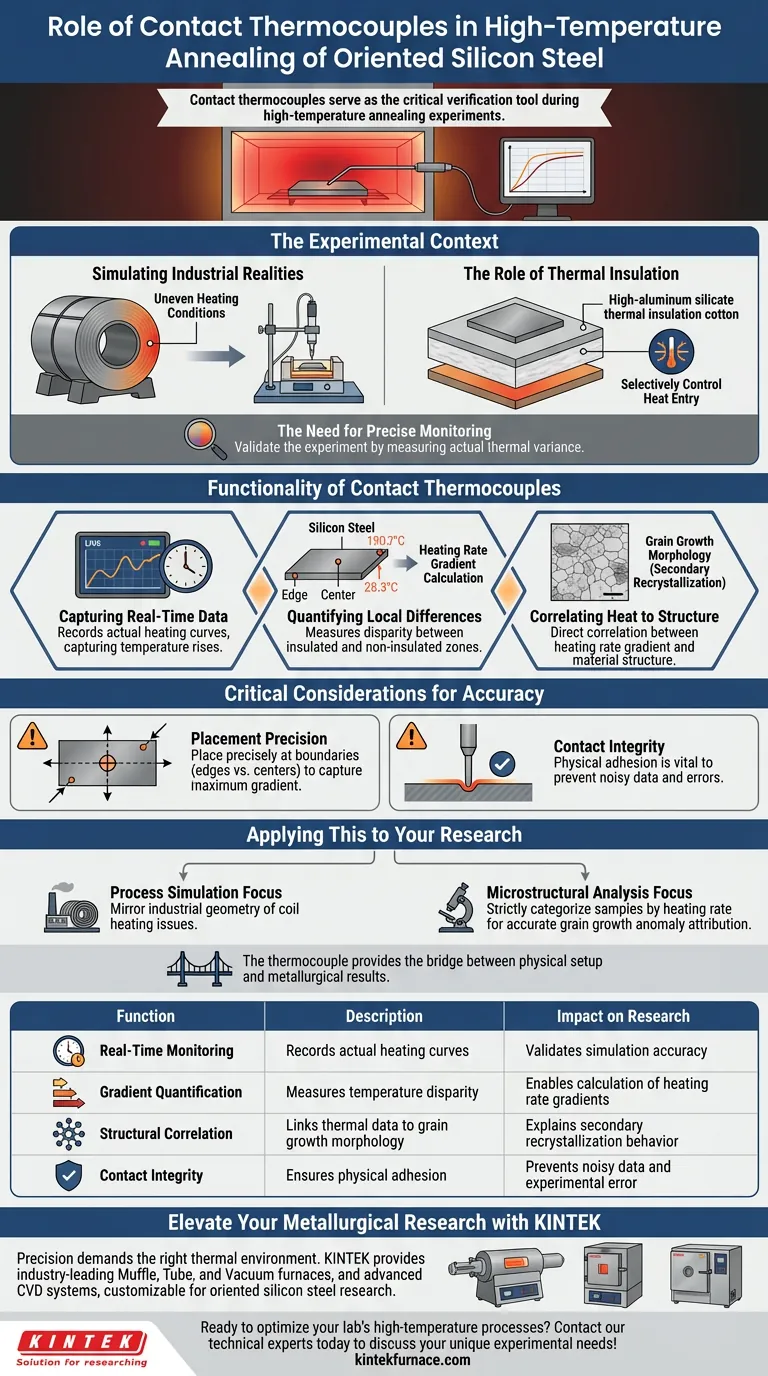

Contact thermocouples serve as the critical verification tool during high-temperature annealing experiments. They are positioned at specific coordinates on the oriented silicon steel sample—typically the edges and the center—to monitor and record the actual heating curves in real-time.

These devices transform a theoretical experiment into quantifiable data; they measure the precise local heating rate differences caused by thermal insulation, enabling researchers to link thermal gradients directly to grain growth behavior.

The Experimental Context

Simulating Industrial Realities

In industrial production, steel coils often experience uneven heating conditions.

To replicate this in a lab, researchers create an artificial gradient heat conduction environment.

The Role of Thermal Insulation

High-aluminum silicate thermal insulation cotton is applied to the steel samples.

By layering this cotton over specific areas, researchers can selectively control heat entry from different directions.

The Need for Precise Monitoring

While the insulation creates the potential for a gradient, you cannot assume the temperature distribution is accurate.

You must measure the actual thermal variance across the sample to validate the experiment.

Functionality of Contact Thermocouples

Capturing Real-Time Data

Thermocouples provide a live feed of the heating process.

They record the actual heating curves, capturing how temperature rises over time at different points on the steel.

Quantifying Local Differences

The primary function is to measure the disparity between the insulated and non-insulated zones.

By comparing data from the edges against the center, researchers can calculate the exact heating rate gradient.

Correlating Heat to Structure

The ultimate goal of this measurement is material analysis.

The data collected allows for a direct correlation between the heating rate gradient and the resulting grain growth morphology (specifically secondary recrystallization).

Critical Considerations for Accuracy

Placement Precision

The effectiveness of the experiment hinges on the exact positioning of the thermocouples.

They must be placed precisely at the boundaries of the insulated zones (edges vs. centers) to capture the maximum gradient.

Contact Integrity

Because these are contact thermocouples, physical adhesion to the sample is vital.

Poor contact during high-temperature annealing will result in noisy data, obscuring the subtle differences in heating rates that define the experiment.

Applying This to Your Research

If your primary focus is Process Simulation:

- Ensure thermocouples are placed to mirror the specific geometry of industrial coil heating issues you are trying to replicate.

If your primary focus is Microstructural Analysis:

- Use the thermocouple data to strictly categorize samples by heating rate, ensuring you attribute grain growth anomalies to the correct thermal history.

The thermocouple provides the bridge between the physical setup of the experiment and the metallurgical results you observe.

Summary Table:

| Function | Description | Impact on Research |

|---|---|---|

| Real-Time Monitoring | Records actual heating curves at edges and center. | Validates simulation accuracy. |

| Gradient Quantification | Measures temperature disparity between insulated and non-insulated zones. | Enables calculation of heating rate gradients. |

| Structural Correlation | Links thermal data to grain growth morphology. | Explains secondary recrystallization behavior. |

| Contact Integrity | Ensures physical adhesion during high-temp cycles. | Prevents noisy data and experimental error. |

Elevate Your Metallurgical Research with KINTEK

Precision in high-temperature annealing requires more than just insulation—it demands the right thermal environment. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnaces, alongside advanced CVD systems, all customizable to meet the rigorous demands of oriented silicon steel research. Backed by expert R&D and manufacturing, our systems ensure the thermal stability and precision necessary for accurate thermocouple data and grain growth analysis.

Ready to optimize your lab’s high-temperature processes? Contact our technical experts today to discuss your unique experimental needs!

Visual Guide

References

- Qian Gao, Bo Li. Effect of Gradient Heat Conduction on Secondary Recrystallization of Grain-Oriented Silicon Steel. DOI: 10.3390/met14020152

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is Alumina and how is it derived? Discover Its Role in Advanced Materials and Production

- Why is a vacuum pumping system essential for DD6 alloy and ceramic shell experiments? Achieve High-Purity Results

- What are the advantages of using a laboratory vacuum drying oven for modified ZnO nanomaterials? Protect Nano-Integrity

- What is the function of the circulating water cooling system? Optimize Pyrolysis Oil Condensation and Yield

- What are the key characteristics of the alumina furnace tube? Essential for High-Temp Lab Success

- Why is an alumina crucible used for vacuum carbothermal reduction? Ensure Purity at 1723 K

- What is the function of an alumina boat during high-temperature activation of porous carbon? Durable Lab Solutions

- Why is ceramic refractory material used in the freeboard area of a gasification reactor? Enhance Your Syngas Purity