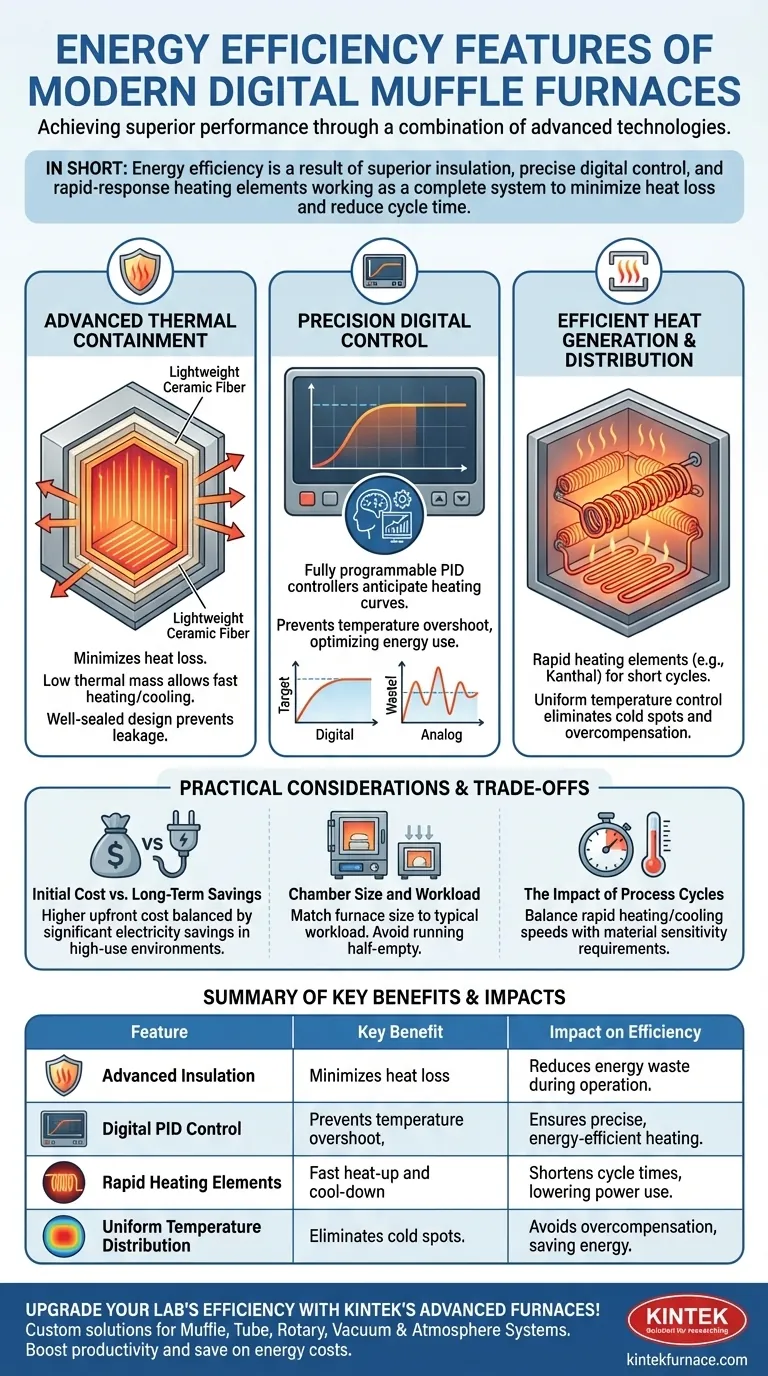

In short, modern digital muffle furnaces achieve energy efficiency not through a single feature, but through a combination of superior insulation, precise digital control, and rapid-response heating elements. These systems work together to heat samples quickly, maintain temperature with minimal energy waste, and reduce overall cycle time, which directly cuts down on power consumption.

The key to understanding muffle furnace efficiency is to see it as a complete system. Advanced insulation minimizes heat loss, while precise digital controllers prevent energy waste from temperature overshoots, ensuring that electricity is converted into usable heat as effectively as possible.

