The essential materials for muffle furnace construction are refractory ceramics for the inner chamber, high-performance insulation like alumina or ceramic fiber, and a durable outer shell, typically made of stainless steel. These materials are chosen for their ability to withstand extreme temperatures, maintain thermal efficiency, and resist chemical corrosion from samples being heated.

The selection of materials for a muffle furnace is a strategic balance between thermal performance, chemical inertness, and structural integrity. The right combination ensures the creation of a stable, safe, and energy-efficient high-temperature environment tailored to a specific application.

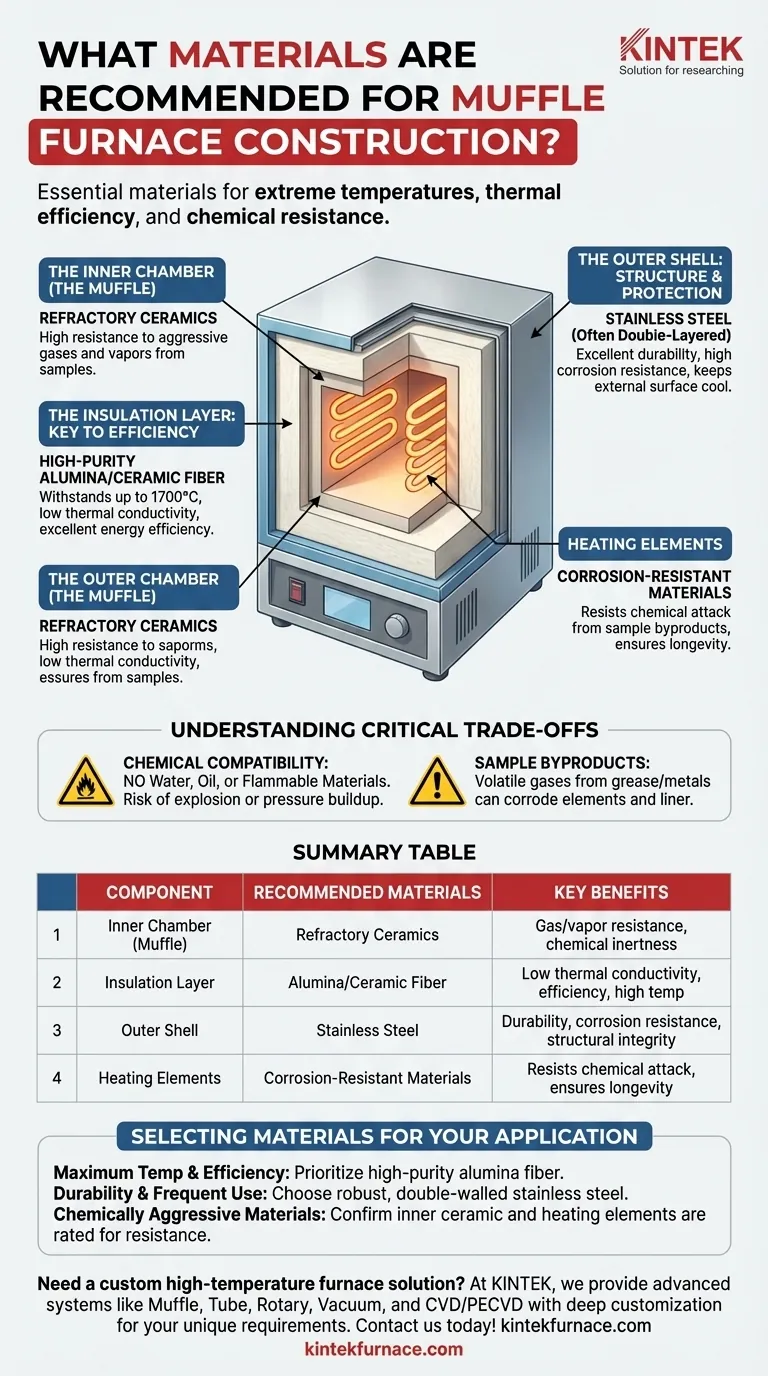

The Anatomy of a Muffle Furnace: A Material-by-Material Breakdown

A muffle furnace is a system of layers, each with a specific function. The material for each layer is critical to the furnace's overall performance and longevity.

The Inner Chamber (The Muffle)

The muffle is the sealed inner chamber that contains the sample. It is the component that faces the most extreme conditions.

Refractory ceramics are the standard material for this part. Their primary advantage is high resistance to the aggressive gases and vapors that can be released from samples during heating.

The Insulation Layer: The Key to Efficiency

Surrounding the muffle is a thick layer of insulation. Its job is to keep heat inside the chamber and ensure the outer surface of the furnace remains safe to touch.

High-purity alumina fiber is an excellent choice, capable of withstanding temperatures up to 1700°C. It offers very low thermal conductivity, meaning it's a poor conductor of heat, which is exactly what you want in an insulator.

Alumina fiber also provides good electrical insulation at high temperatures, which is a critical safety feature.

High-density ceramic fiber is another common option. It is lightweight, fire-resistant, and contributes significantly to the furnace's overall energy efficiency by preventing heat loss.

The Outer Shell: Providing Structure and Protection

The outer casing provides structural support and protects the internal components from the external environment.

Stainless steel is the preferred material for the housing. It offers excellent durability and high resistance to corrosion, ensuring the furnace has a long service life.

Many designs use a double-layer shell structure. This creates an air gap between the inner and outer walls, further improving insulation and helping to keep the external surface temperature low.

The Heating Elements: The Source of Heat

While not a structural material, the choice of heating element is vital. These elements are the source of the heat and are often exposed to the same harsh environment as the muffle.

The references note that volatile gases from samples (such as grease on metals) can corrode the heating elements, shortening their lifespan. Therefore, the element material must be chosen for its ability to resist chemical attack from any byproducts of the heating process.

Understanding the Critical Trade-offs

Choosing the right materials involves more than just picking the one with the highest temperature rating. You must consider the chemical interactions and potential hazards.

Chemical Compatibility is Non-Negotiable

The single most important consideration is the chemical interaction between your samples and the furnace materials.

Placing samples containing water, oil, or other liquids is strictly forbidden. At high temperatures, these will vaporize rapidly, potentially causing explosive pressure buildup or damage to the furnace interior.

Similarly, flammable and explosive materials must never be placed in the furnace, as the combination of high heat and a contained atmosphere creates an extreme risk of accident.

The Hidden Danger of Sample Byproducts

Even seemingly inert materials can cause problems. Heating metals with residual grease, for example, can release volatile gases.

These gases can aggressively attack the heating elements and ceramic liner, leading to premature failure. If you anticipate such off-gassing, you must ensure your furnace's internal components are specifically rated to resist that type of chemical corrosion.

Selecting Materials for Your Specific Application

Your choice of furnace—or the materials you use to build one—should be directly guided by your intended use case.

- If your primary focus is maximum temperature and efficiency: Prioritize a furnace built with high-purity alumina fiber insulation for its superior heat retention and temperature rating.

- If your primary focus is durability and frequent use: A robust, double-walled stainless steel housing is non-negotiable for ensuring long-term structural integrity and corrosion resistance.

- If your primary focus is processing chemically aggressive materials: Confirm that the inner ceramic muffle and the heating elements are specifically rated for resistance to the vapors you expect to generate.

Understanding these material principles empowers you to select or design a furnace that is not only effective but also safe and durable for your specific high-temperature work.

Summary Table:

| Component | Recommended Materials | Key Benefits |

|---|---|---|

| Inner Chamber (Muffle) | Refractory Ceramics | High resistance to gases and vapors, chemical inertness |

| Insulation Layer | Alumina or Ceramic Fiber | Low thermal conductivity, energy efficiency, withstands up to 1700°C |

| Outer Shell | Stainless Steel | Durability, corrosion resistance, structural integrity |

| Heating Elements | Corrosion-Resistant Materials | Resists chemical attack from sample byproducts, ensures longevity |

Need a custom high-temperature furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for enhanced safety, efficiency, and performance. Contact us today to discuss how we can support your laboratory needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation