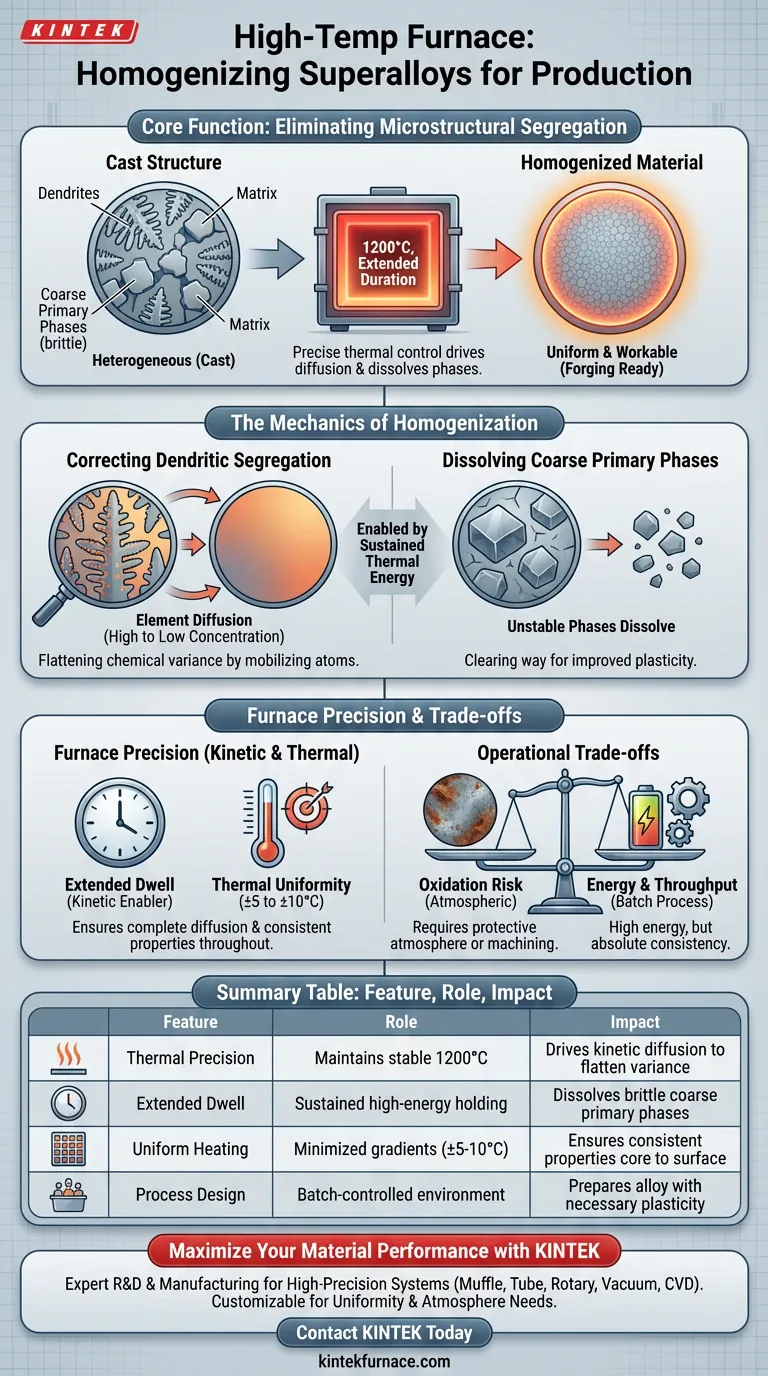

The primary function is eliminating microstructural segregation through precise thermal control. During the homogenization stage of superalloy production, a high-temperature box resistance furnace maintains the material at approximately 1200°C for an extended duration. This sustained thermal environment drives the diffusion of segregated elements, dissolving coarse primary phases and correcting compositional non-uniformity to ensure the alloy is plastic enough for subsequent forging.

By providing a stable, high-energy environment, the furnace enables the kinetic diffusion necessary to transform a heterogeneous cast structure into a uniform, workable material capable of withstanding deformation.

The Mechanics of Homogenization

To understand the furnace's role, you must first understand the problem it solves: the natural inconsistencies of the casting process.

Correcting Dendritic Segregation

When superalloys are cast, they solidify in tree-like structures called dendrites. This rapid cooling creates compositional non-uniformity, where alloying elements are unevenly distributed between the dendrite arms and the spaces between them.

The box resistance furnace provides the thermal energy required to mobilize these atoms. By holding the temperature at 1200°C, the furnace forces these segregated elements to diffuse from areas of high concentration to low concentration, effectively flattening the chemical variance.

Dissolving Coarse Primary Phases

Casting often results in the formation of coarse primary phases—large, brittle structures that can crack during forging.

The furnace maintains the alloy at a temperature where these phases become unstable. Over the extended holding period, these coarse structures dissolve back into the matrix, clearing the way for a more uniform microstructure that offers improved plasticity.

The Role of Furnace Precision

A standard furnace cannot achieve these results; the specific capabilities of the box resistance design are critical to the outcome.

Ensuring Kinetic Conditions

Homogenization is a time-dependent process governed by kinetics. The furnace acts as a kinetic enabler, holding the material in a specific thermal window (e.g., 1200°C) long enough for slow-moving atoms to migrate significantly.

Without this extended dwell time, the diffusion would be incomplete, leaving behind "remnant" segregation that compromises the alloy's mechanical properties.

Guaranteeing Thermal Uniformity

For the material to be uniform, the heat source must be uniform. High-quality box resistance furnaces utilize strategic heating element arrangements and circulating fans to minimize thermal gradients.

This design typically achieves a temperature distribution within ±5 to ±10°C. This precision ensures that the core of the workpiece receives the same heat treatment as the surface, preventing uneven grain growth or incomplete homogenization.

Understanding the Trade-offs

While effective, the high-temperature box resistance furnace presents specific operational considerations compared to other technologies like vacuum furnaces.

Risk of Oxidation

Standard box resistance furnaces often operate under atmospheric pressure. At 1200°C, superalloys are highly susceptible to oxidation and scaling.

Unless the furnace is equipped with a specific protective atmosphere system, the surface of the workpiece may degrade, requiring significant machining later to remove the oxide layer.

Energy Consumption vs. Throughput

Maintaining 1200°C for extended periods requires substantial energy input.

The "box" design is often a batch process. While this allows for excellent control over a specific group of parts, it creates a bottleneck compared to continuous furnaces. You are trading processing speed for the absolute microstructural consistency required by high-performance superalloys.

Making the Right Choice for Your Goal

The effectiveness of homogenization depends on aligning furnace capabilities with your material requirements.

- If your primary focus is forging workability: Ensure the furnace can maintain 1200°C strictly, as this maximizes the dissolution of brittle phases that cause cracking during deformation.

- If your primary focus is part consistency: Prioritize furnaces with advanced circulation fans and element placement to guarantee the ±5-10°C uniformity standard.

- If your primary focus is surface finish: Consider the limitations of a standard box furnace regarding oxidation and evaluate if a protective atmosphere or vacuum alternative is necessary.

Ultimately, the furnace is not just a heater; it is a precision tool used to rewrite the chemical history of the cast alloy.

Summary Table:

| Feature | Role in Homogenization | Impact on Superalloy Quality |

|---|---|---|

| Thermal Precision | Maintains stable 1200°C environment | Drives kinetic diffusion to flatten chemical variance |

| Extended Dwell | Sustained high-energy holding | Dissolves brittle coarse primary phases |

| Uniform Heating | Minimized gradients (±5-10°C) | Ensures consistent properties from core to surface |

| Process Design | Batch-controlled environment | Prepares alloy with necessary plasticity for forging |

Maximize Your Material Performance with KINTEK

Don't let microstructural inconsistencies compromise your high-performance superalloys. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your specific homogenization and thermal processing needs.

Whether you require absolute thermal uniformity or protective atmospheres to prevent oxidation, our engineering team is ready to design the perfect high-temperature furnace for your laboratory or production line. Contact KINTEK today to discuss your unique heating requirements!

Visual Guide

References

- Byungil Kang, Young‐Jig Kim. Microstructural Analysis on Grain Boundary of Boron– and Zirconium–Containing Wrought Nickel-Based Superalloys. DOI: 10.3390/cryst14030290

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How precise is the temperature control in box type high-temperature resistance furnaces? Achieve Superior Heat Treatment Precision

- What are the energy efficiency features of modern digital muffle furnaces? Cut Costs with Advanced Insulation and Control

- What is the difference between a muffle furnace and an oven? A Guide to High-Temperature Processing Purity

- What industries commonly use muffle furnaces? Essential for Labs, Metallurgy, and More

- What role does a box muffle furnace play in T-SAC primary annealing? Achieving Precise Gradient Decomposition

- What is the purpose of a high-temperature muffle furnace for rare earth oxalate calcination? Achieve High-Purity REOs

- Why is a high-temperature laboratory furnace used for the recalcination of deactivated LDH catalysts? Restore Performance

- What materials can be processed in a muffle furnace? Explore Versatile High-Temp Solutions