The Core Principles of Muffle Furnace Efficiency

A furnace's primary job is to generate and contain heat. Efficiency is therefore a measure of how well it performs those two tasks. Modern designs excel by optimizing the entire thermal system, from power input to heat containment.

Advanced Thermal Containment

Modern furnaces are built with superior insulation and construction. While older models used heavy, dense firebrick that absorbed and slowly radiated heat, newer designs use lightweight ceramic fiber insulation.

This advanced material has a very low thermal mass, meaning it doesn't absorb much heat itself. This allows the furnace chamber to heat up and cool down much faster.

Furthermore, the "sturdy construction" and use of "premium components" mentioned in design standards point to well-sealed doors and chamber bodies. This robust design minimizes heat leakage, which is a primary source of energy waste. A well-sealed furnace requires less energy to maintain its target temperature.

Precision Digital Control

The shift from analog to digital control is arguably the most significant leap in efficiency. Modern furnaces feature fully programmable PID controllers (Proportional-Integral-Derivative).

A PID controller anticipates the heating curve, reducing power as the chamber approaches the target temperature. This prevents temperature overshoot, a common issue in older furnaces where the system would get too hot, then shut off, wasting energy in the process.

This precise control of heating and cooling rates allows users to create optimized thermal profiles for their specific application, using only the necessary amount of energy for each stage of the process.

Efficient Heat Generation and Distribution

The heating elements themselves are a critical component. The "premium components" in modern furnaces refer to high-quality elements, often made of materials like Kanthal (FeCrAl) alloys, designed for rapid heating and long life.

These elements are strategically placed to ensure highly uniform temperature control throughout the chamber. Uniformity means there are no "cold spots," ensuring the entire sample is processed correctly without needing to run the furnace at a higher-than-necessary temperature to compensate.

Understanding the Trade-offs

While modern furnaces are highly efficient, there are practical considerations and trade-offs to be aware of when selecting and operating a unit.

Initial Cost vs. Long-Term Savings

Furnaces with the most advanced insulation, controllers, and heating elements typically have a higher upfront purchase price. However, this initial investment is often offset by significant long-term savings in electricity costs, especially in high-use laboratory or production environments.

Chamber Size and Workload

A larger furnace will always consume more energy than a smaller one, regardless of its efficiency features. It is crucial to match the furnace size to your typical workload. Consistently running a large, half-empty furnace is inherently inefficient.

The Impact of Process Cycles

Rapid heating and cooling is a hallmark of efficiency, as it reduces total run time. However, very fast heating rates can sometimes be detrimental to certain sensitive materials. The programmability of a modern furnace allows you to balance speed and efficiency against the specific requirements of your process.

Making the Right Choice for Your Goal

When evaluating a muffle furnace, consider how its features align with your primary objective.

- If your primary focus is high throughput: Prioritize models advertised with the fastest heating and cooling rates to maximize the number of sample cycles you can run per day.

- If your primary focus is precision analysis (like TGA or quenching): Focus on the quality of the digital controller and its ability to maintain highly uniform, stable temperatures.

- If your primary focus is long-term operational cost: Invest in a unit with the best possible insulation and robust construction to minimize heat loss and ensure durability over years of use.

By understanding these core efficiency principles, you can confidently select a furnace that meets your technical requirements while minimizing energy consumption.

Summary Table:

| Feature | Key Benefit | Impact on Efficiency |

|---|---|---|

| Advanced Insulation | Minimizes heat loss | Reduces energy waste during operation |

| Digital PID Control | Prevents temperature overshoot | Ensures precise, energy-efficient heating |

| Rapid Heating Elements | Fast heat-up and cool-down | Shortens cycle times, lowering power use |

| Uniform Temperature Distribution | Eliminates cold spots | Avoids overcompensation, saving energy |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise fit for your unique needs, helping you save on energy costs and boost productivity. Contact us today to discuss how our furnaces can transform your operations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity