass artifacts, securing the validity of your thermogravimetric data.

The core value of ceramic crucibles is their ability to decouple the sample's behavior from the container's properties. By maintaining mass consistency and chemical inertness, they ensure that every data point on a thermogravimetric curve represents the moxa floss alone, free from external interference.

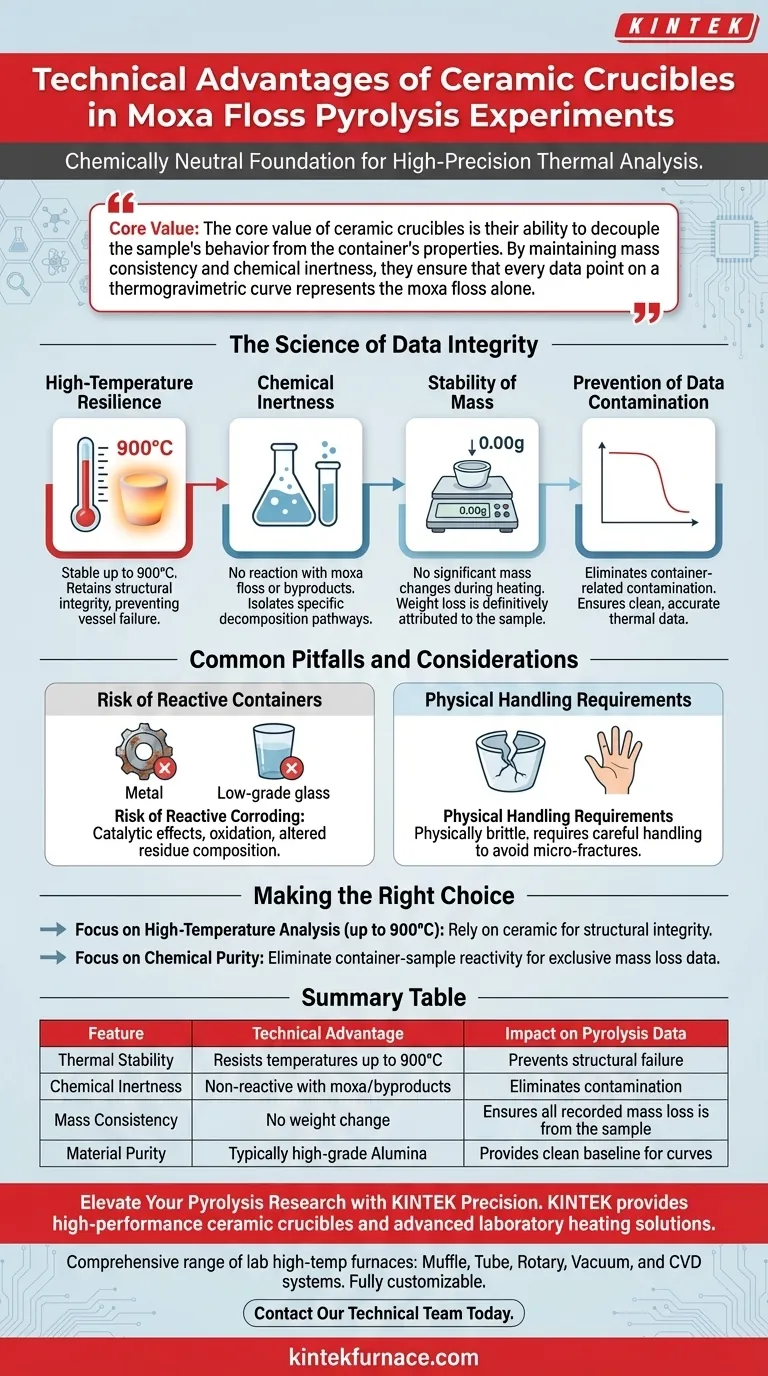

The Science of Data Integrity

To understand why ceramic crucibles are the standard for this application, we must look at the specific chemical and physical demands of pyrolysis.

High-Temperature Resilience

Moxa floss pyrolysis requires heating samples to significant temperatures to observe decomposition. Ceramic crucibles, typically composed of alumina, remain stable throughout experimental ranges reaching 900°C.

