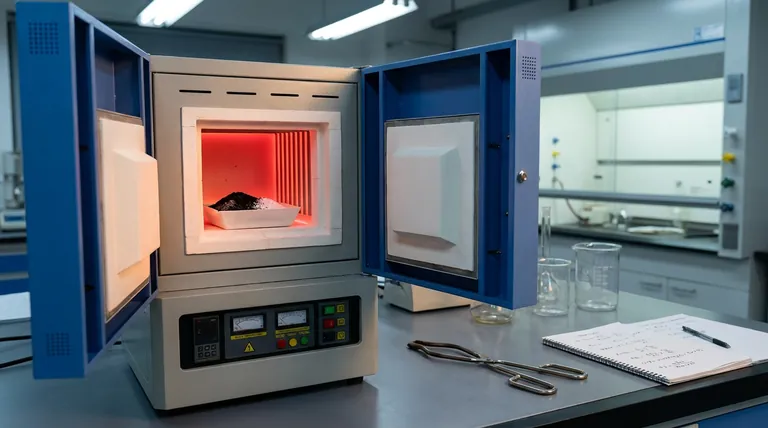

The primary function of an alumina boat is to act as an inert, high-strength reaction vessel that holds the mixture of chemical activating agents (such as potassium hydroxide) and carbon precursors within the furnace. It provides a stable physical barrier capable of withstanding temperatures up to 900 °C while resisting the highly corrosive nature of the molten activating agents. By preventing chemical interaction between the sample and the container, the alumina boat ensures the carbon structure transforms solely based on the intended activation parameters.

By maintaining structural integrity in harsh, corrosive environments, the alumina boat guarantees that the carbon activation process remains pure and uncontaminated. Its resistance to reaction prevents the vessel from degrading, thereby securing the precise development of the porous carbon structure.

The Critical Role of Material Stability

Withstanding Extreme Thermal Environments

High-temperature activation processes frequently require heating zones to reach approximately 900 °C.

Alumina (aluminum oxide) is selected for this task because of its exceptional thermal stability. It retains its mechanical strength and shape without softening or deforming under these intense thermal loads.

Resisting Chemical Erosion

The activation process often utilizes aggressive chemical agents, such as potassium hydroxide (KOH), to etch pores into the carbon.

At high temperatures, these agents transition into highly corrosive melts that would dissolve or degrade standard laboratory ceramics. The alumina boat provides the necessary chemical resistance to contain these corrosive melts safely for the duration of the reaction.

Ensuring Sample Purity and Quality

Preventing Cross-Contamination

A major risk during high-temperature synthesis is the reaction between the sample and its container.

Because the alumina boat remains chemically stable, it prevents the vessel material from leaching into or reacting with the carbonaceous precursors. This ensures that the synthesized porous carbon maintains high purity and is free from foreign contaminants derived from the boat itself.

Facilitating Consistent Pore Development

The ultimate goal of activation is to create a specific, controlled pore structure within the carbon.

By providing a neutral, non-reactive platform, the boat allows the furnace's thermal environment and the chemical activators to drive the etching process exclusively. This stability is essential for achieving a consistent specific surface area and pore size distribution.

Operational Considerations and Limitations

Vulnerability to Thermal Shock

While alumina is excellent at sustaining high temperatures, it can be brittle when subjected to rapid temperature changes.

Inserting or removing the boat from the furnace too quickly can cause thermal shock, leading to cracks or shattering. Users must heat and cool the vessel gradually to maintain its integrity.

Specific Chemical Compatibilities

Although alumina is highly resistant to the reducing atmospheres and alkaline activators (like KOH) used in carbon synthesis, it is not universally inert.

If your process involves different classes of highly acidic or fluorinated compounds, the chemical resistance of the boat must be re-evaluated to avoid degradation.

Making the Right Choice for Your Goal

To ensure successful porous carbon activation, select your vessel based on the specific demands of your thermal and chemical environment.

- If your primary focus is high-temperature durability (up to 900 °C): Rely on alumina boats to provide the necessary mechanical rigidity where other ceramic or glass materials would deform.

- If your primary focus is high-purity synthesis: Utilize high-grade alumina to prevent the corrosive activator melt from extracting impurities from the container wall into your sample.

Ultimately, the alumina boat is not merely a holder; it is a critical process safeguard that preserves the chemical fidelity of your carbon activation.

Summary Table:

| Feature | Benefit in Carbon Activation |

|---|---|

| Thermal Stability | Maintains structural integrity up to 900°C without deformation. |

| Chemical Resistance | Resists corrosive melts like KOH during the etching process. |

| High Purity | Prevents cross-contamination and leaching into the carbon sample. |

| Reliability | Ensures consistent pore size distribution and surface area. |

Elevate Your Material Synthesis with KINTEK Precision

Don't let vessel degradation compromise your research results. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance laboratory equipment, including specialized Muffle, Tube, Rotary, Vacuum, and CVD systems. Our high-temp furnaces and specialized labware are all customizable to meet your unique chemical compatibility and thermal requirements.

Whether you are synthesizing porous carbon or conducting complex heat treatments, KINTEK provides the durability and purity your lab demands. Contact us today to find the perfect high-temperature solution for your needs!

References

- Nawaf Albeladi, Robert Mokaya. Ultra-high surface area ionic-liquid-derived carbons that meet both gravimetric and volumetric methane storage targets. DOI: 10.1039/d3ee03957a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What considerations lead to the selection of a corundum crucible for CVD sulfurization? Ensure Peak Sample Purity

- What are some key terms related to Laboratory Furnaces? Demystify Types Like Muffle and Tube Furnaces

- Why is it necessary to use alumina or ceramic crucibles during the high-temperature evaporation of magnesium? Ensure Purity and Process Integrity

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What is the temperature resistance of alumina ceramic tubes? Up to 1800°C for Demanding Applications

- Why is zirconia grinding media preferred for NN-10ST ceramic powders? Ensure Purity & Dielectric Performance

- Why is graphite foil used to line graphite molds before loading titanium alloy powder? Ensure Purity and Protect Molds

- What role do ceramic crucibles play in the initial stages of coating? Ensure High-Purity Metal Melts Today