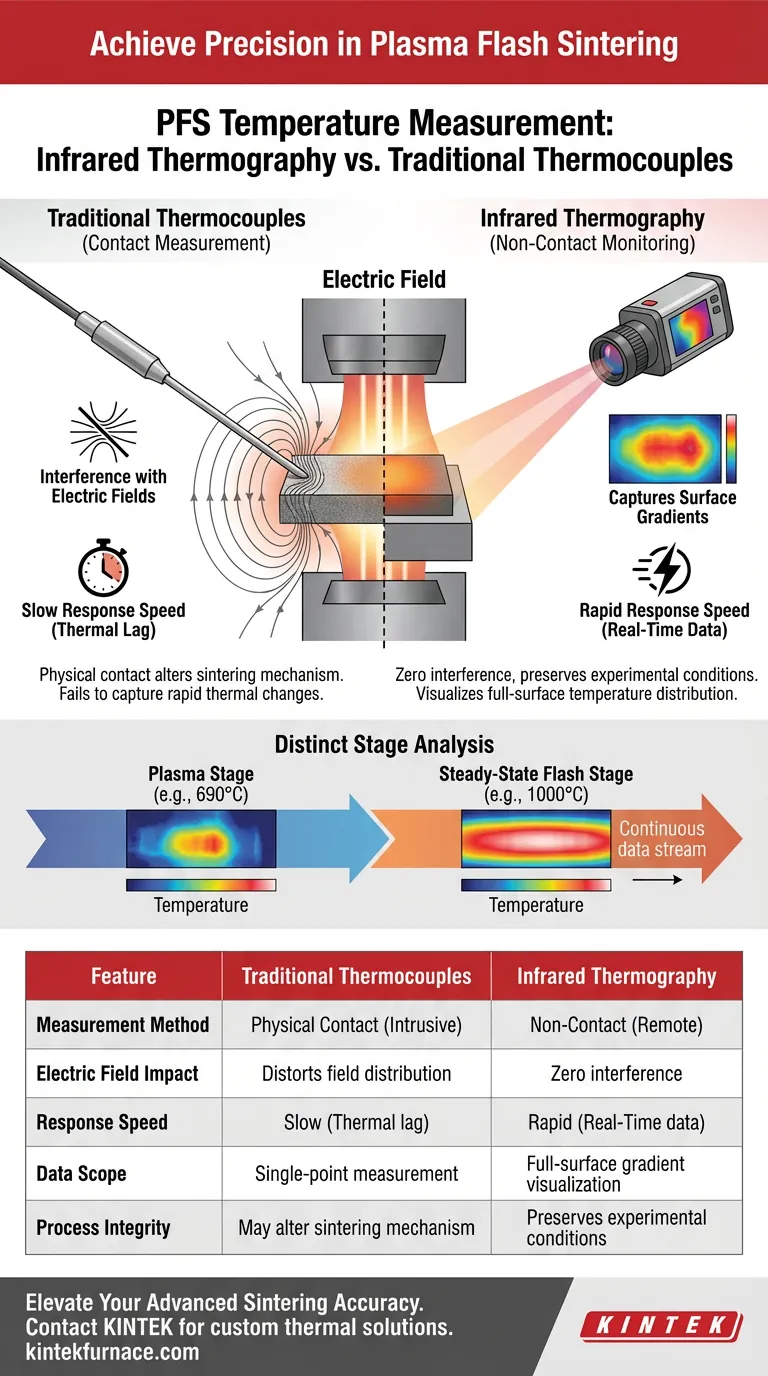

Infrared thermography provides a decisive advantage in Plasma Flash Sintering (PFS) by eliminating the physical contact that compromises traditional measurement methods. Unlike thermocouples, an infrared thermograph offers the rapid response speed necessary to capture real-time data without interfering with the sensitive electric field distribution required for the sintering process.

The core challenge in PFS is measuring temperature without altering the physics of the process. Infrared thermography solves this by enabling non-invasive, real-time observation of temperature gradients, ensuring data accuracy from the initial plasma discharge through the final flash stage.

The Limitations of Contact Measurement

To understand the value of infrared thermography, one must first recognize why traditional methods fail in this specific environment.

Interference with Electric Fields

Plasma Flash Sintering relies heavily on precise electrical discharge. Traditional contact thermocouples are intrusive. By physically touching the sample, they can interfere with the electric field distribution, potentially altering the sintering mechanism itself.

Inability to Track Heating Rates

PFS is characterized by extremely high heating rates. Thermocouples often lack the response speed required to keep up with these rapid thermal changes. This lag results in data that fails to reflect the true, instantaneous state of the material.

The Strategic Edge of Infrared Thermography

Switching to an infrared thermograph allows for a deeper understanding of the thermal mechanisms at play during PFS.

Non-Contact Real-Time Monitoring

The primary benefit is the ability to monitor the process remotely. This non-contact approach ensures that the electric field remains undisturbed, maintaining the integrity of the experimental conditions.

Capturing Surface Gradients

Unlike a thermocouple, which measures a single point, an infrared thermograph captures the entire surface. It precisely visualizes temperature distribution gradients, revealing how heat propagates across the sample geometry.

Distinct Stage Analysis

The tool is sensitive enough to distinguish between the critical phases of the process. It accurately captures thermal data during the plasma stage (e.g., 690°C) and the subsequent steady-state flash stage (e.g., 1000°C), providing a complete thermal history.

Common Pitfalls to Avoid

When selecting instrumentation for PFS, understanding the risks of the wrong tool is just as important as knowing the benefits of the right one.

The Illusion of Contact Accuracy

It is a common mistake to assume a physical sensor is always more accurate. In an electrically active environment like PFS, physical contact creates distortion. Relying on thermocouples here does not just yield slow data; it yields data from a process that has been fundamentally altered by the sensor's presence.

Overlooking Response Latency

Do not underestimate the speed of the "flash" event. Using sensors with high thermal mass or slow response times will smooth out the data peaks. This causes you to miss the critical transient spikes that define the flash sintering phenomenon.

Making the Right Choice for Your Goal

The choice between measurement tools defines the quality of your process insight.

- If your primary focus is process integrity: Choose infrared thermography to avoid interfering with the electric field distribution essential for sintering.

- If your primary focus is thermal mechanism analysis: Use infrared thermography to visualize real-time surface gradients and distinct heating stages.

By adopting non-contact monitoring, you move from estimating the process to accurately visualizing the thermal physics of Plasma Flash Sintering.

Summary Table:

| Feature | Traditional Thermocouples | Infrared Thermography |

|---|---|---|

| Measurement Method | Physical Contact (Intrusive) | Non-Contact (Remote) |

| Electric Field Impact | Distorts field distribution | Zero interference |

| Response Speed | Slow (Thermal lag) | Rapid (Real-time data) |

| Data Scope | Single-point measurement | Full-surface gradient visualization |

| Process Integrity | May alter sintering mechanism | Preserves experimental conditions |

Elevate Your Advanced Sintering Accuracy with KINTEK

Precision is the backbone of successful materials science. KINTEK provides the high-performance thermal solutions you need to master complex processes like Plasma Flash Sintering.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to your unique research specifications. Don't let measurement interference or equipment limitations compromise your data.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your custom furnace needs and see how our expertise can drive your innovation forward.

Visual Guide

References

- Eva Gil‐González, Luis A. Pérez‐Maqueda. Plasma‐flash sintering: Metastable phase stabilization and evidence of ionized species. DOI: 10.1111/jace.20105

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- What are the primary functions of multilayer fixtures within a lithium battery vacuum oven? Optimize Your Drying Process

- Why is a high vacuum pumping system necessary during the preparation of Sb2S3? Ensure High-Purity Semiconductor Films

- What functions do high-purity graphite crucibles serve in tantalum carbide synthesis? Essential Thermal & Chemical Roles

- What is the function of a vacuum system in PLD? Ensure High-Density, Pure Electrolyte Thin Films

- Why is modified PTFE used as a liner in high-pressure reactors for MoS2/C? Enhancing Purity and Yield.

- What is the purpose of vacuum sealing reactants in quartz tubes for Ni3In2Se2 synthesis? Achieve Stoichiometric Purity

- How does the purity of alumina ceramic tubes compare to quartz ceramic tubes? Discover Key Differences for Your Lab

- Why are high-purity alumina or ceramic boats required in a tube furnace? Protect Your Lab Equipment & Ensure Purity