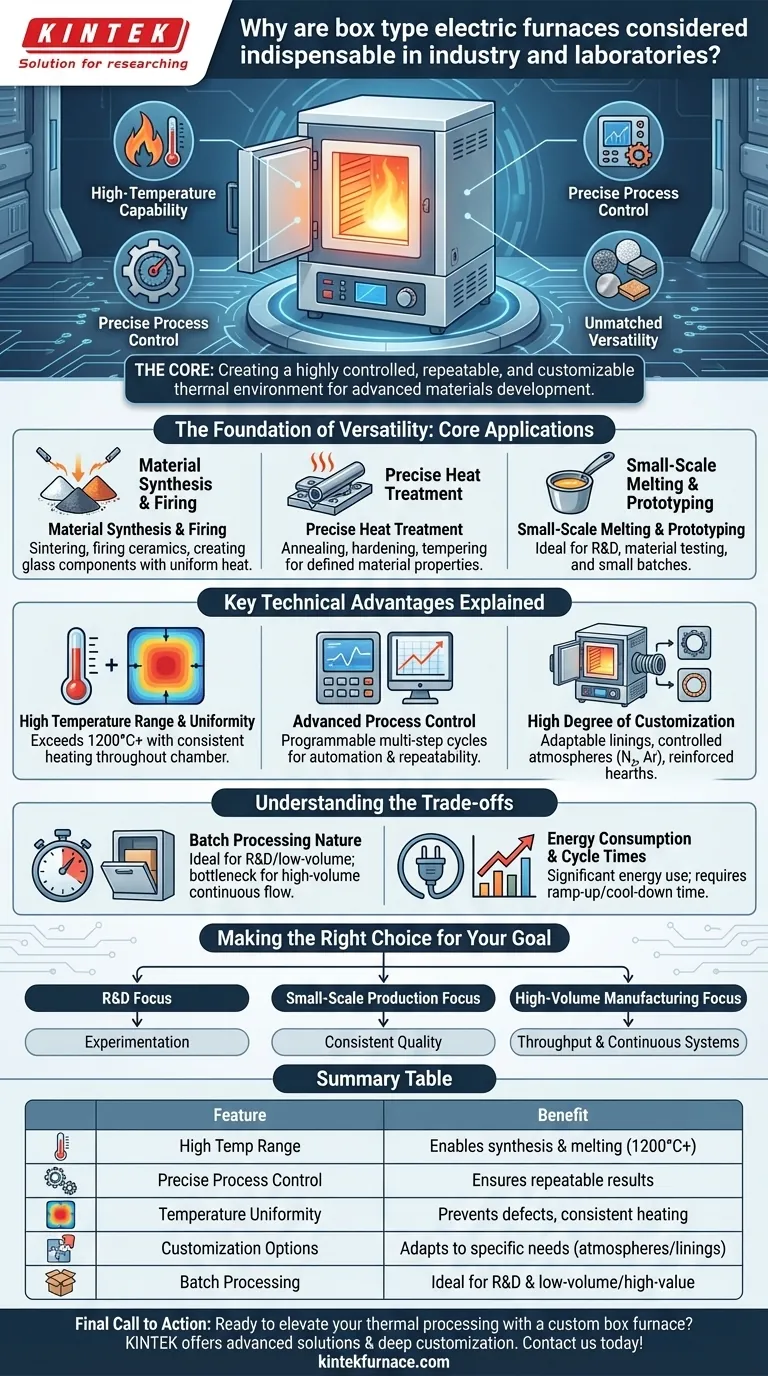

At their core, box-type electric furnaces are indispensable because they offer a unique combination of high-temperature capability, precise process control, and unmatched versatility. This allows them to serve as a foundational tool for a vast range of critical applications in both industrial production and scientific research.

The true value of a box furnace isn't merely its ability to generate heat. It is the ability to create a highly controlled, repeatable, and customizable thermal environment, making it the default solution for developing and processing advanced materials.

The Foundation of Versatility: Core Applications

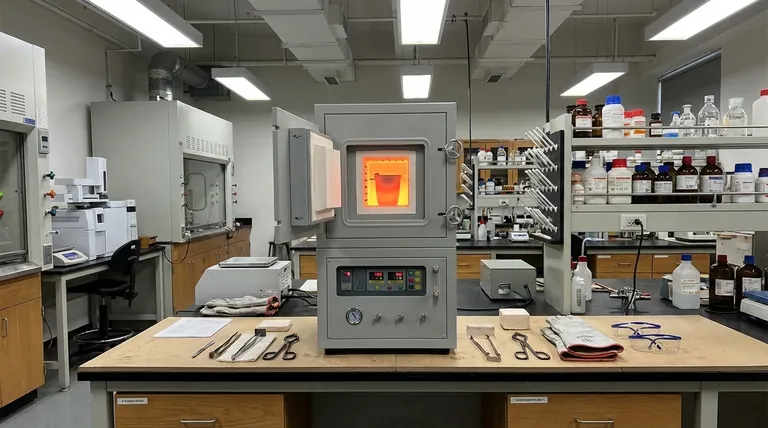

The "box" design is simple, but it enables a wide array of sophisticated thermal processes. It is a controlled environment where heat can be applied with exceptional precision to transform materials.

Material Synthesis and Firing

Many advanced materials are created, not just melted. Processes like sintering (fusing powders into a solid mass), firing ceramics, and creating glass components rely on the uniform, stable heat that a box furnace provides.

Precise Heat Treatment

For metallurgy and materials science, a material's properties are often defined by its thermal history. A box furnace allows for controlled heat treatments like annealing, hardening, and tempering, which are essential for achieving desired strength, ductility, or hardness in metals and alloys.

Small-Scale Melting and Prototyping

In laboratories and small-scale production, these furnaces are ideal for melting smaller batches of metals or alloys. This capability is crucial for R&D, material testing, and creating prototypes before committing to large-scale manufacturing.

Key Technical Advantages Explained

The utility of a box furnace stems directly from several key engineering characteristics that separate it from simpler heating devices.

High Temperature Range and Uniformity

Box furnaces can achieve very high temperatures, often exceeding 1200°C or more. More importantly, they are designed to ensure temperature uniformity throughout the chamber, meaning a component is heated evenly, preventing defects and ensuring consistent results.

Advanced Process Control

Modern box furnaces feature sophisticated digital controllers. This allows operators to program precise, multi-step heating and cooling cycles. This automation and repeatability are non-negotiable for both scientific experiments and quality-controlled industrial production.

High Degree of Customization

The basic design is highly adaptable. Furnaces can be customized with different chamber lining materials, ports for introducing controlled atmospheres (like nitrogen or argon), or reinforced hearths for heavy loads, tailoring them to very specific applications.

Understanding the Trade-offs

While indispensable, the box furnace is not universally perfect. Understanding its inherent limitations is key to using it effectively.

Batch Processing Nature

By design, a box furnace is a batch-processing tool. Materials are loaded, processed, and then unloaded. This is ideal for research or low-volume production but can be a bottleneck for high-volume manufacturing, where continuous-flow tunnel furnaces may be superior.

Heating and Cooling Cycles

The thermal mass required to achieve high, uniform temperatures means these furnaces do not heat up or cool down instantly. These ramp-up and cool-down times must be factored into any production or experimental schedule, as they can significantly impact overall throughput.

Energy Consumption

Reaching and maintaining high temperatures requires a substantial amount of electrical energy. This operational cost is a critical consideration, particularly for larger units or facilities running continuous operations.

Making the Right Choice for Your Goal

The decision to use a box furnace should be driven by your specific objective.

- If your primary focus is research and development: The furnace's precise control and process flexibility make it the ideal platform for experimenting with new materials and thermal profiles.

- If your primary focus is specialized, small-scale production: The reliability and repeatability of a box furnace ensure consistent quality for high-value, low-volume components.

- If your primary focus is high-volume, standardized manufacturing: You must evaluate if the batch-processing nature meets your throughput goals or if a continuous furnace system is a better investment.

Ultimately, the box-type electric furnace remains a cornerstone of modern industry and science because it provides an accessible, reliable, and highly controllable environment for manipulating materials with heat.

Summary Table:

| Feature | Benefit |

|---|---|

| High Temperature Range | Enables material synthesis, firing, and melting up to 1200°C+ |

| Precise Process Control | Ensures repeatable results for experiments and production |

| Temperature Uniformity | Prevents defects and guarantees consistent heating |

| Customization Options | Adapts to specific needs with atmospheres and linings |

| Batch Processing | Ideal for R&D and low-volume, high-value applications |

Ready to elevate your thermal processing with a custom box furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your efficiency and results!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?

- How does a laboratory high-temperature box furnace assist in evaluating concrete fire resistance? | KINTEK