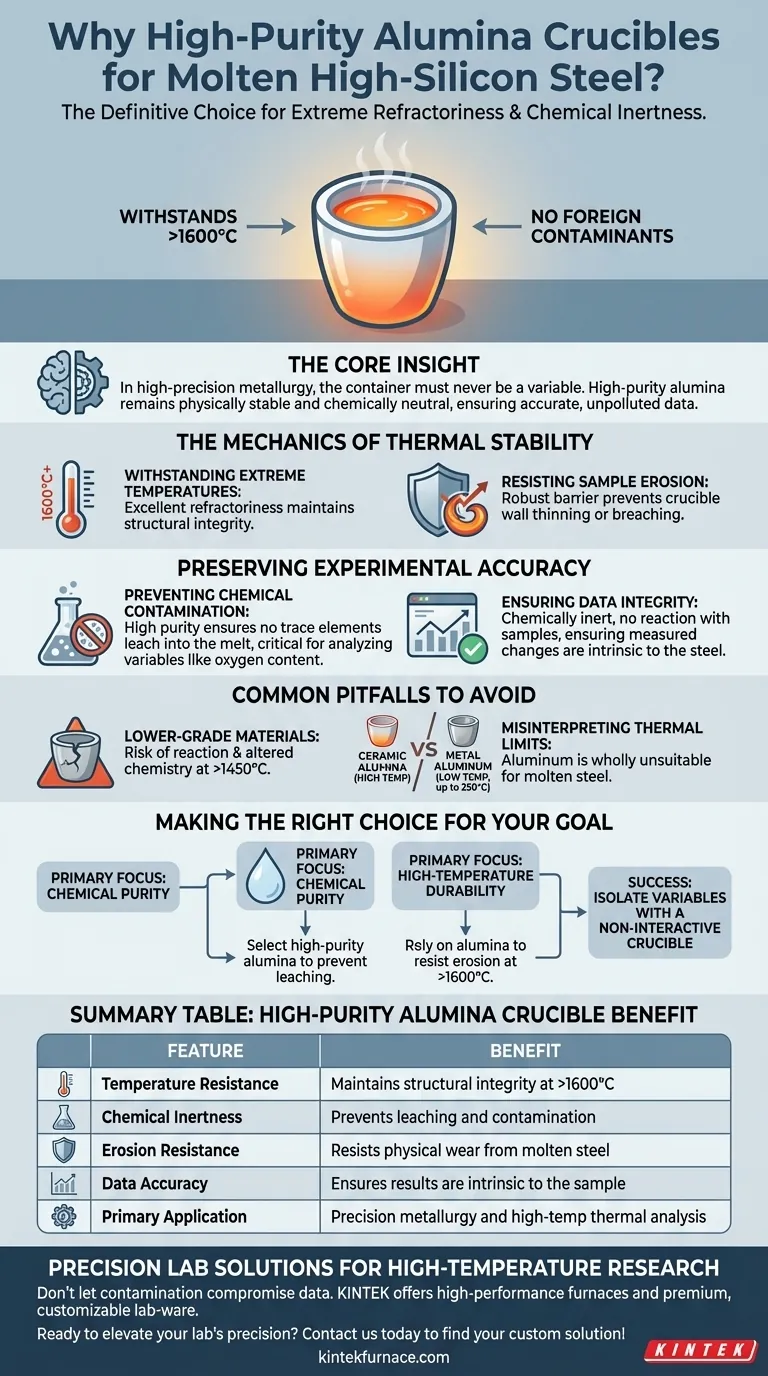

High-purity alumina crucibles are the definitive choice for containing molten high-silicon steel because they offer a critical combination of extreme refractoriness and chemical inertness. They specifically resist the erosive nature of steel melts at temperatures exceeding 1600°C while ensuring that no foreign contaminants compromise the alloy's composition.

The Core Insight In high-precision metallurgy, the container must never become a variable in the experiment. High-purity alumina is used because it remains physically stable and chemically neutral under extreme heat, ensuring that any data collected regarding the steel's thermophysical properties is accurate and unpolluted by the crucible itself.

The Mechanics of Thermal Stability

Withstanding Extreme Temperatures

Molten high-silicon steel experiments require thermal environments that would destroy standard laboratory ware. High-purity alumina exhibits excellent refractoriness, allowing it to maintain structural integrity at temperatures above 1600°C.

Resisting Sample Erosion

At these elevated temperatures, molten steel can be highly aggressive physically. Alumina crucibles provide a robust barrier that resists erosion from the melt. This stability prevents the crucible walls from thinning or breaching during the extended heating cycles required for experimental analysis.

Preserving Experimental Accuracy

Preventing Chemical Contamination

The primary danger in analyzing molten steel is the introduction of external impurities that skew the results. The "high purity" aspect of these alumina crucibles is not a luxury; it is a necessity.

By using high-purity material, you ensure that no trace elements leach from the crucible into the steel melt. This is particularly critical when analyzing the effects of specific variables, such as oxygen content, on the steel's properties.

Ensuring Data Integrity

When conducting thermal analysis (such as investigating thermophysical properties or sintering behaviors), the data must reflect the sample alone.

Because high-purity alumina is chemically inert, it does not react with the mineral samples or the steel melt. This ensures that measured heat changes or physical property shifts are intrinsic to the steel, rather than the byproduct of a reaction between the steel and its container.

Common Pitfalls to Avoid

The Risk of Lower-Grade Materials

Using crucibles with lower purity levels or different chemical compositions often leads to "interference." At temperatures >1450°C, inferior crucibles may react with the sample, altering the steel's chemistry and invalidating the data.

Misinterpreting Thermal Limits

It is vital to distinguish between ceramic alumina and metal aluminum crucibles. While aluminum crucibles are useful for low-temperature applications (up to 250°C) and offer high thermal conductivity, they are wholly unsuitable for molten steel. High-purity alumina is the only viable option for the extreme conditions of steel metallurgy.

Making the Right Choice for Your Goal

- If your primary focus is Chemical Purity: Select high-purity alumina to prevent trace elements from leaching into the melt and altering the steel's oxygen content analysis.

- If your primary focus is High-Temperature Durability: Rely on alumina for its ability to resist physical erosion and maintain structural integrity at temperatures exceeding 1600°C.

Success in high-temperature steel research depends on isolating your variables, starting with a crucible that refuses to interact with your sample.

Summary Table:

| Feature | High-Purity Alumina Crucible Benefit |

|---|---|

| Temperature Resistance | Maintains structural integrity at >1600°C |

| Chemical Inertness | Prevents leaching of trace elements and contamination |

| Erosion Resistance | Resists physical wear from aggressive molten steel melts |

| Data Accuracy | Ensures thermophysical results are intrinsic to the sample |

| Primary Application | Precision metallurgy and high-temperature thermal analysis |

Precision Lab Solutions for High-Temperature Research

Don’t let crucible contamination compromise your experimental data. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside premium lab-ware customizable for your unique needs. Whether you are analyzing molten steel or developing advanced materials, our high-purity solutions ensure your results remain accurate and unpolluted.

Ready to elevate your lab’s precision? Contact us today to find your custom solution!

Visual Guide

References

- Lukas Neubert, Olena Volkova. Effect of Oxygen on Thermophysical Properties of Molten High-Silicon Electrical Steels and Its Impact on Bubble Formation Behavior. DOI: 10.1007/s11663-025-03594-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the significance of using high-purity quartz tubes in MoS2 growth? Ensure High-Purity Crystal Synthesis

- Why are high-purity alumina crucibles selected as the substrate during the sintering of boron-containing stainless steel?

- What is the function of glass tubes in molten-core thermal drawing? Precision Shaping and Chemical Isolation

- How does a laboratory drying oven function in catalyst synthesis? Secure Precision Metal Precursor Stabilization

- What is the function of an alumina boat during high-temperature activation of porous carbon? Durable Lab Solutions

- What properties make quartz tubes ideal for heat treatment processes? Unlock High-Temperature Purity and Stability

- What is the recommended cooling rate for the alumina furnace tube? Prevent Thermal Shock and Extend Tube Life

- How do multi-bore high-purity alumina tubes stabilize CV tests? Enhance Data Accuracy with KINTEK Solutions