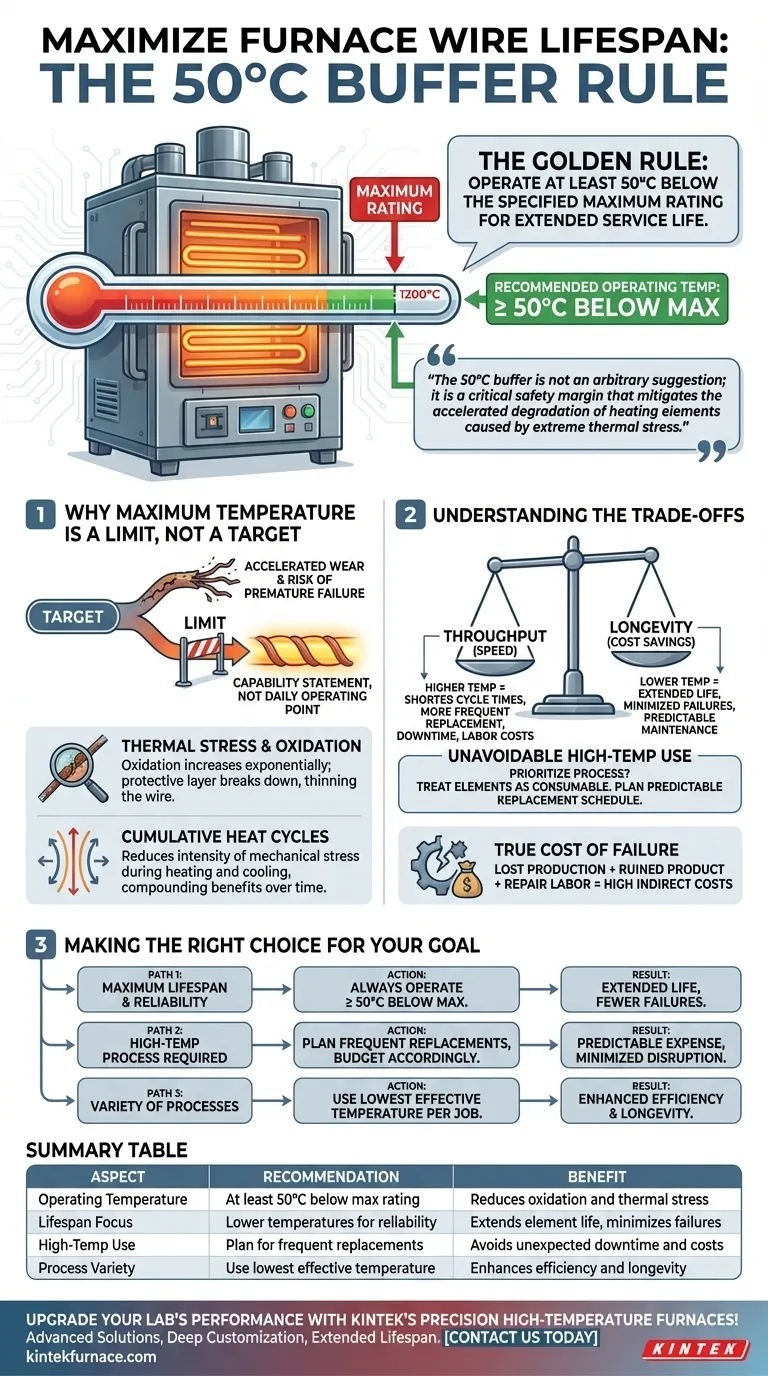

To maximize the lifespan of your furnace wire, you should operate the equipment at a temperature at least 50°C below its specified maximum rating. This simple buffer is the single most effective practice for extending the service life of the heating elements and ensuring the long-term reliability of your furnace.

The 50°C buffer is not an arbitrary suggestion; it is a critical safety margin that mitigates the accelerated degradation of heating elements caused by extreme thermal stress. Operating at the absolute maximum rating drastically shortens the element's life and increases the risk of premature, costly failure.

Why Maximum Temperature Is a Limit, Not a Target

Understanding the principle behind this rule empowers you to make better operational decisions. The "maximum temperature" rating is a statement of capability, not a recommended daily operating point.

The Science of Thermal Stress and Oxidation

Heating elements, typically made of alloys like Kanthal or Nichrome, work by resisting the flow of electricity, which generates intense heat.

At very high temperatures, the material's rate of oxidation increases exponentially. This process forms a protective oxide layer, but running too close to the maximum temperature causes this layer to grow too quickly, become brittle, and flake off, thinning the wire until it fails.

The Meaning of "Maximum Rated Temperature"

The manufacturer's maximum temperature rating defines the absolute peak the furnace can achieve under ideal conditions. It does not account for the cumulative wear and tear of sustained operation at that level.

Treating this limit as a routine target is analogous to constantly running a car's engine at its redline. While possible, it guarantees accelerated wear and dramatically shortens the engine's lifespan.

The Cumulative Effect of Heat Cycles

Component failure is also driven by heat cycles—the expansion and contraction the wire endures every time it heats up and cools down.

Operating at a lower peak temperature reduces the intensity of this mechanical stress during each cycle. Over hundreds or thousands of cycles, this reduction in stress has a significant compounding effect on the wire's structural integrity.

Understanding the Trade-offs

Adhering to this temperature buffer involves a clear choice between operational speed and long-term cost.

Throughput vs. Longevity

The primary trade-off is processing speed versus equipment lifespan. Running hotter may shorten cycle times, but it comes at the direct cost of more frequent element replacement, downtime, and maintenance labor.

When High-Temperature Operation is Unavoidable

Some specialized processes may require temperatures that push closer to the furnace's maximum rating. In these situations, you are consciously making a decision to prioritize process requirements over element longevity.

If this is your reality, you must treat heating elements as a consumable part with a predictable replacement schedule. Budget for this and plan your maintenance accordingly to avoid unexpected and disruptive failures.

The True Cost of Failure

The cost of a failed element is never just the price of the wire. The true cost includes lost production during downtime, potentially ruined product inside the furnace when it failed, and the labor hours required for the repair. A disciplined approach to temperature management minimizes these indirect costs.

Making the Right Choice for Your Goal

Your operational strategy should align with your primary objective. Use the following guidelines to make an informed decision.

- If your primary focus is maximum equipment lifespan and reliability: Always operate at least 50°C below the maximum rating, and even lower if your process allows.

- If your process requires high temperatures near the maximum rating: Acknowledge that frequent element replacement is a necessary cost of operation and plan your maintenance schedule and budget accordingly.

- If you are running a variety of processes: Always use the lowest effective temperature required for the specific job rather than a single high-temperature setting for all work.

Adhering to this temperature discipline transforms furnace maintenance from a reactive emergency into a predictable, manageable expense.

Summary Table:

| Aspect | Recommendation | Benefit |

|---|---|---|

| Operating Temperature | At least 50°C below max rating | Reduces oxidation and thermal stress |

| Lifespan Focus | Lower temperatures for reliability | Extends element life, minimizes failures |

| High-Temp Use | Plan for frequent replacements | Avoids unexpected downtime and costs |

| Process Variety | Use lowest effective temperature | Enhances efficiency and longevity |

Upgrade your lab's performance with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental needs are met, extending equipment lifespan and reducing costs. Contact us today to discuss how we can optimize your furnace operations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis