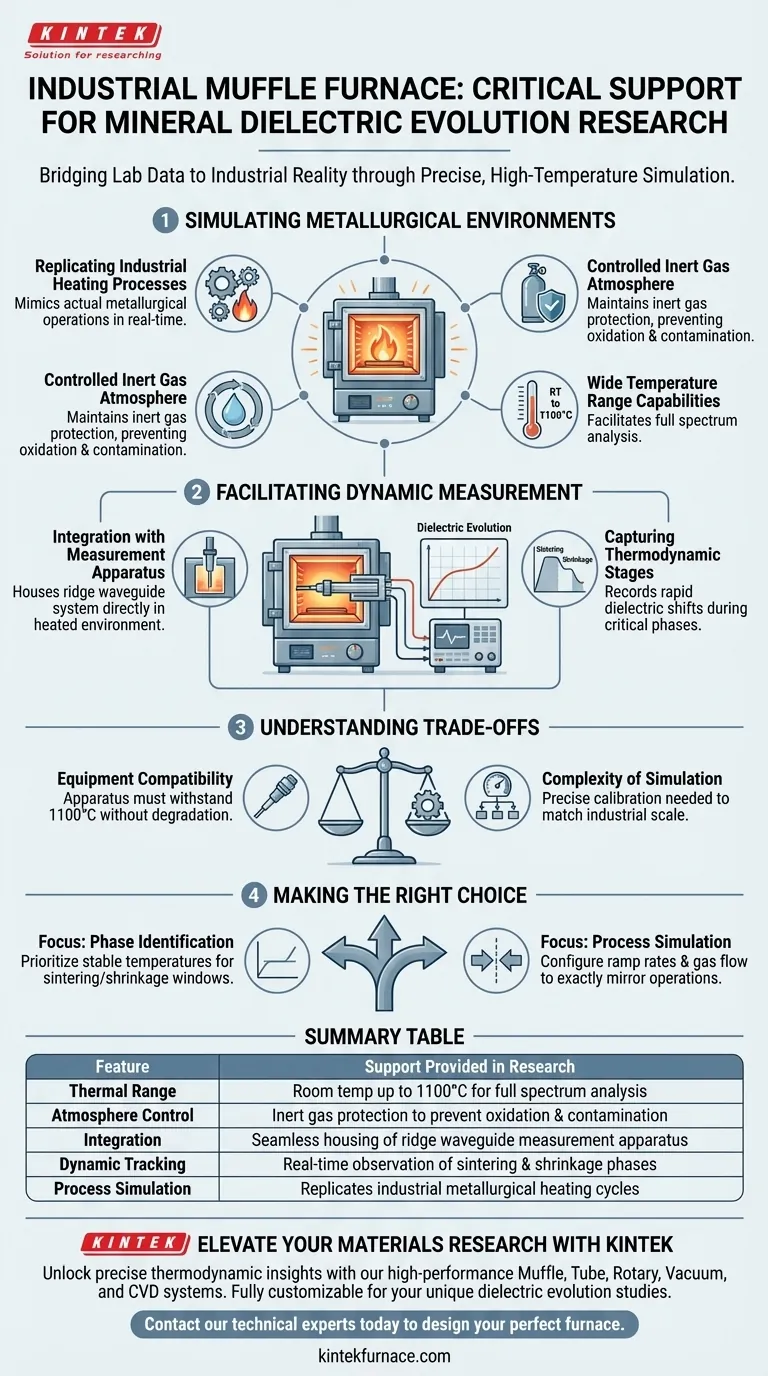

The critical support provided by an industrial muffle furnace lies in its ability to generate a precisely controlled high-temperature environment that integrates seamlessly with ridge waveguide measurement apparatus. This setup enables researchers to simulate authentic metallurgical heating processes, ramping from room temperature up to 1100 degrees Celsius under inert gas protection to capture real-time dielectric shifts.

By replicating the intense thermal conditions of actual industrial processing, the muffle furnace allows for the accurate tracking of dielectric evolution during critical thermodynamic stages, such as sintering and shrinkage.

Simulating Metallurgical Environments

Replicating Industrial Heating Processes

The primary value of the muffle furnace is its ability to mimic the actual heating processes used in metallurgical operations.

Rather than testing materials in a static state, the furnace allows for the observation of minerals as they undergo thermal processing.

Controlled Inert Gas Atmosphere

The furnace supports research by maintaining inert gas protection throughout the heating cycle.

This ensures that the dielectric changes observed are due to thermodynamic evolution, rather than unwanted oxidation or atmospheric contamination.

Wide Temperature Range Capabilities

Research into mineral evolution requires a broad thermal spectrum.

The furnace facilitates temperature increases from room temperature to 1100°C, covering the entire range necessary for most mineral processing studies.

Facilitating Dynamic Measurement

Integration with Measurement Apparatus

The furnace is designed to house the ridge waveguide measurement apparatus within its heated chamber.

This integration is vital because it allows the measurement system to operate directly within the thermal environment, rather than testing samples after they have cooled.

Capturing Thermodynamic Stages

Mineral properties do not change linearly; they evolve through distinct phases.

The muffle furnace enables researchers to record dramatic changes in dielectric properties specifically during sintering and shrinkage phases.

Understanding the Trade-offs

Equipment Compatibility

While the furnace provides the heat, the measurement apparatus inside must withstand the environment.

Researchers must ensure the ridge waveguide system is robust enough to maintain accuracy at 1100°C without physical degradation.

Complexity of Simulation

Simulating industrial processes in a lab setting requires precise calibration.

If the ramp rates or gas flows in the muffle furnace do not perfectly match the industrial scale, the observed dielectric evolution may differ slightly from real-world production results.

Making the Right Choice for Your Research

To effectively utilize an industrial muffle furnace for dielectric evolution studies, align your equipment settings with your specific research goals.

- If your primary focus is Phase Identification: Ensure your furnace can maintain stable temperatures during the sintering and shrinkage windows to capture rapid dielectric shifts.

- If your primary focus is Process Simulation: Configure the furnace ramp rates and inert gas flow to exactly mirror the specific metallurgical operation you are studying.

The muffle furnace is the bridge that transforms static mineral data into a dynamic understanding of material behavior under thermal stress.

Summary Table:

| Feature | Support Provided in Research |

|---|---|

| Thermal Range | Room temperature up to 1100°C for full spectrum analysis |

| Atmosphere Control | Inert gas protection to prevent oxidation and contamination |

| Integration | Seamless housing of ridge waveguide measurement apparatus |

| Dynamic Tracking | Real-time observation of sintering and shrinkage phases |

| Process Simulation | Replicates industrial metallurgical heating cycles |

Elevate Your Materials Research with KINTEK

Unlock precise thermodynamic insights and simulate authentic metallurgical processes with our high-performance heating solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique dielectric evolution study requirements.

Ready to bridge the gap between lab data and industrial reality? Contact our technical experts today to design the perfect furnace for your laboratory’s specific high-temperature needs.

Visual Guide

References

- Rui Xiong, Qian Chen. A High-Temperature and Wide-Permittivity Range Measurement System Based on Ridge Waveguide. DOI: 10.3390/s25020541

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does the feeding and discharging device contribute to the operation of a box furnace? Enhance Safety and Process Control

- What is the function of a high-temperature muffle furnace in improving the mechanical strength of coatings?

- What is the recommended operating temperature to extend the lifespan of the furnace wire? Maximize Longevity with a 50°C Buffer

- Why are box type electric furnaces considered indispensable in industry and laboratories? Unlock Precision and Versatility in Thermal Processing

- What function does a box-type high-temperature furnace serve in converting precursors? Unlock Phase Homogeneity.

- What are the energy efficiency features of modern digital muffle furnaces? Cut Costs with Advanced Insulation and Control

- What is the alternative to a muffle furnace? Choose the Right High-Temp Furnace for Your Process

- How does a high-temperature laboratory furnace contribute to the synthesis of binary magnesium-based alloys?