At its core, a muffle furnace is a high-temperature oven that isolates the material being heated from the heating elements and any combustion byproducts. Its defining characteristic is an inner chamber, or "muffle," which ensures a contamination-free environment for sensitive processes. This makes it indispensable for applications like ashing, annealing, and sintering materials at temperatures often reaching up to 1100°C (2012°F).

The fundamental value of a muffle furnace is not just its ability to get hot, but its ability to do so cleanly. By creating a protective barrier around the sample, it guarantees that the heating process itself does not alter or contaminate the material's composition.

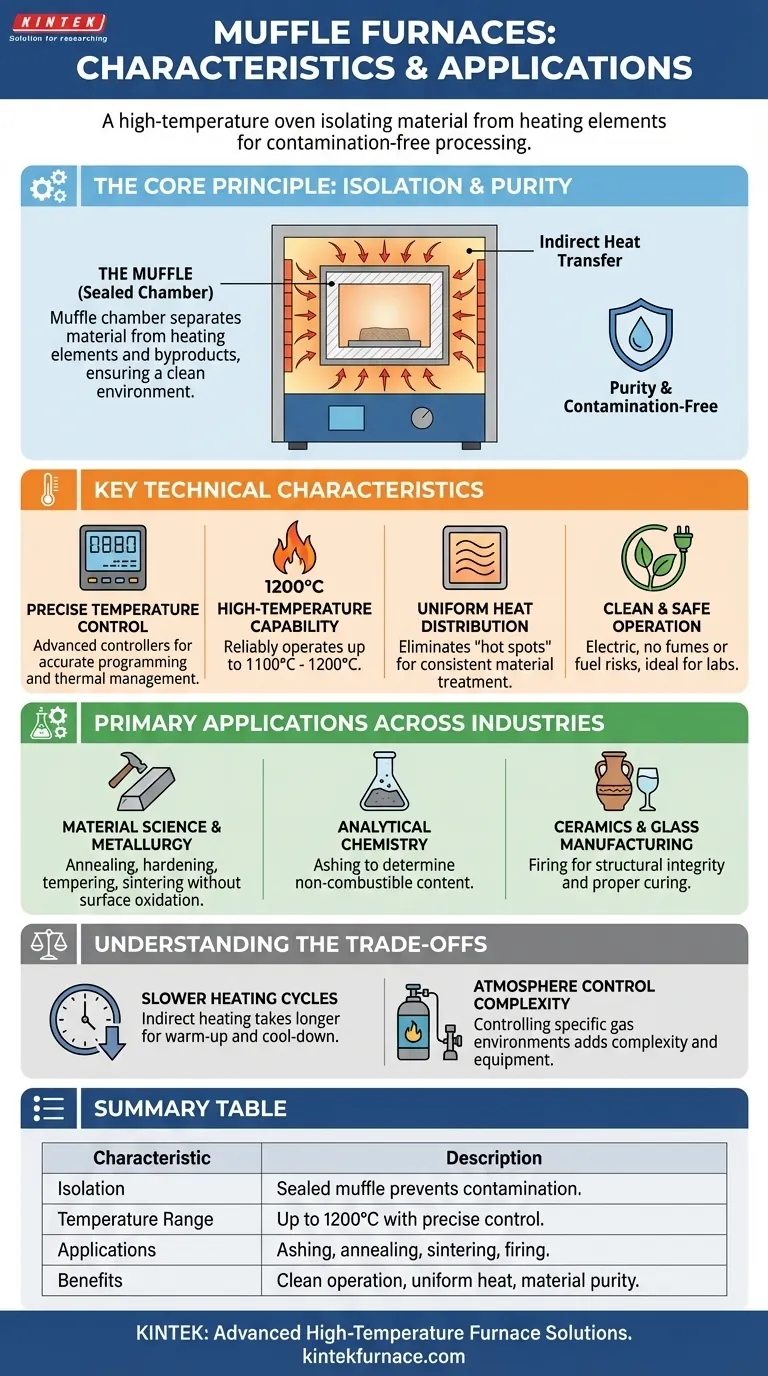

The Core Principle: Isolation and Purity

The name "muffle furnace" directly describes its function. The "muffle" is the key component that separates it from other types of furnaces.

What is the "Muffle"?

A muffle is a sealed, high-temperature chamber that contains the material being processed. It is typically made from heat-resistant ceramics or high-performance metallic alloys with high thermal conductivity.

This chamber acts as a physical barrier, preventing direct contact between the heating elements (or flames, in fuel-fired versions) and the sample inside.

How Heat is Transferred

Because the sample is isolated, heat is transferred indirectly. The furnace heats the outside of the muffle, which then radiates and convects that thermal energy inward.

This method ensures homogenous heating, distributing the temperature evenly throughout the chamber and across the surface of the material being treated.

The Benefit: A Contamination-Free Environment

The primary advantage of this design is purity. In many scientific and industrial processes, byproducts from heating elements or combustion can react with or deposit onto the sample, compromising the results.

The muffle ensures the sample is only exposed to the atmosphere sealed within the chamber, which can be ambient air or a precisely controlled gas.

Key Technical Characteristics

Modern muffle furnaces are defined by a few critical performance features that enable their wide range of applications.

Precise Temperature Control

They are equipped with advanced digital controllers and thermocouples that allow for extremely accurate temperature management. Users can program specific heating rates, hold times, and cooling profiles required for complex processes.

High-Temperature Capability

Standard laboratory and industrial muffle furnaces operate reliably at temperatures up to 1100°C or 1200°C. Specialized models can achieve even higher temperatures for advanced materials research.

Uniform Heat Distribution

The combination of robust insulation and indirect radiant/convective heating eliminates "hot spots." This uniformity is critical for processes like annealing or tempering, where uneven temperatures can create stress and defects in the material.

Clean and Safe Operation

Most modern muffle furnaces are electrically powered, eliminating the fumes, fuel-handling risks, and ventilation requirements associated with combustion-based furnaces. This makes them well-suited for laboratory environments.

Primary Applications Across Industries

A muffle furnace is the tool of choice whenever a process requires clean, precise, and uniform high-temperature heating.

Material Science and Metallurgy

This is a primary field of use. Processes include annealing (softening metal), hardening (strengthening it), tempering (reducing brittleness), sintering (fusing powdered material), and stress relief. In all cases, preventing surface oxidation or contamination is paramount.

Analytical Chemistry and Quality Control

The most common application here is ashing. A sample is heated to a high temperature to completely burn away all organic material, leaving only the inorganic ash behind. This is used to determine the non-combustible content of materials like coal, food, plastics, and other industrial products.

Ceramics and Glass Manufacturing

Muffle furnaces provide the ideal conditions for firing ceramics, pottery, and glass. The slow, controlled, and clean heating process ensures structural integrity, proper curing of glazes, and prevents discoloration from combustion byproducts.

Understanding the Trade-offs

While highly effective, muffle furnaces are not universally optimal for every heating task. Understanding their limitations is key to using them correctly.

Slower Heating Cycles

The indirect heating method and heavy insulation mean that muffle furnaces can take longer to heat up and cool down compared to direct-fired furnaces. This can impact throughput in high-volume industrial settings.

Not for Direct Incineration

A muffle furnace is designed for clean, controlled heating, not bulk waste incineration. While it performs ashing (a type of incineration for analytical purposes), it is not the right tool for general-purpose high-volume burning.

Atmosphere Control Adds Complexity

While many muffle furnaces can be fitted with ports for introducing a controlled atmosphere (like nitrogen or argon), this is often an advanced feature. Basic models operate in ambient air, and managing a specific gas environment requires additional equipment and expertise.

Making the Right Choice for Your Goal

Selecting the correct heating equipment depends entirely on the requirements of your process, with purity being the central question.

- If your primary focus is material purity and precise heat treatment: A muffle furnace is essential for processes like annealing, sintering, or creating high-purity materials where contamination is unacceptable.

- If your primary focus is quantitative analysis: A muffle furnace provides the clean, controlled environment necessary to accurately perform ashing and determine the inorganic content of a sample.

- If your primary focus is simply high-volume heating without purity concerns: A direct-fired furnace or a simpler convection oven may be a more cost-effective and faster alternative.

Ultimately, choosing a muffle furnace is a decision to prioritize a pure and precisely controlled heating environment above all else.

Summary Table:

| Characteristic | Description |

|---|---|

| Isolation | Sealed muffle chamber prevents contamination from heating elements or byproducts |

| Temperature Range | Up to 1100-1200°C, with precise digital control for uniform heating |

| Applications | Ashing, annealing, sintering, and firing in labs and industries |

| Benefits | Clean operation, homogenous heat distribution, and material purity |

Ready to enhance your laboratory's capabilities with a custom muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique experimental needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in material science, analytical chemistry, or ceramics, we can help you achieve precise, contamination-free heating for superior results. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis