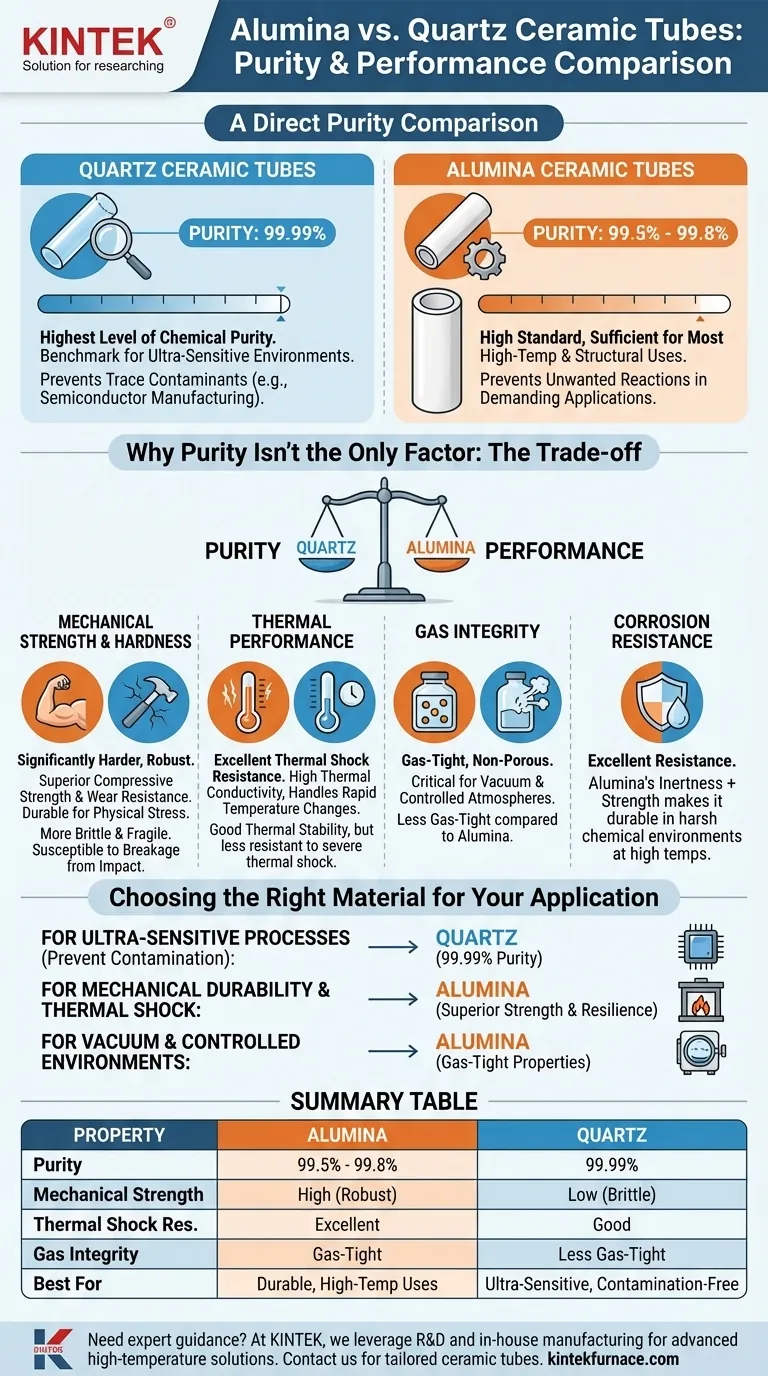

In a direct comparison, quartz ceramic tubes offer higher purity than alumina ceramic tubes. While high-purity alumina is exceptionally pure, typically ranging from 99.5% to 99.8%, quartz (fused silica) achieves an even higher purity level of 99.99%. This distinction is critical for applications where even trace contaminants are unacceptable.

While quartz provides the highest level of chemical purity, the choice between these materials is rarely about purity alone. The decision hinges on a crucial trade-off: selecting quartz for its inertness in ultra-sensitive environments versus choosing alumina for its superior mechanical strength and thermal shock resistance in more demanding applications.

A Direct Purity Comparison

Understanding the numbers is the first step. The subtle difference in purity percentages has significant implications for material selection in technical environments.

Quartz: The Purity Benchmark

With a purity of 99.99%, quartz is one of the purest materials available for industrial and laboratory use.

This exceptionally low level of impurities makes it the default choice for processes where preventing any form of chemical contamination is the absolute top priority, such as in semiconductor manufacturing or high-purity chemical analysis.

High-Purity Alumina

Alumina tubes are specified by their purity level, commonly ranging from 99.5% to 99.8%.

While technically less pure than quartz, this is still an incredibly high standard. For the vast majority of high-temperature furnace, insulation, and structural applications, this level of purity is more than sufficient and prevents unwanted reactions.

Why Purity Isn't the Only Factor

The decision between quartz and alumina extends beyond a simple purity contest. The mechanical and thermal properties of alumina often make it a more practical choice, even in high-stakes environments.

Mechanical Strength and Hardness

Alumina is significantly harder and more mechanically robust than quartz. It possesses superior compressive strength and excellent resistance to wear and abrasion.

This makes alumina the ideal choice for applications involving physical stress, frequent handling, or where durability is a primary concern. Quartz, by contrast, is more brittle and fragile.

Thermal Performance

Alumina exhibits excellent thermal shock resistance and high thermal conductivity. This allows it to withstand rapid temperature changes without cracking and helps distribute heat uniformly.

While quartz has excellent thermal stability, alumina's ability to handle thermal cycling is often a deciding factor for furnaces and processing tubes that are heated and cooled quickly.

Gas Integrity and Corrosion Resistance

High-purity alumina is sintered at very high temperatures, resulting in a dense, non-porous material. It is gas-tight, which is critical for maintaining a vacuum or a controlled, protective atmosphere.

Both materials have excellent corrosion resistance, but alumina's combination of chemical inertness and mechanical strength makes it exceptionally durable in harsh chemical environments at high temperatures.

Understanding the Trade-offs

Choosing the right material requires you to balance the need for absolute purity against the demands of physical performance.

The Cost of Absolute Purity

The primary reason to choose quartz is its near-perfect inertness. If your process cannot tolerate even parts-per-million levels of contamination from the tube itself, quartz is the only option.

However, this purity comes at the cost of mechanical fragility. Quartz tubes are more susceptible to breakage from physical impact or severe thermal shock compared to alumina.

The Workhorse Performance of Alumina

Alumina represents a powerful balance of properties. It offers very high purity combined with excellent strength, hardness, and thermal resilience.

Its versatility makes it the "workhorse" material for thousands of applications, from furnace process tubes and thermocouple insulators to laser components and electrical standoffs.

Choosing the Right Material for Your Application

Your specific goal should dictate your choice. Base your decision on the single most critical factor for your project's success.

- If your primary focus is preventing contamination in ultra-sensitive processes (like semiconductor manufacturing): Choose quartz for its unmatched 99.99% purity.

- If your primary focus is mechanical durability, thermal shock resistance, and general high-temperature use: Choose high-purity alumina for its superior strength and resilience.

- If your primary focus is creating a vacuum or a controlled gas environment at high temperature: Choose alumina for its gas-tight properties that are superior to quartz.

Understanding this balance between absolute purity and functional performance empowers you to select the optimal material for your specific technical challenge.

Summary Table:

| Property | Alumina Ceramic Tubes | Quartz Ceramic Tubes |

|---|---|---|

| Purity | 99.5% - 99.8% | 99.99% |

| Mechanical Strength | High (robust, wear-resistant) | Low (brittle, fragile) |

| Thermal Shock Resistance | Excellent | Good |

| Gas Integrity | Gas-tight | Less gas-tight |

| Best For | Durable, high-temperature uses | Ultra-sensitive, contamination-free processes |

Need expert guidance on selecting the right ceramic tube for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your lab's performance with tailored solutions!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment