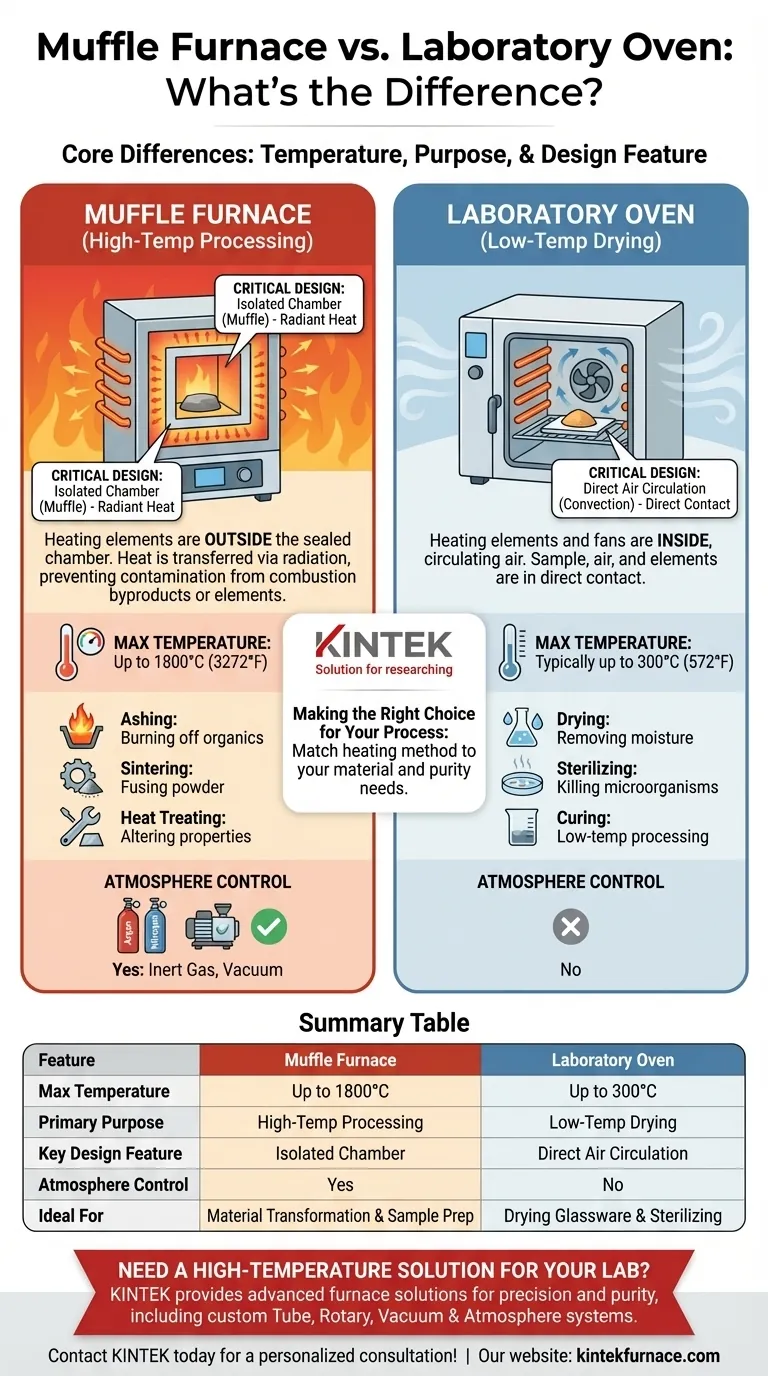

At their core, the difference between a muffle furnace and an oven comes down to three factors: maximum temperature, primary purpose, and a critical design feature. While a laboratory oven is designed for low-temperature drying and heating, a muffle furnace is a specialized high-temperature tool that isolates the material being heated from the heat source, ensuring process purity.

A standard oven heats materials at relatively low temperatures, often circulating air directly over the sample. A muffle furnace, in contrast, uses a shielded chamber (the "muffle") to provide extremely high, uncontaminated heat for precise material processing.

The Fundamental Difference: Isolation and Heat

The most significant distinction lies in how each device delivers heat and isolates the sample. This design choice dictates their vastly different applications.

How a Muffle Furnace Works

A muffle furnace contains a sealed inner chamber made of a high-temperature ceramic or metallic alloy. The heating elements are positioned outside of this chamber.

Heat is transferred to the sample primarily through radiation, not direct contact or convection. This indirect heating method prevents any contamination from combustion byproducts or flakes from the heating elements.

This isolation is critical for processes where purity is paramount, such as preparing samples for chemical analysis.

How a Conventional Oven Works

Most laboratory or industrial ovens heat a chamber to much lower temperatures, typically up to 300°C (572°F).

Heating elements are often located inside the chamber, and fans may be used to circulate air (convection) for more uniform heating. This means the air, the heating elements, and the sample are all in direct contact.

This design is perfectly suitable for simple tasks like drying glassware, removing moisture from samples, or curing materials at low temperatures.

Key Distinctions in Performance and Use

The core design difference results in dramatically different capabilities and applications for each device.

Temperature Range and Purpose

An oven's primary purpose is low-temperature drying, baking, and sterilizing. Its range is limited, making it unsuitable for metallurgy or high-temperature chemistry.

A muffle furnace is built for high-temperature material transformation. It can reach 1500°C (2732°F) or even 1800°C (3272°F), enabling processes like:

- Ashing: Burning off organic substances to determine inorganic content.

- Sintering: Fusing powdered material together with heat.

- Heat Treating: Altering the physical and chemical properties of metals.

Atmospheric Control

The sealed chamber of a muffle furnace allows for atmosphere modification. Ports can be added to introduce inert gases (like argon or nitrogen) or create a vacuum.

This prevents oxidation and other unwanted chemical reactions at high temperatures, a level of control that is impossible in a standard oven.

Understanding the Trade-offs and Alternatives

Choosing a muffle furnace means prioritizing purity and temperature over other factors. It's also important to understand how it compares to other types of furnaces.

Muffle Furnace vs. Tube Furnace

A tube furnace can reach similar temperatures but uses a narrow, cylindrical heating chamber.

A tube furnace offers more precise control over gas flow and temperature gradients across the sample. However, a muffle furnace is better for heating larger or irregularly shaped samples that won't fit in a tube.

Batch vs. Continuous Processing

Muffle furnaces are batch processors. A sample is placed inside, heated for a set duration, and then removed.

This contrasts with continuous systems like pusher furnaces, which constantly move material through a heating zone. Muffle furnaces are ideal for lab-scale work, research, and quality control.

Cost and Complexity

A muffle furnace is a more specialized and therefore more expensive piece of equipment than a general-purpose laboratory oven. Its operation requires a greater understanding of high-temperature processes and safety protocols.

Making the Right Choice for Your Process

Your decision should be guided by the specific temperature and purity requirements of your application.

- If your primary focus is drying, curing, or gentle heating below 300°C: A conventional laboratory oven is the correct and most cost-effective tool.

- If your primary focus is high-temperature material processing like ashing, sintering, or metal treatment: A muffle furnace is necessary to achieve the required temperatures and process purity.

- If your primary focus is high-temperature processing with precise control over gas flow for a smaller, uniform sample: A tube furnace may be a better choice than a muffle furnace.

Ultimately, selecting the right equipment is about matching the heating method to the demands of your material and the goals of your process.

Summary Table:

| Feature | Muffle Furnace | Laboratory Oven |

|---|---|---|

| Max Temperature | Up to 1800°C (3272°F) | Typically up to 300°C (572°F) |

| Primary Purpose | High-temperature processing (ashing, sintering) | Low-temperature drying, baking, curing |

| Key Design Feature | Isolated chamber (muffle) for contamination-free heating | Direct air circulation (convection) |

| Atmosphere Control | Yes (inert gas, vacuum) | No |

| Ideal For | Material transformation, sample preparation for analysis | Drying glassware, removing moisture, sterilizing |

Need a High-Temperature Solution for Your Lab?

Choosing the right equipment is critical for your process's success. KINTEK provides advanced high-temperature furnace solutions for diverse laboratories.

- Precision and Purity: Our Muffle Furnaces, with their isolated heating chambers, ensure contamination-free processing for applications like ashing and sintering.

- Deep Customization: Leveraging exceptional R&D and in-house manufacturing, we tailor our furnaces—including Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems—to meet your unique experimental requirements.

Let our experts help you select the perfect furnace for your specific temperature and purity needs.

Contact KINTEL today for a personalized consultation!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization