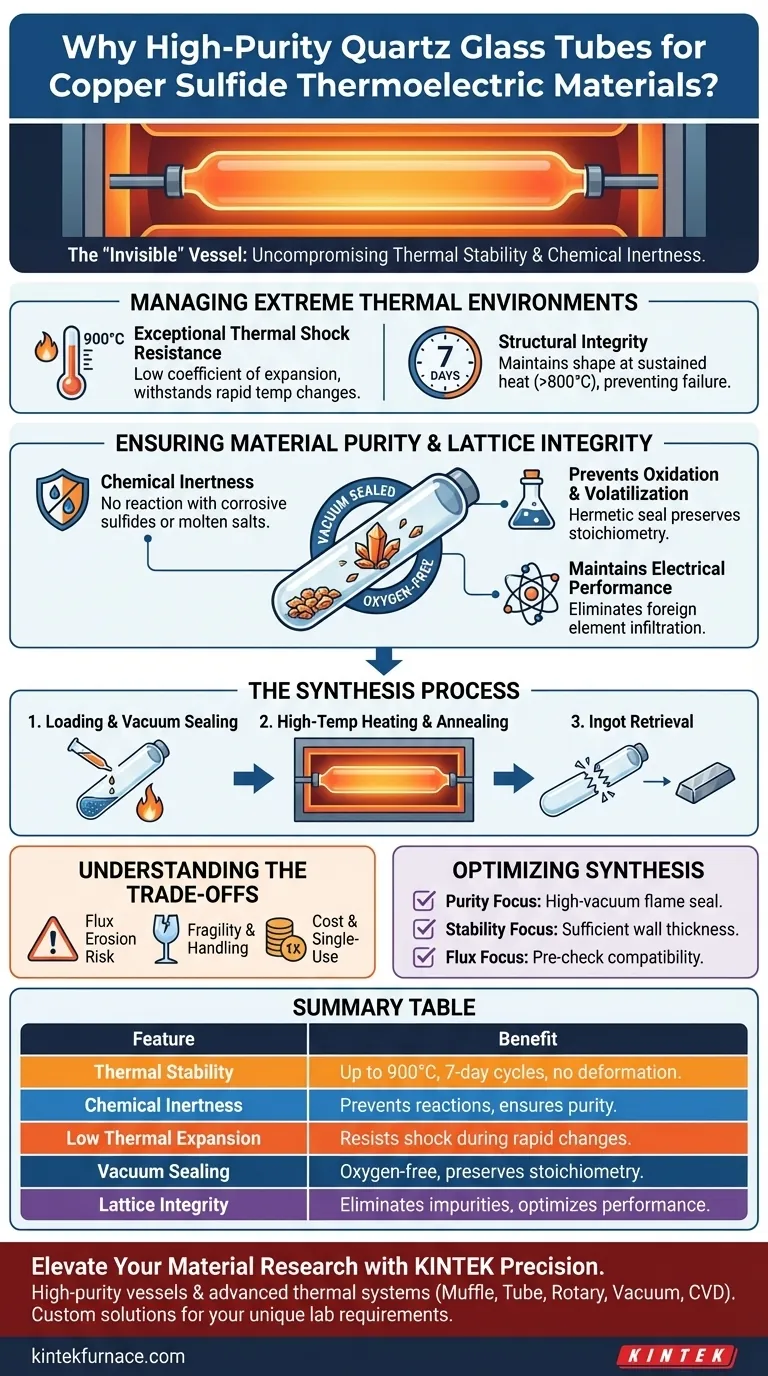

High-purity quartz glass tubes are the standard for synthesizing copper sulfide thermoelectric materials because they provide an uncompromising combination of thermal stability and chemical inertness. These tubes can withstand the extreme temperatures (up to 900°C) and prolonged seven-day annealing processes required for synthesis without cracking or deforming. Most importantly, quartz does not react with corrosive sulfides or molten salts, ensuring the final thermoelectric product reaches the high levels of purity necessary for efficient energy conversion.

The core value of high-purity quartz in this application is its ability to serve as a chemically "invisible" vessel. It maintains a vacuum-sealed, oxygen-free environment that prevents contamination and oxidation, which is critical for preserving the delicate electrical and thermal properties of copper sulfide.

Managing Extreme Thermal Environments

Exceptional Resistance to Thermal Shock

Copper sulfide synthesis involves high-temperature melting followed by extended annealing cycles. High-purity quartz possesses an extremely low coefficient of thermal expansion, allowing it to undergo rapid temperature changes without fracturing.

Structural Integrity at Sustained Temperatures

During the seven-day annealing process, the reaction vessel must remain structurally sound. Quartz maintains its shape and strength even when exposed to continuous heat exceeding 800°C–900°C, preventing vessel failure during long-term experiments.

Ensuring Material Purity and Lattice Integrity

Chemical Inertness Against Corrosive Sulfides

Sulfur vapor and molten salts used in these reactions are highly corrosive to many materials. High-purity quartz is chemically inert to these substances, ensuring that no container-derived impurities infiltrate the copper sulfide crystal lattice.

Prevention of Oxidation and Volatilization

Quartz tubes can be vacuum flame-sealed to create an absolute dry, oxygen-free micro-environment. This hermetic seal prevents the oxidation of copper salts and inhibits the volatilization of reagents, which is essential for maintaining the correct stoichiometry of the material.

Maintaining Electrical Performance

The efficiency of thermoelectric materials depends heavily on their "electrical purity." By preventing the introduction of foreign elements from the vessel wall, quartz glass ensures that the resulting material achieves the specific lattice integrity required for optimal performance.

Understanding the Trade-offs

The Risk of Flux Erosion

In specific synthesis techniques involving active fluxes, quartz can be susceptible to slow erosion. While usually chosen for its inertness, certain molten salt systems (like KOH or specific fluorides) may slowly react with the silica, potentially introducing silicon as an unintended dopant.

Fragility and Handling Requirements

Despite its thermal resilience, quartz remains a brittle material. It is susceptible to physical impact and must be handled with extreme care during the sealing and loading phases to avoid microscopic stress fractures.

Cost and Single-Use Limitations

High-purity quartz is significantly more expensive than standard laboratory glassware. Because these tubes are often flame-sealed and then broken to retrieve the synthesized ingot, the cost of consumables can become a significant factor in large-scale production.

Optimizing Your Synthesis Process

To achieve the best results when using quartz tubes for thermoelectric material preparation, consider your specific experimental goals.

- If your primary focus is maximum material purity: Use high-purity fused quartz and prioritize a high-vacuum flame seal to eliminate all traces of oxygen and moisture.

- If your primary focus is long-term thermal stability: Ensure the quartz tube has a sufficient wall thickness to withstand internal pressure and sustained heat during the seven-day annealing window.

- If your primary focus is preventing contamination from fluxes: Pre-check the compatibility of your molten salt system with silica to ensure no erosion occurs at your target operating temperature.

Selecting the right grade of high-purity quartz is ultimately an investment in the reliability and performance of the resulting thermoelectric material.

Summary Table:

| Feature | Benefit for Copper Sulfide Synthesis |

|---|---|

| Thermal Stability | Withstands temperatures up to 900°C and 7-day annealing cycles without deformation. |

| Chemical Inertness | Prevents reactions with corrosive sulfides and molten salts, ensuring material purity. |

| Low Thermal Expansion | Excellent resistance to thermal shock during rapid temperature changes and melting. |

| Vacuum Sealing | Enables oxygen-free, hermetic environments to prevent oxidation and maintain stoichiometry. |

| Lattice Integrity | Eliminates foreign element infiltration to preserve electrical and thermal properties. |

Elevate Your Material Research with KINTEK Precision

High-performance thermoelectric materials demand uncompromising environments. At KINTEK, we understand that your results are only as good as your tools. Backed by expert R&D and manufacturing, we provide high-purity quartz vessels and advanced thermal systems designed to meet the rigorous demands of material synthesis.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our equipment is fully customizable to your unique lab requirements. Ensure the purity, stability, and integrity of your next breakthrough—contact our technical experts today to find your perfect solution.

Visual Guide

References

- Yixin Zhang, Zhen‐Hua Ge. Synergistically optimized electron and phonon transport in high-performance copper sulfides thermoelectric materials via one-pot modulation. DOI: 10.1038/s41467-024-47148-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does the hardness of alumina ceramics compare to other materials? Discover Its Superior Wear Resistance

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- Why are quartz tubes suitable for material research applications? Ensure Purity and Precision in High-Temp Experiments

- What role do contact thermocouples play during the high-temperature annealing experiments of oriented silicon steel?

- What role does a rotary evaporator serve in the processing of banana inflorescence extracts? Maximize Bioactive Recovery

- Why is vacuum sealing in high-purity quartz tubes necessary for the synthesis of FexTaSe2? Master Crystal Growth

- What are the considerations for using vacuum-sealed quartz tubes for Ti-xCr-2Ge alloys? Ensure Peak Alloy Performance

- How does the design of a graphite box optimize the sulfurization of Sb thin films? Key Insights for Film Uniformity