This thermal resistance ensures the vessel retains its structural integrity even at the upper limits of the experiment.

Chemical Inertness

A major challenge in pyrolysis is preventing the container from participating in the reaction. Ceramic crucibles exhibit no chemical reaction with moxa floss samples.

Furthermore, they remain non-reactive to the pyrolysis products (gases or residues) generated during heating. This neutrality is essential for isolating the specific decomposition pathways of the sample.

Stability of Mass

In thermogravimetric analysis, the primary metric is weight change. Ceramic crucibles do not exhibit significant mass changes when heated.

This stability means that any weight loss recorded by the instrument can be definitively attributed to the moxa floss, rather than the evaporation or oxidation of the crucible material itself.

Prevention of Data Contamination

By combining high-temperature resistance with chemical inertness, ceramic crucibles effectively prevent container-related contamination.

This ensures the purity of the experimental data, resulting in a clean thermogravimetric curve that accurately reflects the sample's thermal behavior without "ghost" peaks or skewed baselines.

Common Pitfalls and Considerations

While ceramic crucibles are technically superior for these experiments, understanding the alternative risks highlights their importance.

The Risk of Reactive Containers

Using containers made from less stable materials (such as certain metals or lower-grade glass) introduces the risk of catalytic effects or oxidation.

If a container reacts with the pyrolysis byproducts, it alters the chemical composition of the residue, rendering downstream chemical analysis invalid.

Physical Handling Requirements

While chemically robust, ceramic (alumina) materials are physically brittle compared to metal alternatives.

Operators must handle these crucibles with care to avoid micro-fractures, which—while not a chemical failure—can lead to mechanical failure or sample leakage during handling.

Making the Right Choice for Your Experiment

Selecting the correct sample container is a prerequisite for reproducible scientific results.

- If your primary focus is High-Temperature Analysis (up to 900°C): Rely on ceramic crucibles to maintain structural integrity where other materials might soften or degrade.

- If your primary focus is Chemical Purity: Use ceramic containers to eliminate the variable of container-sample reactivity, ensuring your mass loss data is exclusive to the moxa floss.

By standardizing on ceramic crucibles, you establish a baseline of reliability that allows you to focus on the science of the sample rather than the variables of the equipment.

Summary Table:

| Feature | Technical Advantage | Impact on Pyrolysis Data |

|---|---|---|

| Thermal Stability | Resists temperatures up to 900°C | Prevents structural failure during heating |

| Chemical Inertness | Non-reactive with moxa or byproducts | Eliminates contamination and catalytic artifacts |

| Mass Consistency | No weight change during heating | Ensures all recorded mass loss is from the sample |

| Material Purity | Typically high-grade Alumina | Provides a clean baseline for thermogravimetric curves |

Elevate Your Pyrolysis Research with KINTEK Precision

Don't let container-related artifacts compromise your experimental integrity. KINTEK provides high-performance ceramic crucibles and advanced laboratory heating solutions designed to deliver the most accurate thermogravimetric data.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are fully customizable to meet the unique demands of your material science research.

Ready to optimize your high-temperature analysis? Contact our technical team today to discuss how our specialized furnace systems and labware can bring unmatched precision to your laboratory.

Visual Guide

References

- Yukun Feng, Zhaoyi Zhuang. Combustion Characteristics of Moxa Floss Under Nitrogen Atmosphere. DOI: 10.3390/fuels6020048

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a high-purity alumina corundum crucible preferred for melting? Achieve High-Precision Research Integrity

- How does chemical compatibility affect the selection of alumina ceramic furnace tubes? Ensure Longevity and Purity

- Why is an additional large alumina outer crucible required? Ensure Safety and Equipment Longevity in Steel Research

- Why is the precision of a Mass Flow Controller (MFC) critical for ethanol vapor detection? Master Accurate Gas Mixing

- Why is a high-purity Alumina Crucible required during the annealing of MoS2? Ensure High-Temperature Material Purity

- What are the technical advantages of using ZrO2 crucibles? Elevate Smelting Accuracy with Zirconium Dioxide

- Why use a graphite box for WS2 sulfurization? Essential for High-Quality Thin Film Synthesis

- How does the gas control system regulate the plasma nitriding process? Master Your N2/H2 Mixture for Superior Surfaces