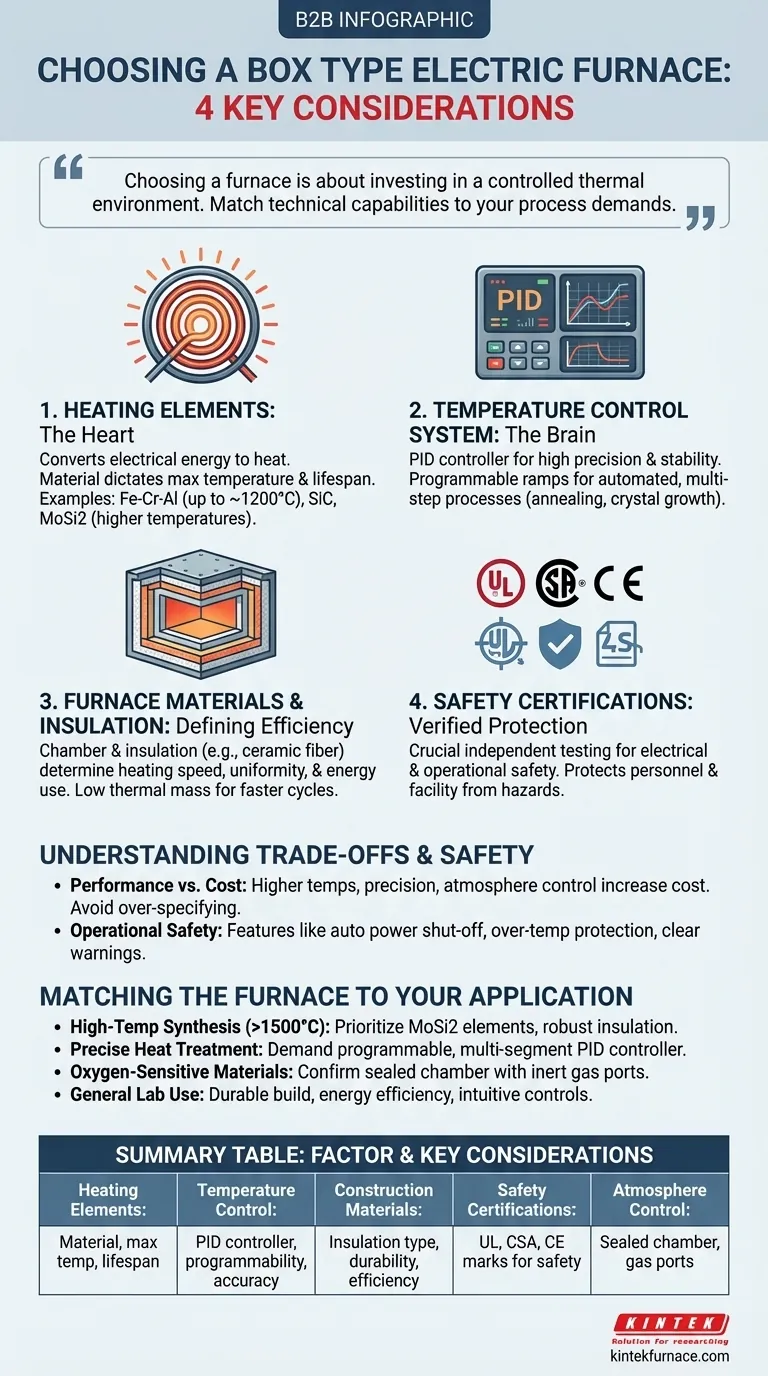

To select the right box-type electric furnace, you must evaluate four key areas: the heating elements, the temperature control system, the furnace construction materials, and the presence of verified safety certifications. These components directly dictate the furnace's performance, reliability, and suitability for your specific scientific or industrial application.

Choosing a furnace is not about acquiring a piece of equipment; it is about investing in a controlled thermal environment. The central goal is to match the furnace’s technical capabilities—its temperature limits, accuracy, and atmospheric control—to the precise demands of your process.

Deconstructing the Core Components

A box furnace appears simple, but its performance hinges on the synergy between a few critical systems. Understanding how each part contributes to the whole is the key to making an informed decision.

Heating Elements: The Heart of the Furnace

Heating elements are the components that convert electrical energy into heat. Their material composition is the single most important factor determining the furnace's maximum operating temperature and service life.

Elements are chosen for specific temperature ranges. For lower to medium temperatures (up to ~1200°C), iron-chromium-aluminum alloys are common. For higher temperatures, materials like silicon carbide (SiC) or molybdenum disilicide (MoSi2) are required, each offering different performance characteristics and lifespans.

Temperature Control System: The Brain of the Operation

The control system dictates the accuracy and stability of the temperature inside the chamber. Modern furnaces use a PID (Proportional-Integral-Derivative) controller, which continuously makes micro-adjustments to maintain the set temperature with high precision.

Look for systems that offer programmable heating and cooling ramps. This allows for automated, multi-step thermal processes, which is essential for applications like annealing, tempering, and crystal growth. This feature is the foundation of the "high temperature control accuracy" and "automatic temperature control" mentioned as key advantages.

Furnace Materials and Insulation: Defining Efficiency

The furnace chamber and surrounding insulation determine heating speed, temperature uniformity, and energy consumption. High-quality ceramic fiber insulation is standard for modern furnaces as it has low thermal mass and excellent insulating properties.

This allows for faster heat-up and cool-down cycles and reduces the amount of energy wasted to the surrounding environment. The chamber material itself must be able to withstand the thermal cycles and any potential chemical reactions from your samples.

Atmosphere Control: Protecting Your Process

Many advanced material processes are sensitive to oxygen at high temperatures. If you are working with such materials, a furnace with atmosphere control is not a luxury—it is a necessity.

This capability involves a tightly sealed chamber and ports that allow you to purge the air and introduce an inert gas, such as argon or nitrogen. This prevents oxidation and ensures the chemical integrity of your material.

Understanding the Trade-offs and Safety Imperatives

Selecting a furnace involves balancing performance requirements with budget and operational realities. An objective assessment of the risks and compromises is critical.

Performance vs. Cost

There is a direct correlation between furnace performance and price. Higher maximum temperatures, more precise controllers, and specialized atmosphere capabilities all add to the cost.

Avoid over-specifying. A furnace rated for 1700°C is an unnecessary expense if your process never exceeds 1100°C. Define your absolute maximum temperature and accuracy requirements first to narrow your options effectively.

The Critical Role of Safety Certifications

Never overlook safety certifications like UL, CSA, or CE marking. These are not marketing labels; they are proof that the furnace has been independently tested and verified to meet stringent electrical and operational safety standards.

A certified furnace protects your personnel and your facility from electrical faults, overheating, and other potential hazards. It is a non-negotiable mark of a professionally engineered product.

Operational Safety and Reliability

The design of the furnace should support safe operation. Features like automatic power shut-off when the door is opened, over-temperature protection, and clear warning indicators are essential.

Before purchasing, consider the procedures mentioned in the manual. A well-designed furnace makes it easier to follow safety protocols, such as ensuring proper power connection and monitoring furnace conditions during a run.

Matching the Furnace to Your Application

Your choice should be guided by your primary technical objective. Use these points to focus your evaluation.

- If your primary focus is high-temperature material synthesis (>1500°C): Prioritize furnaces with molybdenum disilicide (MoSi2) elements and a robust, multi-layer insulation design.

- If your primary focus is precise heat treatment or annealing: Demand a programmable, multi-segment PID controller for precise control over heating and cooling ramps.

- If your primary focus is processing oxygen-sensitive materials: Confirm the furnace has a fully sealed chamber with gas inlet and outlet ports for inert atmosphere control.

- If your primary focus is general lab use with frequent operation: Look for a durable build, excellent energy efficiency from quality insulation, and intuitive, reliable controls.

Making the right choice is about clearly defining your needs to ensure your furnace becomes a reliable and powerful tool for your work.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Heating Elements | Material (e.g., MoSi2 for high temps), max temperature, lifespan |

| Temperature Control | PID controller, programmability, accuracy, ramp rates |

| Construction Materials | Insulation type, chamber durability, energy efficiency |

| Safety Certifications | UL, CSA, CE marks for operational safety |

| Atmosphere Control | Sealed chamber, gas ports for inert environments |

Upgrade your lab's capabilities with KINTEK's advanced box furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization to meet your unique experimental needs. Contact us today to discuss how our furnaces can enhance your precision, safety, and efficiency in thermal processing!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a laboratory high-temperature box furnace assist in evaluating concrete fire resistance? | KINTEK

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate