At its most fundamental level, the feeding and discharging device of a box furnace is responsible for moving materials into and out of the heating chamber. This mechanism ensures that workpieces can be loaded for treatment and unloaded upon completion safely and efficiently.

The true value of a feeding and discharging device is not merely in material transport. Its critical contribution is its ability to perform this task while protecting the integrity of the furnace's internal environment, ensuring the stability and repeatability of the entire thermal process.

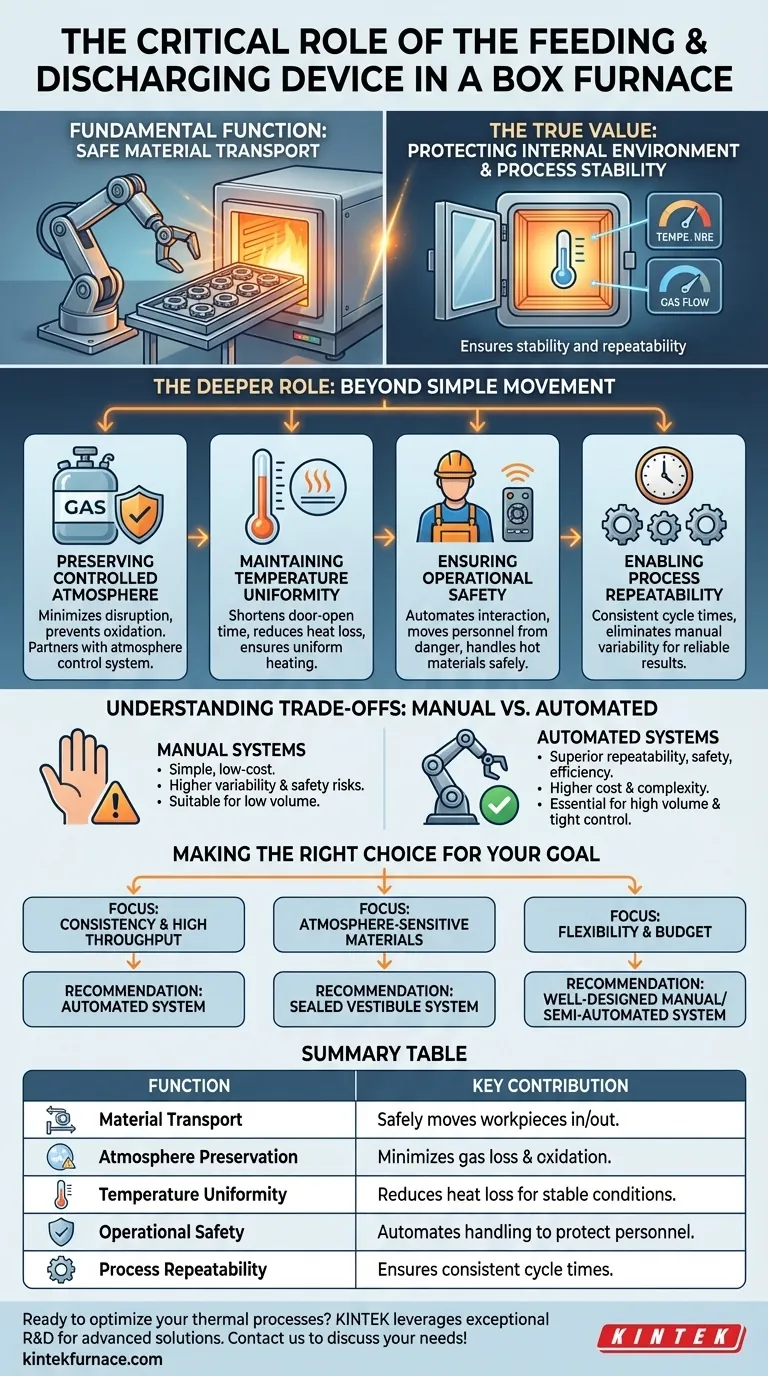

The Deeper Role: Beyond Simple Movement

A box furnace's effectiveness depends on maintaining a highly controlled internal state. The feeding and discharging device is the primary interface between this controlled environment and the outside world, giving it several critical responsibilities.

Preserving the Controlled Atmosphere

Many thermal processes, such as annealing or brazing, require a specific gas atmosphere to prevent oxidation and ensure desired material properties.

The act of opening the furnace door to load or unload parts can ruin this atmosphere. A well-designed feeding system minimizes this disruption by enabling rapid transfers and creating a tight seal when closed. This function is a direct partner to the atmosphere control system, which regulates gas flow and pressure.

Maintaining Temperature Uniformity

Every time the furnace door opens, heat escapes. This creates temperature instability, which can compromise the quality of the heat treatment and increase energy consumption.

An efficient feeding and discharging mechanism shortens the duration the door is open. This minimizes heat loss, helping the furnace return to its target temperature more quickly and ensuring the workpiece is heated uniformly.

Ensuring Operational Safety

Furnaces operate at extreme temperatures, and workpieces can be heavy or cumbersome. Manual loading and unloading present significant risks to operators.

The feeding and discharging device automates this interaction, moving personnel away from immediate danger. It provides a stable, reliable method for handling materials at high temperatures, drastically improving plant safety.

Enabling Process Repeatability

Consistency is the hallmark of quality manufacturing. The outcome of any heat treatment process depends on subjecting every part to the same conditions.

By automating the loading and unloading cycle, the device ensures that each part spends the exact same amount of time under the same conditions. This eliminates the variability inherent in manual operations and is crucial for achieving repeatable, reliable results.

Understanding the Trade-offs

Choosing a feeding and discharging system involves balancing cost, complexity, and process requirements. There is no single best solution for every application.

Manual vs. Automated Systems

Manual systems are simple and low-cost but introduce process variability and higher safety risks. They are suitable for low-volume or less sensitive applications.

Automated systems offer superior repeatability, safety, and efficiency but come with a higher initial investment and increased maintenance complexity. They are essential for high-volume production and processes requiring tight atmospheric control.

Impact on Furnace Design

The choice of feeding device influences the overall furnace design. For example, a system designed to minimize atmospheric disturbance might include pre-heating chambers, vestibules, or specialized door mechanisms.

This integration means the feeding device should be considered early in the furnace specification process, not as a later add-on.

Making the Right Choice for Your Goal

The optimal feeding and discharging system depends entirely on your primary operational objective.

- If your primary focus is process consistency and high throughput: An automated system is non-negotiable to ensure speed and repeatability.

- If your primary focus is treating atmosphere-sensitive materials: Prioritize a system designed to minimize gas and heat loss, such as one with a sealed vestibule.

- If your primary focus is operational flexibility on a limited budget: A well-designed manual or semi-automated system can provide a good balance of control and cost-effectiveness for general-purpose work.

Ultimately, view the feeding and discharging device not as an accessory, but as an active component that directly contributes to the quality and safety of your thermal processing.

Summary Table:

| Function | Key Contribution |

|---|---|

| Material Transport | Safely moves workpieces in and out of the heating chamber |

| Atmosphere Preservation | Minimizes gas loss and oxidation during loading/unloading |

| Temperature Uniformity | Reduces heat loss for stable thermal conditions |

| Operational Safety | Automates handling to protect personnel from high temperatures |

| Process Repeatability | Ensures consistent cycle times for reliable results |

Ready to optimize your thermal processes with a reliable box furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your feeding and discharging device meets your unique experimental needs for enhanced safety and efficiency. Contact us today to discuss how we can support your laboratory goals!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the core function of a high-temperature muffle furnace in silver nanoparticle circuits? Optimize Conductivity

- What morphological changes occur in POMOF after treatment? Unlock High Catalytic Performance via Thermal Evolution

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization