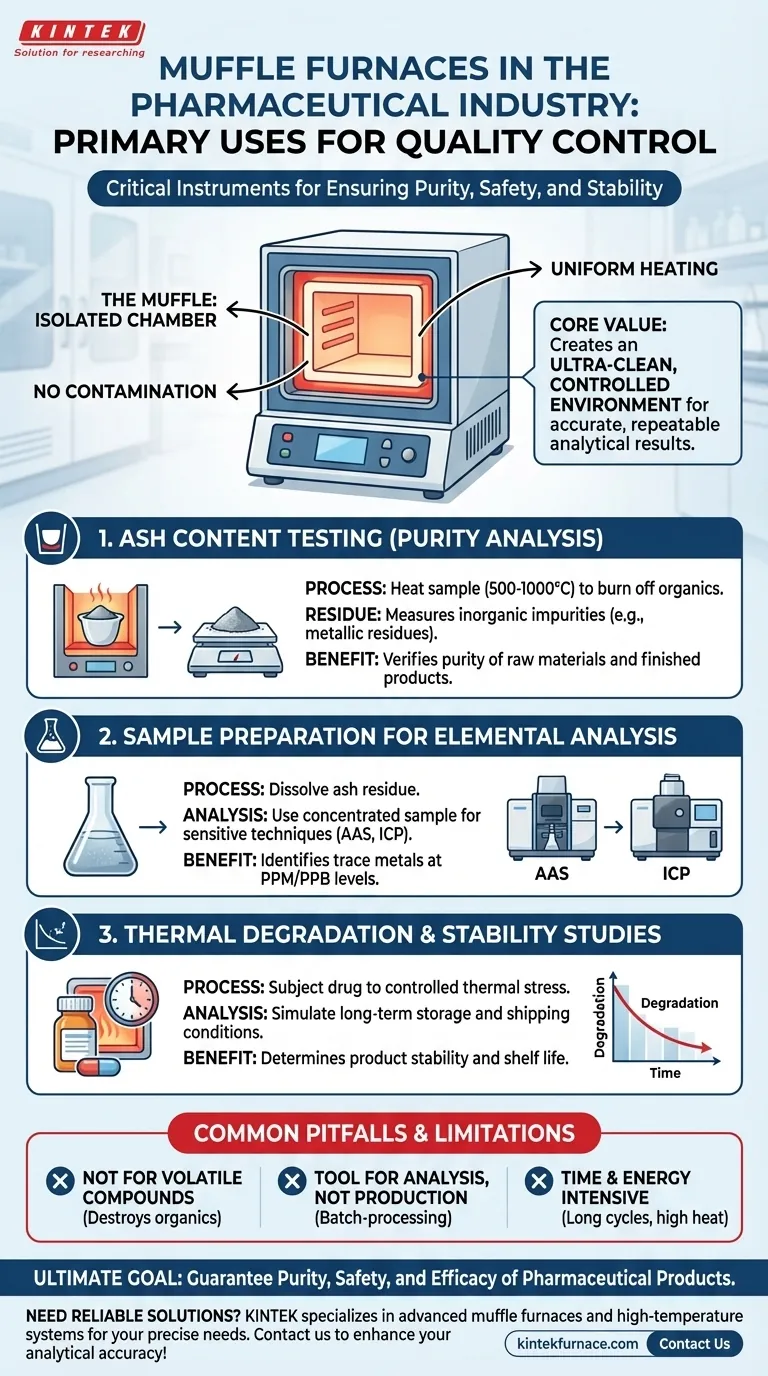

In the pharmaceutical industry, a muffle furnace is not used for manufacturing but serves as a critical analytical instrument for quality control. Its primary functions are to perform ashing for purity analysis, prepare samples for further elemental testing, and conduct thermal degradation studies to ensure drug stability.

The core value of a muffle furnace in pharmaceuticals isn't simply its high heat, but its ability to create an ultra-clean, controlled environment. This ensures that analytical tests for purity and stability are accurate, repeatable, and free from contamination, which is essential for meeting stringent regulatory standards.

The Core Function: An Isolated, High-Temperature Environment

A muffle furnace is fundamentally a high-temperature oven with a critical design feature that gives it its name and purpose.

What is the "Muffle"?

The "muffle" is an insulated inner chamber that houses the sample. It separates the material being heated from the actual heating elements and any contaminants produced by combustion.

This design ensures that the sample is heated uniformly and is not contaminated by the furnace itself. This isolation is non-negotiable for the precise analytical work required in pharmaceuticals.

Why This Matters for Quality Control

In pharmaceutical analysis, even microscopic contamination can invalidate test results. By separating the sample, the muffle furnace guarantees that the only thing being analyzed is the drug substance itself.

This allows scientists to measure impurities or degradation with confidence, knowing the results are not skewed by outside variables.

Primary Applications in Pharmaceutical Analysis

The furnace's clean heating environment is leveraged for several key quality control (QC) procedures.

Ash Content Testing for Purity

The most common application is ashing. This process involves heating a sample to a high temperature (typically 500-1000°C) to completely burn off all organic material.

What remains is a small amount of inorganic, non-combustible residue known as ash.

The weight of this ash is a direct measure of the inorganic impurities (e.g., metallic residues from catalysts, inorganic fillers) in the drug sample. This is a fundamental test for verifying the purity of raw materials and finished products.

Sample Preparation for Elemental Analysis

Ashing is often just the first step. The resulting ash is a concentrated sample of all the inorganic elements present in the original drug.

This prepared ash can then be dissolved and analyzed using highly sensitive techniques like Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma (ICP). These methods can identify and quantify specific trace metals down to parts-per-million or even parts-per-billion levels.

Thermal Degradation and Stability Studies

Muffle furnaces are used to subject a drug product to controlled thermal stress. This helps determine its stability and shelf life.

By exposing the drug to high temperatures for a set period, analysts can simulate the effects of long-term storage or exposure to extreme shipping conditions. The resulting degradation is then measured, providing crucial data for setting expiration dates and storage recommendations.

Common Pitfalls and Limitations

While essential, a muffle furnace is a specific tool with clear limitations that are important to understand.

Not for Analyzing Volatile Compounds

The entire purpose of ashing is to destroy organic compounds. Therefore, a muffle furnace cannot be used to analyze the active pharmaceutical ingredient (API) itself or any other organic component. Its use is focused on the inorganic residue left behind.

A Tool for Analysis, Not Production

Muffle furnaces are batch-processing instruments designed for small samples in a laboratory setting. They are not used for bulk drying or large-scale heat treatment in manufacturing.

Time and Energy Requirements

Reaching and maintaining temperatures of over 500°C is an energy-intensive process. A single ashing cycle can take several hours from heating to cooling, making it a time-consuming step in the analytical workflow.

How to Apply This to Your Goal

Your choice of method depends entirely on the analytical question you need to answer.

- If your primary focus is determining overall inorganic purity: Use the muffle furnace for a "loss on ignition" or gravimetric ashing test to measure the total percentage of non-combustible material.

- If your primary focus is identifying specific metal contaminants: Use the furnace as the sample preparation step to create an ash sample for subsequent analysis via AAS or ICP.

- If your primary focus is assessing product stability and shelf life: Employ the furnace for controlled thermal stress testing as part of a comprehensive stability study protocol.

Ultimately, the muffle furnace is an indispensable tool for generating the precise analytical data needed to guarantee the purity, safety, and efficacy of pharmaceutical products.

Summary Table:

| Application | Purpose | Key Benefit |

|---|---|---|

| Ash Content Testing | Measure inorganic impurities | Determines purity of raw materials and products |

| Sample Preparation | Prepare samples for elemental analysis | Enables trace metal detection via AAS/ICP |

| Thermal Degradation Studies | Assess drug stability and shelf life | Simulates long-term storage conditions |

Need reliable high-temperature solutions for your pharmaceutical lab? KINTEK specializes in advanced muffle furnaces and other high-temperature systems like Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and deep customization capabilities, we deliver tailored solutions to meet your unique experimental needs for precise quality control. Contact us today to enhance your analytical accuracy and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation