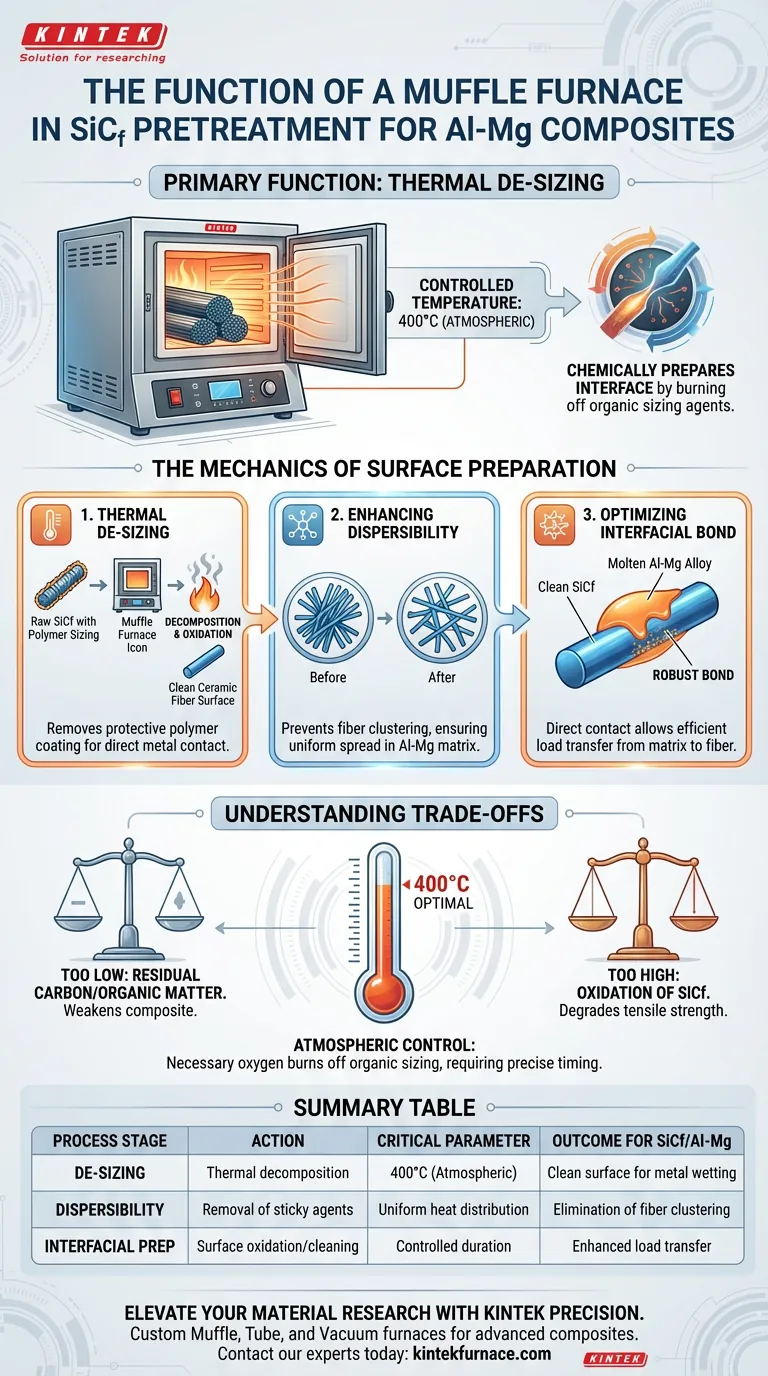

The primary function of a muffle furnace in this context is thermal de-sizing. Specifically, it subjects Silicon Carbide fibers (SiCf) to a controlled temperature of 400°C in an atmospheric environment to essentially burn off organic sizing agents found on the fiber surface.

The muffle furnace does not simply heat the material; it chemically prepares the interface. By eliminating organic coatings through thermal decomposition, it exposes the raw fiber surface, which is a prerequisite for creating a robust bond with the Aluminum-Magnesium matrix.

The Mechanics of Surface Preparation

Thermal De-sizing

Raw Silicon Carbide fibers typically arrive with a protective polymer coating known as "sizing." This coating must be removed before the fibers can be used in a metal matrix.

The muffle furnace provides a stable, atmospheric thermal environment that oxidizes these organic agents. At 400°C, the sizing agents decompose and burn away, leaving the underlying ceramic fiber clean.

Enhancing Dispersibility

Sizing agents often cause fibers to cluster or stick together. By removing these agents, the muffle furnace treatment significantly improves the dispersibility of the fibers.

This ensures that when the fibers are introduced to the Al-Mg matrix, they spread uniformly rather than forming weak, clumped aggregates.

Optimizing the Interfacial Bond

The critical "deep need" addressed by this process is the integrity of the fiber-matrix interface. If sizing agents remain, they act as a contaminant between the ceramic fiber and the metal.

By exposing the clean SiC surface, the molten Aluminum-Magnesium alloy can wet the fiber directly. This direct contact is essential for transferring mechanical loads from the matrix to the strong fibers.

Understanding the Trade-offs

Temperature Sensitivity

While the goal is to remove impurities, the temperature must be strictly controlled at 400°C.

If the temperature is too low, residual carbon or organic matter may remain, weakening the composite. Conversely, if the temperature exceeds the optimal range, you risk oxidizing the Silicon Carbide fiber itself, which degrades its intrinsic tensile strength.

Atmospheric Control

Unlike vacuum furnaces used for other treatments, this process relies on an atmospheric environment to facilitate oxidation. The presence of oxygen is necessary to burn off the organic sizing, but it also necessitates precise timing to prevent damage to the fiber substrate.

Making the Right Choice for Your Goal

To maximize the performance of your Al-Mg composite, apply the pretreatment based on your specific priorities:

- If your primary focus is Mechanical Strength: Ensure the furnace maintains a uniform 400°C to achieve complete de-sizing, as any residue will act as a crack initiation site.

- If your primary focus is Process Consistency: Standardize the duration of the roast to balance the removal of sizing against the risk of fiber surface oxidation.

The muffle furnace is the gatekeeper of composite quality, transforming raw, coated fibers into a reinforcement material capable of bonding with metal.

Summary Table:

| Process Stage | Action | Critical Parameter | Outcome for SiCf/Al-Mg |

|---|---|---|---|

| De-sizing | Thermal decomposition of organic coatings | 400°C (Atmospheric) | Clean fiber surface for direct metal wetting |

| Dispersibility | Removal of sticky polymer agents | Uniform heat distribution | Elimination of fiber clustering and aggregates |

| Interfacial Prep | Surface oxidation/cleaning | Controlled duration | Enhanced load transfer between fiber and matrix |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect 400°C thermal environment for Silicon Carbide fiber pretreatment requires absolute temperature uniformity and reliable atmospheric control. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnaces designed to meet the rigorous demands of advanced composite manufacturing.

Our expert R&D and manufacturing teams specialize in delivering customizable high-temp solutions tailored to your unique laboratory needs. Whether you are optimizing SiCf/Al-Mg interfaces or developing new metal matrix composites, KINTEK ensures your process consistency and mechanical strength.

Ready to refine your thermal processes? Contact our experts today to find your custom solution!

Visual Guide

References

- Guanzhang Lin, Zhaozhao Lv. Strengthening Mechanism and Damping Properties of SiCf/Al-Mg Composites Prepared by Combining Colloidal Dispersion with a Squeeze Melt Infiltration Process. DOI: 10.3390/ma17071600

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the specific technical functions of hydrothermal autoclaves and muffle furnaces in catalyst preparation?

- What are the primary uses of muffle furnaces in the pharmaceutical industry? Ensure Drug Purity and Stability

- What are the potential disadvantages of muffle furnaces? Key Trade-offs for Lab Precision

- What are the primary uses of a muffle furnace? Achieve Precise High-Temperature Processing

- What are the characteristics and applications of muffle furnaces? Achieve Pure, High-Temperature Heating for Your Lab

- What factors should be considered when purchasing a box type electric furnace? Ensure Optimal Performance for Your Lab

- What materials are recommended for muffle furnace construction? Optimize for High-Temp Performance and Safety

- What critical support does an industrial muffle furnace provide in mineral dielectric evolution? Real-Time Insights