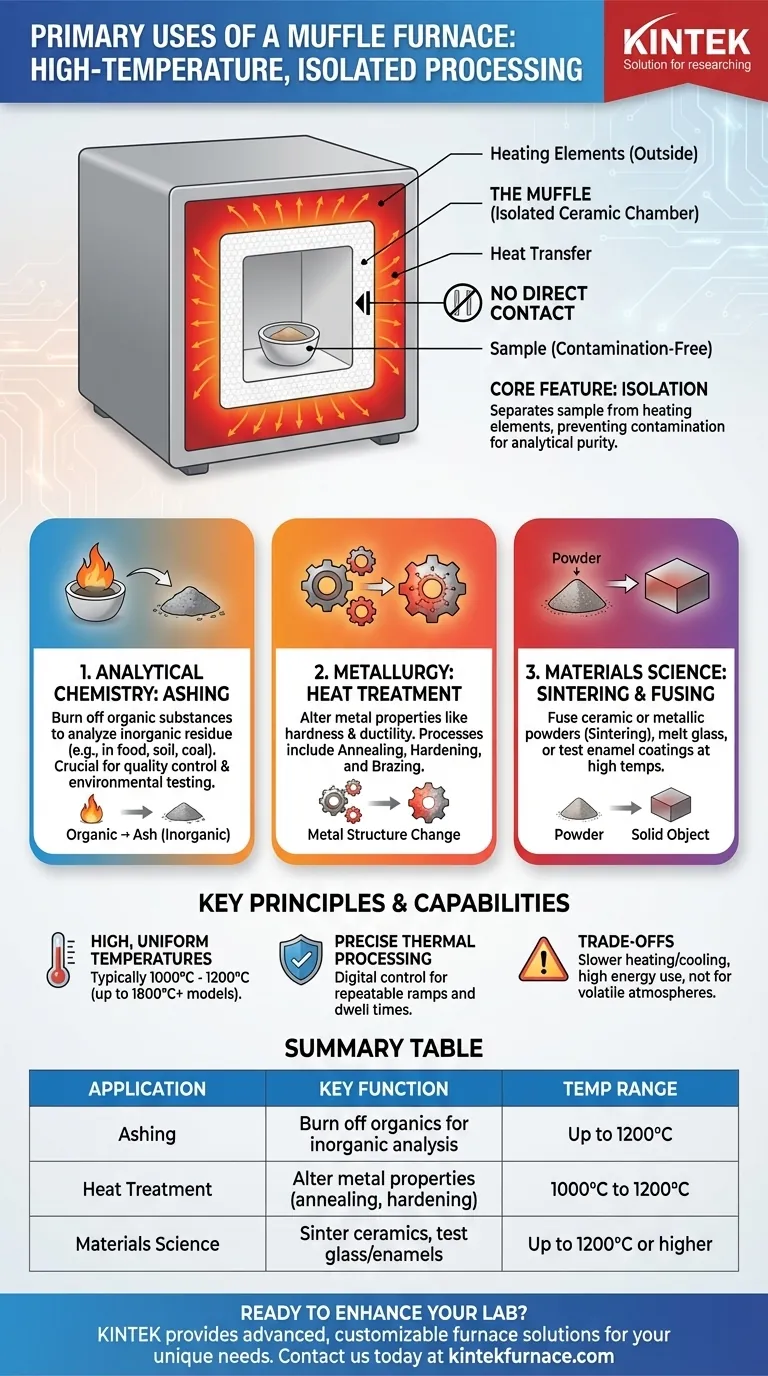

At its core, a muffle furnace is a high-temperature chamber oven used for processes that require thermal treatment in a controlled, isolated environment. Its primary applications involve burning off substances to analyze the residue (ashing), altering the properties of metals through heat treatment, and creating or testing materials like ceramics and glass at extreme temperatures.

The critical feature of a muffle furnace isn't just its high heat, but its design. The sample is placed inside a "muffle," an isolated chamber that separates it from the heating elements, preventing contamination and ensuring analytical purity.

The Principle: Why Use a Muffle Furnace?

A muffle furnace is fundamentally different from a standard laboratory oven. The distinction lies in its ability to provide extremely high, uniform heat within a chemically isolated space, which is critical for specific scientific and industrial processes.

High, Uniform Temperatures

Muffle furnaces are designed to operate at temperatures far exceeding those of conventional ovens, typically ranging from 1000°C to 1200°C (1832°F to 2192°F), with some models reaching even higher. This capability is essential for melting, transforming, or testing the thermal limits of robust materials.

The "Muffle": Preventing Contamination

The name comes from the furnace's key component: the muffle. This is a refractory ceramic chamber that houses the sample. The heating elements are on the outside of this chamber.

This separation is crucial. It prevents combustion byproducts from the heating elements from contaminating the sample, which is vital for obtaining pure, accurate results in analytical chemistry.

Precise Thermal Processing

Modern muffle furnaces offer precise digital control over temperature ramps and dwell times. This allows for repeatable, controlled heating cycles necessary for sophisticated processes like annealing metals or sintering ceramics, where the material's final properties depend on the exact thermal treatment it receives.

Key Applications by Function

The unique capabilities of a muffle furnace lend it to several distinct applications across various fields, from quality control labs to advanced materials research.

Analytical Chemistry: Ashing

Ashing is the most common application. A sample (such as food, soil, plastic, or coal) is heated to a high temperature to completely burn off all organic and volatile substances.

The remaining non-combustible material is ash. By weighing the sample before and after ashing, analysts can precisely determine its inorganic mineral content, a key metric in quality control and environmental testing.

Metallurgy: Heat Treatment

Metals are heat-treated to change their microstructure and, consequently, their physical properties like hardness and ductility.

Common processes include:

- Annealing: Heating and slowly cooling a metal to make it softer and easier to work with.

- Hardening: Heating and rapidly cooling a metal to increase its strength and wear resistance.

- Brazing: Joining two pieces of metal using a filler metal that has a lower melting point.

Materials Science: Ceramics, Glass, and Enamels

The high temperatures are ideal for processing inorganic materials. Sintering is a primary use, where fine ceramic or metallic powders are heated below their melting point until their particles fuse into a solid, dense object.

Muffle furnaces are also used for melting and fusing glass components or testing the durability of enamel coatings.

Quality Control and Research

In R&D and quality assurance, muffle furnaces are used to test the thermal stability of components and materials. This helps determine how a product, from a pharmaceutical drug to an electronic part, will behave under extreme heat.

Understanding the Trade-offs

While powerful, a muffle furnace is a specialized tool with inherent limitations that make it unsuitable for certain tasks.

Slower Heating and Cooling

The heavy insulation required to safely contain extreme temperatures means muffle furnaces have significant thermal mass. They take a long time to heat up to the target temperature and even longer to cool down, making them inefficient for rapid, low-temperature tasks.

Not for Volatile or Reactive Atmospheres

Standard muffle furnaces are designed for heating samples in air. Introducing volatile, flammable, or reactive substances can create a significant safety hazard. Specialized models with features for atmosphere control are required for such processes.

High Energy Consumption

Reaching and maintaining temperatures over 1000°C requires a substantial amount of electrical energy. For simple drying or warming, a standard laboratory oven is a far more energy-efficient choice.

Making the Right Choice for Your Goal

Selecting the correct heating instrument depends entirely on your objective. A muffle furnace is a tool for transformation and high-purity analysis, not simple heating.

- If your primary focus is quantitative analysis (ashing): The contaminant-free environment of a muffle furnace is non-negotiable for accurate results.

- If your primary focus is altering metal properties (heat treatment): The furnace's precise, high-temperature control is essential for achieving specific material characteristics.

- If your primary focus is creating new materials (sintering): A muffle furnace provides the sustained, uniform high heat needed to fuse powders into solid forms.

- If you only need to dry a sample or heat it below 300°C: A conventional laboratory or convection oven is a more efficient and appropriate tool.

Understanding that a muffle furnace is a tool for thermal processing, not just heating, allows you to apply it to the correct scientific or industrial goal.

Summary Table:

| Application | Key Function | Temperature Range |

|---|---|---|

| Ashing | Burn off organic substances to analyze inorganic residue | Up to 1200°C |

| Heat Treatment | Alter metal properties (e.g., annealing, hardening) | 1000°C to 1200°C |

| Materials Science | Sinter ceramics, test glass, and enamels | Up to 1200°C or higher |

Ready to enhance your lab's capabilities with a high-temperature furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs for contamination-free, high-temperature processing. Contact us today to discuss how we can support your research and quality control goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization