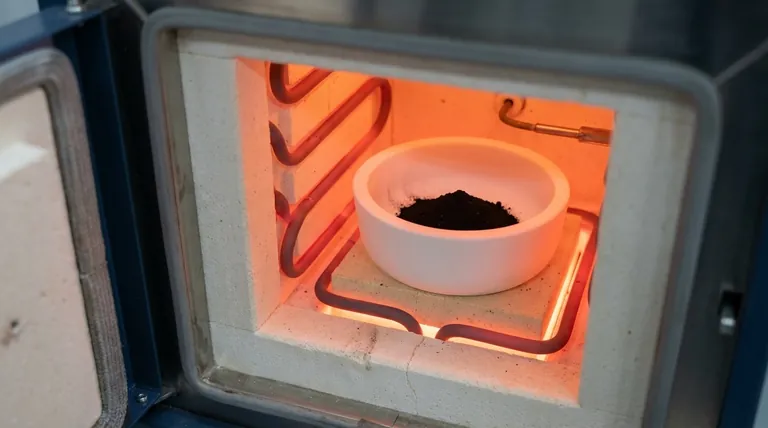

High-purity Alumina crucibles are required because they provide the necessary chemical stability and high-temperature resistance to protect Molybdenum Disulfide samples. During annealing processes that reach up to 900 °C, the crucible remains inert, preventing the container material from reacting with the sample or introducing metallic impurities.

The use of high-purity Alumina is critical for experimental validity. It ensures that any measured physical properties result strictly from the material's intrinsic defects rather than external contamination from the container.

The Critical Role of Chemical Stability

Withstanding Extreme Heat

The annealing process for Molybdenum Disulfide often involves temperatures reaching as high as 900 °C.

At these extremes, many standard laboratory containers would degrade or soften. High-purity Alumina retains its structural integrity, providing a safe environment for the thermal treatment.

Preventing Material Leaching

The primary function of the crucible is to act as a non-reactive barrier.

Because high-purity Alumina is chemically inert, it prevents reactions between the container walls and the Molybdenum Disulfide powder. This is vital to stop metallic impurities from the crucible explicitly leaching into the sample during heating.

Preserving Experimental Validity

Isolating Intrinsic Properties

Scientific analysis of annealed Molybdenum Disulfide often focuses on subtle characteristics, such as magnetic properties.

Researchers need to confirm that these properties originate from intrinsic defect generation within the material itself.

Eliminating False Positives

If a reactive crucible were used, impurities could enter the sample and display their own magnetic behaviors.

By using high-purity Alumina, researchers eliminate this variable. This guarantees that the experimental results reflect the true nature of the Molybdenum Disulfide, rather than the characteristics of a contaminated mixture.

Understanding the Risks of Alternative Materials

The Danger of Contamination

Using a crucible with lower purity or lower thermal resistance introduces a high risk of "phantom" results.

If the container reacts even slightly, it introduces foreign elements into the powder. This renders the data regarding intrinsic defects unusable, as it becomes impossible to distinguish between the sample's properties and the contaminants' properties.

Ensuring Accuracy in Your Analysis

If your primary focus is determining intrinsic magnetic properties:

- You must use high-purity Alumina to ensure the observed magnetism is not a result of metallic impurities leaching from the container.

If your primary focus is high-temperature safety:

- Reliance on Alumina is necessary to maintain containment integrity at annealing temperatures up to 900 °C.

Select the crucible material that guarantees the sample remains chemically isolated throughout the entire thermal process.

Summary Table:

| Feature | High-Purity Alumina Crucible Benefit |

|---|---|

| Thermal Resistance | Maintains structural integrity up to 900°C and above |

| Chemical Inertness | Prevents reactions between container walls and MoS2 samples |

| Purity Control | Eliminates metallic impurity leaching for accurate defect analysis |

| Experimental Validity | Ensures measured properties (e.g., magnetism) are intrinsic |

Elevate Your Materials Research with KINTEK

Don't let impurities compromise your experimental results. KINTEK provides high-purity Alumina crucibles and precision thermal equipment designed for the most demanding scientific applications. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique lab requirements.

Ready to ensure the integrity of your next annealing process?

Contact us today to find the perfect high-temperature solution for your lab!

References

- Chang-Soo Park, Deuk Young Kim. Strong Room-Temperature Ferromagnetism of MoS2 Compound Produced by Defect Generation. DOI: 10.3390/nano14040334

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does a high-precision vacuum pump reduce reaction temperatures in zinc extraction? Optimize Your Energy Efficiency

- How does the selection of a ceramic crucible contribute to the preparation of biomass carbon catalysts? Maximize Purity

- Why use graphite or quartz crucibles for liquid antimony-tellurium? Protect Your High-Temp Melt Integrity

- What are tube furnace tubes made of? Select the Right Material for Your Process

- Why is a precision laboratory hydraulic press required for sulfide-based batteries? Achieve Critical Ion Conductivity

- What role does a high-purity quartz tube play in flash Joule heating? Ensure Safety and Process Control

- How do quartz crucibles and quartz cover plates protect the substrate? Optimize TiO2 Nanowire Growth

- What is the purpose of using a PID controller to drive a heating furnace? Master Thermal Kinetics Precision