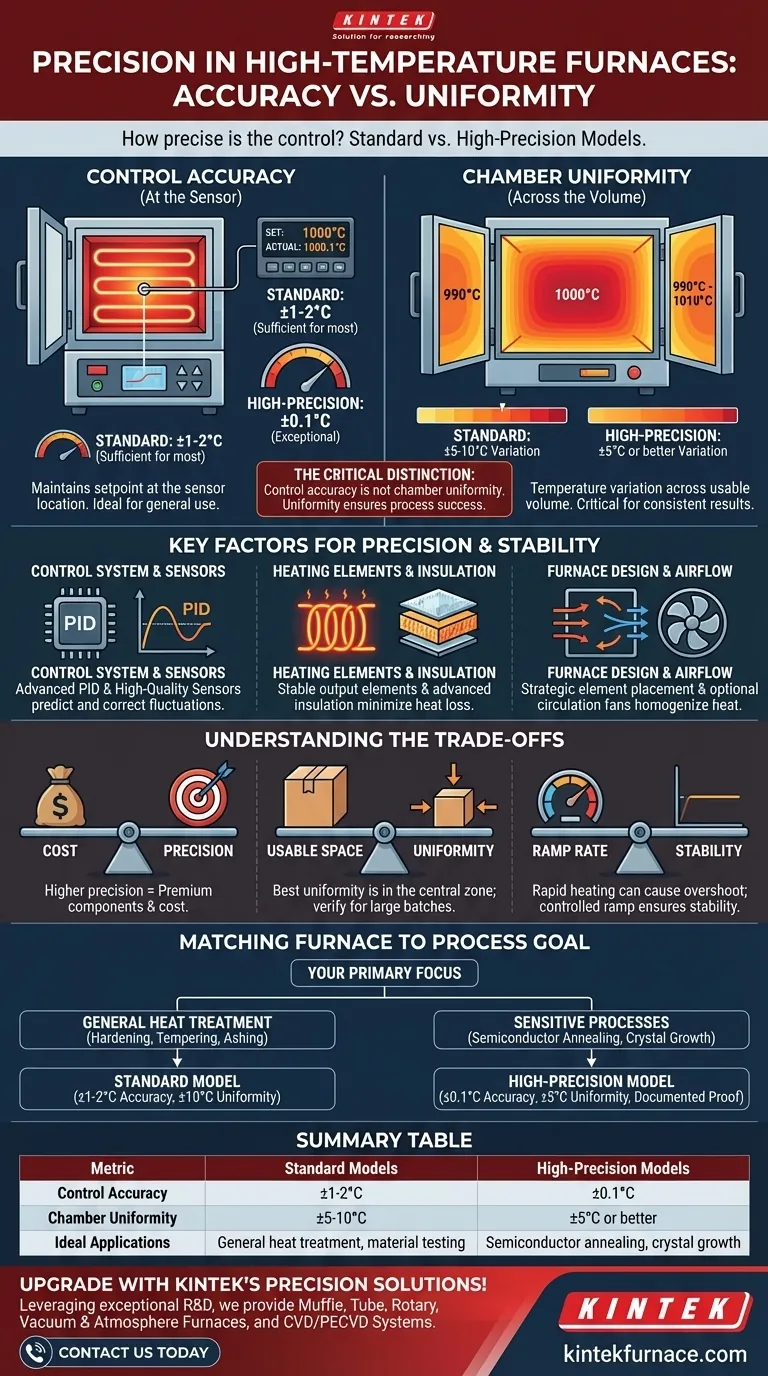

In short, modern box-type high-temperature resistance furnaces offer excellent temperature control. Standard models typically achieve a control accuracy of ±1-2°C, which is sufficient for most heat treatment applications. For more demanding processes, high-precision models are available that can maintain temperatures to an exceptional ±0.1°C.

The critical distinction to understand is not just the control accuracy at a single point, but the temperature uniformity across the entire chamber. While the controller may be highly accurate, the actual temperature variation your material experiences is the more important factor for process success.

Deconstructing Temperature Performance: Accuracy vs. Uniformity

Many users focus solely on the advertised control accuracy, but this only tells part of the story. To ensure a successful outcome, you must understand both accuracy and uniformity.

Control Accuracy: What the System Reports

Control accuracy refers to how closely the furnace's temperature controller can maintain the setpoint at the specific location of the temperature sensor (usually a thermocouple).

A standard accuracy of ±1-2°C is achieved through high-quality sensors and sophisticated PID (Proportional-Integral-Derivative) control systems. This level of precision is ideal for general-purpose applications like hardening, tempering, and sintering of metals and ceramics.

For highly sensitive work, such as semiconductor material annealing, models achieving ±0.1°C provide the tight control necessary to meet stringent process windows.

Chamber Uniformity: The Reality Inside the Box

Temperature uniformity is the measure of temperature variation across the entire usable volume of the furnace chamber. This is often the more critical metric for ensuring consistent results.

Even with precise control, it's common to have a temperature gradient inside the chamber. Most standard box furnaces maintain a uniformity of ±5-10°C. This means that if you set the furnace to 1000°C, some parts of your workpiece could be at 990°C while others are at 1010°C.

This variation is caused by heat loss near the door, element placement, and natural convection patterns.

Key Factors That Determine Precision and Stability

The performance of a furnace is not an accident; it's the result of carefully engineered components working together.

The Control System and Sensors

The "brain" of the furnace is its temperature control system. High-precision systems use advanced algorithms to predict and correct temperature fluctuations, preventing overshoot and maintaining a stable setpoint. The quality and placement of the sensor are paramount to providing accurate feedback to this system.

Heating Elements and Insulation

High-quality heating elements, such as those made from silicon carbide or molybdenum disilicide, provide consistent and stable heat output. They are paired with advanced, multi-layer insulation materials that minimize heat loss, which not only improves energy efficiency but also contributes significantly to temperature stability.

Furnace Design and Airflow

The physical design of the furnace is crucial for uniformity. Engineers carefully arrange heating elements on multiple sides of the chamber to create an even field of radiant heat. For lower temperature ranges or specific processes, some furnaces incorporate circulating fans to actively homogenize the air, drastically improving temperature uniformity.

Understanding the Trade-offs

Selecting a furnace requires balancing performance requirements with practical constraints. Being aware of the trade-offs is key to making an informed decision.

The Cost of Ultimate Precision

Achieving superior accuracy (±0.1°C) and uniformity (±5°C or better) requires premium components, more complex engineering, and often individual calibration. These features come at a significantly higher initial cost compared to standard models.

Uniformity vs. Usable Space

The specified temperature uniformity rating typically applies to a defined central zone within the furnace. The areas closest to the walls, corners, and door will almost always fall outside this range. If you need to process large parts or full batches, you must verify that the furnace's uniform work zone meets your needs.

Ramp Rate vs. Stability

A rapid heating rate is often desirable to reduce cycle times. However, aggressive heating can lead to the temperature overshooting the setpoint before the controller can stabilize it. For sensitive processes, a slower, more controlled ramp may be necessary to ensure thermal stability is maintained throughout the cycle.

Matching the Furnace to Your Process Goal

Your choice should be dictated by the specific requirements of your application, not just the best specifications available.

- If your primary focus is general heat treatment, material testing, or ashing: A standard furnace with ±1-2°C control accuracy and a uniformity of ±10°C is typically sufficient and provides the best value.

- If your primary focus is sensitive processes like semiconductor annealing, crystal growth, or advanced ceramics sintering: You must invest in a high-precision model and, most importantly, request documented proof of its chamber temperature uniformity.

Understanding the distinction between control accuracy and chamber uniformity is the key to selecting a furnace that delivers reliable and repeatable results.

Summary Table:

| Metric | Standard Models | High-Precision Models |

|---|---|---|

| Control Accuracy | ±1-2°C | ±0.1°C |

| Chamber Uniformity | ±5-10°C | ±5°C or better |

| Ideal Applications | General heat treatment, material testing, ashing | Semiconductor annealing, crystal growth, advanced ceramics sintering |

Upgrade your laboratory with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior temperature control and uniformity. Contact us today to discuss how our furnaces can enhance your process reliability and efficiency!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the significance of using a muffle furnace to determine the ash content of biochar? Master Material Performance

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control