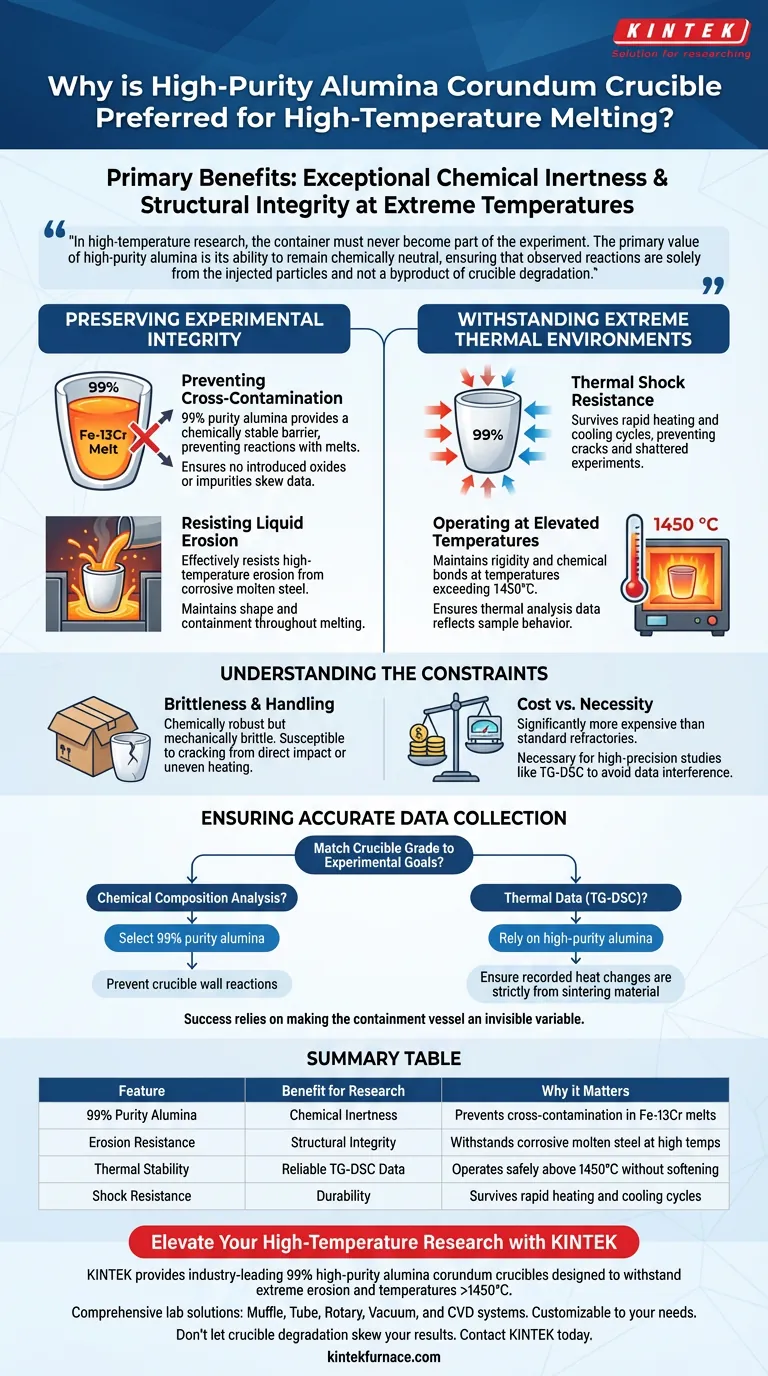

High-purity alumina corundum crucibles are preferred primarily for their exceptional chemical inertness and structural integrity at extreme temperatures. specifically, a 99% purity crucible effectively resists erosion from molten steel and prevents unwanted chemical reactions with specific alloys, such as Fe-13Cr melts. This ensures that the experimental environment remains uncontaminated, allowing for the isolation of specific variables in oxide particle injection studies.

In high-temperature research, the container must never become part of the experiment. The primary value of high-purity alumina is its ability to remain chemically neutral, ensuring that observed reactions are solely from the injected particles and not a byproduct of crucible degradation.

Preserving Experimental Integrity

Preventing Cross-Contamination

The most critical requirement in oxide particle injection studies is preventing the crucible material from leaching into the melt.

High-purity alumina (99%) provides a chemically stable barrier that prevents reactions with the Fe-13Cr melt.

Without this stability, the crucible itself could introduce oxides or other impurities, skewing the data regarding particle injection efficiency.

Resisting Liquid Erosion

Molten steel and other high-temperature liquids are highly corrosive and can physically wear down standard containment vessels.

Alumina corundum is chosen because it effectively resists this high-temperature erosion.

This durability ensures the crucible maintains its shape and containment properties throughout the duration of the melting process.

Withstanding Extreme Thermal Environments

Thermal Shock Resistance

Rapid temperature changes can cause inferior materials to crack or shatter, ruining an experiment in progress.

High-purity alumina offers excellent thermal shock resistance, allowing it to survive the rapid heating and cooling cycles often required in these studies.

Operating at Elevated Temperatures

Oxide particle studies often require temperatures exceeding 1450 °C.

At these ranges, lower-grade ceramics might soften or melt.

High-purity alumina maintains its rigidity and chemical bonds, ensuring that thermal analysis data reflects the sample's behavior, not the container's failure.

Understanding the Constraints

Brittleness and Handling

While alumina is chemically robust, it is mechanically brittle.

Despite its thermal shock resistance, it is generally susceptible to cracking if subjected to direct impact or uneven heating rates that exceed its specific limits.

Cost vs. Necessity

Using 99% purity corundum is significantly more expensive than standard refractory crucibles.

However, for high-precision studies like TG-DSC (Thermogravimetric-Differential Scanning Calorimetry), this cost is a necessary trade-offs.

Using a lower-grade crucible would introduce interference in heat change data, rendering precise thermodynamic readings useless.

Ensuring Accurate Data Collection

To ensure your study produces valid, reproducible results, you must match the crucible grade to your specific experimental goals.

- If your primary focus is Chemical Composition Analysis: Select 99% purity alumina to prevent the crucible wall from reacting with reactive melts like Fe-13Cr.

- If your primary focus is Thermal Data (TG-DSC): Rely on high-purity alumina to ensure recorded heat changes are generated strictly by the sintering material, not the container.

Success in high-temperature injection studies relies on making the containment vessel an invisible variable.

Summary Table:

| Feature | Benefit for Research | Why it Matters |

|---|---|---|

| 99% Purity Alumina | Chemical Inertness | Prevents cross-contamination in Fe-13Cr melts |

| Erosion Resistance | Structural Integrity | Withstands corrosive molten steel at high temps |

| Thermal Stability | Reliable TG-DSC Data | Operates safely above 1450°C without softening |

| Shock Resistance | Durability | Survives rapid heating and cooling cycles |

Elevate Your High-Temperature Research with KINTEK

Precision in oxide particle studies demands materials that never compromise your data. KINTEK provides industry-leading 99% high-purity alumina corundum crucibles designed to withstand extreme erosion and temperatures exceeding 1450°C.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique experimental needs.

Don't let crucible degradation skew your results. Contact KINTEK today to consult with our specialists and secure the high-purity equipment your lab deserves.

Visual Guide

References

- Alexandr Panichkin, Alexandr Arbuz. RESEARCH OF INJECTION METHODS FOR Y2O3 NANOPARTICLES INTO NICKEL- FREE STAINLESS STEEL DURING INDUCTION VACUUM REMELTING. DOI: 10.59957/jctm.v59.i1.2024.20

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the advantages of using an infrared thermograph over traditional thermocouples in Plasma Flash Sintering (PFS)?

- How does the purity of alumina ceramic tubes compare to quartz ceramic tubes? Discover Key Differences for Your Lab

- Why are alumina crucibles used for CoNb2O6 synthesis? Ensure High-Purity Ceramic Powder Production

- Why is a Zirconia (ZrO2) oxygen sensor used for CaO-Al2O3-VOx slag research? Achieve Precise Redox Control

- What is the primary function of the vacuum pump system in the magnesium powder evaporation process? Ensure High Purity & Efficiency

- What key functions do graphite molds perform in RuTi alloy sintering? Achieve High-Density Precision at 1000°C

- Why use high-purity quartz glass tubes for copper sulfide synthesis? Ensure Thermal Stability & Purity

- Why is an external cooling system vital for high-temperature furnace stability? Protect Your Research Integrity