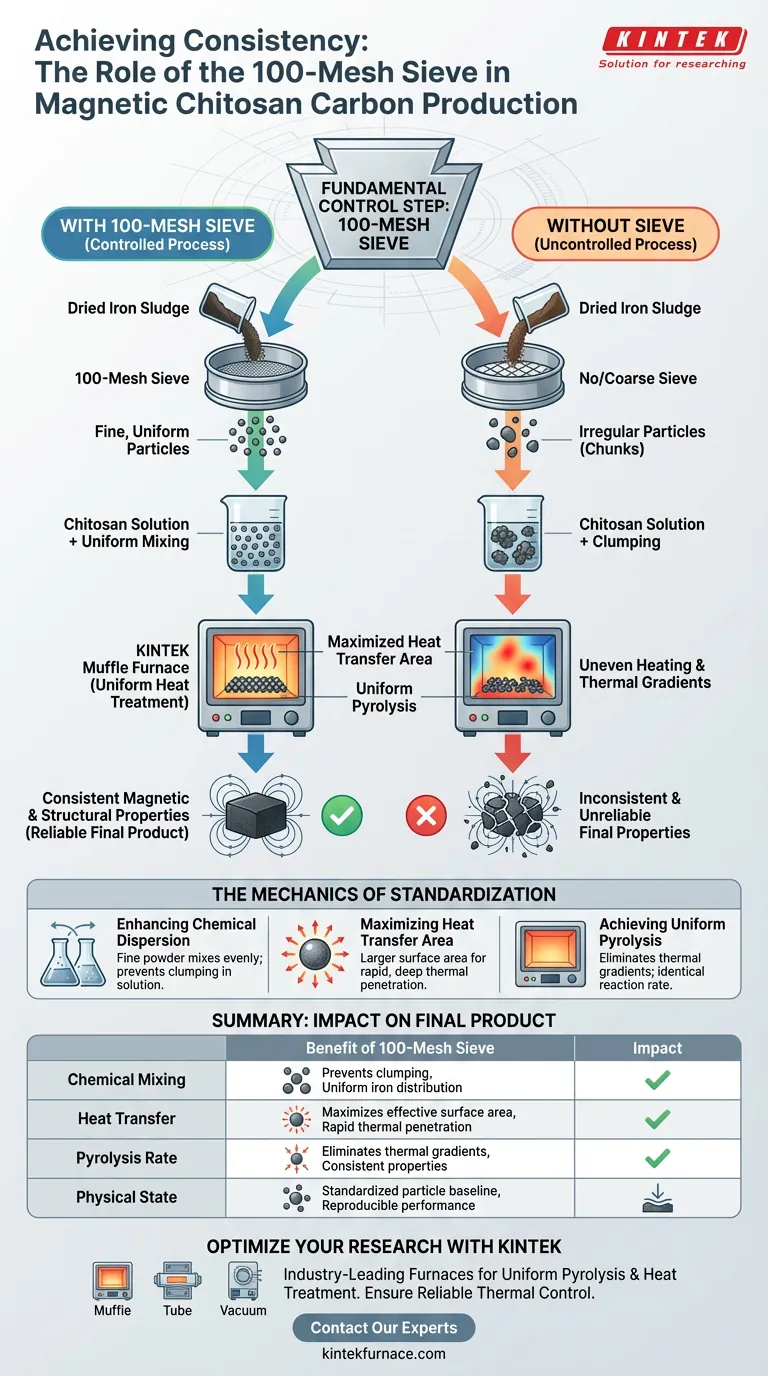

The use of a 100-mesh sieve is the fundamental control step that establishes the physical baseline for high-quality magnetic chitosan carbon. By processing dried iron sludge through this specific mesh, you ensure a fine, uniform particle size that is essential for both effective chemical mixing and thermodynamic stability during heat treatment.

Standardizing particle size is not merely a preparatory step; it is a critical process variable that maximizes the heat transfer area and ensures uniform dispersion. This directly results in a pyrolysis process where every particle reacts under identical conditions, securing consistent magnetic and structural properties.

The Mechanics of Particle Standardization

Enhancing Chemical Dispersion

Before heat is applied, the raw materials must be chemically integrated. Passing the dried iron sludge through a 100-mesh sieve creates a fine powder that disperses uniformly within the chitosan solution.

This prevents clumping and ensures that the iron component is evenly distributed throughout the chitosan matrix prior to solidification.

Maximizing Heat Transfer Area

The consistency of the final product relies heavily on how the material absorbs thermal energy. Finer, standardized particles provide a significantly larger effective heat transfer area.

This increased surface area allows the heat from the furnace to penetrate the material more efficiently and rapidly.

Achieving Uniform Pyrolysis

Inside the muffle furnace, uneven heating is the primary cause of variable product quality. The sieving process guarantees that the precursor is heated evenly throughout the sample.

This prevents thermal gradients, ensuring that the chemical transformation (pyrolysis) occurs at the same rate across the entire batch.

The Consequences of Irregularity

Inconsistent Final Properties

The primary trade-off of skipping or rushing the sieving process is a loss of predictability. Without a standardized particle size, the precursor will suffer from uneven thermal distribution.

This directly leads to fluctuations in the magnetic and structural properties of the final magnetic chitosan carbon, rendering the material unreliable for precise applications.

Ensuring Process Reliability

If your primary focus is Structural Homogeneity:

- Strictly adhere to the 100-mesh standard to ensure the iron sludge mixes seamlessly into the chitosan solution without agglomeration.

If your primary focus is Magnetic Performance:

- Prioritize particle uniformity to guarantee even heat distribution during pyrolysis, which is required to lock in consistent magnetic traits.

Control the particle size, and you control the consistency of your final material.

Summary Table:

| Process Variable | Benefit of 100-Mesh Sieve | Impact on Final Product |

|---|---|---|

| Chemical Mixing | Prevents clumping in chitosan solution | Uniform iron distribution within matrix |

| Heat Transfer | Maximizes effective surface area | Rapid, deep thermal penetration |

| Pyrolysis Rate | Eliminates thermal gradients | Consistent structural and magnetic properties |

| Physical State | Standardized particle baseline | Reproducible material performance |

Optimize Your Materials Research with KINTEK

Achieving consistent magnetic chitosan carbon requires more than just precision sieving; it demands the reliable thermal control of high-performance lab equipment.

KINTEK provides industry-leading Muffle, Tube, and Vacuum furnaces specifically engineered for uniform pyrolysis and heat treatment. Whether you are conducting fundamental R&D or advanced manufacturing, our customizable systems ensure your standardized precursors undergo the exact thermal transformation needed for superior performance.

Ready to elevate your lab's precision? Contact our experts today to discuss our range of customizable high-temperature solutions.

Visual Guide

References

- Huiping Zeng, Dong Li. Facile Preparation of Magnetic Chitosan Carbon Based on Recycling of Iron Sludge for Sb(III) Removal. DOI: 10.3390/su16072788

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis