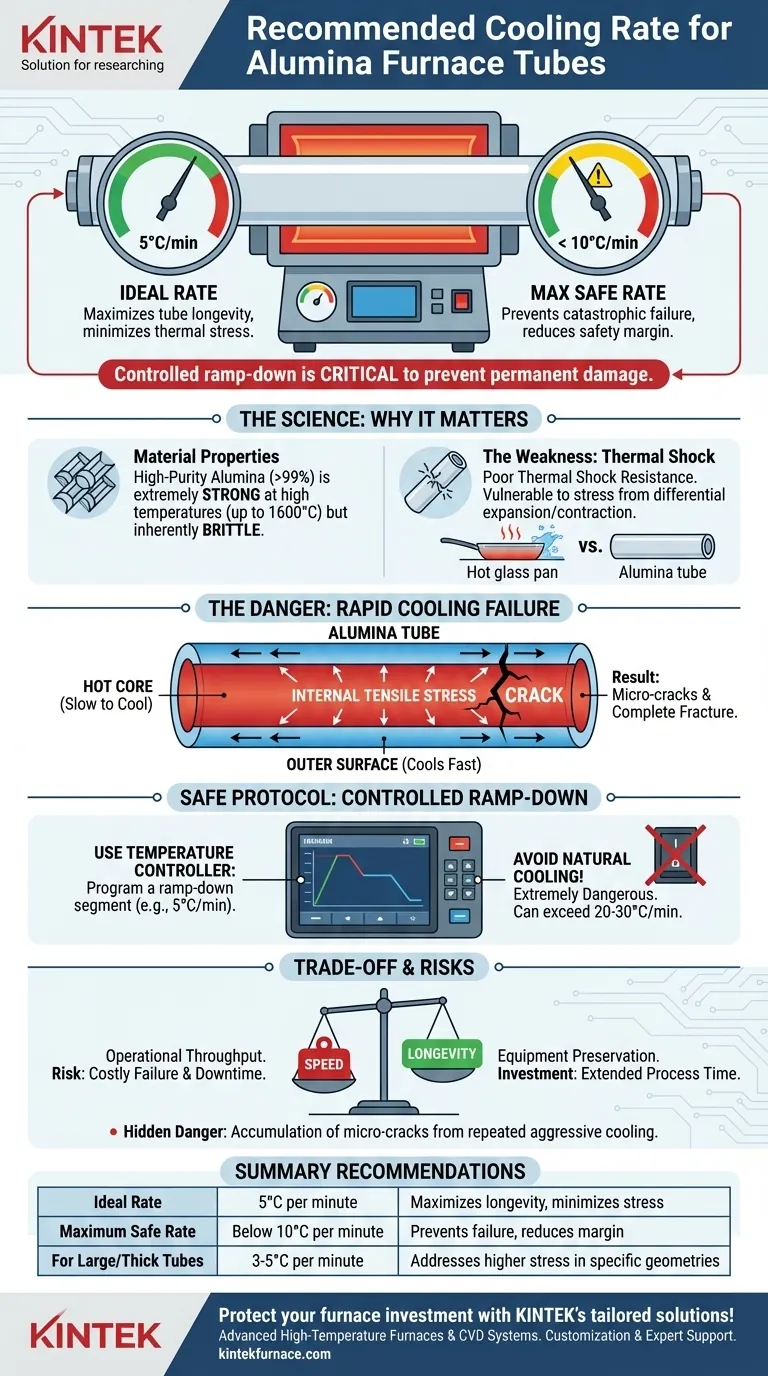

The recommended cooling rate for a high-purity alumina furnace tube is below 10°C per minute, with an ideal rate of 5°C per minute. This controlled ramp-down is not merely a suggestion but a critical procedure to prevent permanent damage to the ceramic. Abrupt temperature changes, such as those from natural cooling, will cause catastrophic failure.

The need for a slow, controlled cooling rate stems from a fundamental material property: high-purity alumina is extremely strong at high temperatures but is inherently brittle and highly susceptible to thermal shock. Ignoring this principle is the primary cause of cracked and failed furnace tubes.

The Science Behind the Cooling Rate: Understanding Thermal Shock

To operate a high-temperature furnace effectively, it is essential to understand the material limitations of its core components. The alumina tube is both the strength and the weak point of the system.

The Properties of High-Purity Alumina

High-purity alumina (>99%) is chosen for furnace tubes because of its exceptional performance at extreme temperatures, capable of continuous use up to 1600°C. It offers high chemical purity and stability, ensuring a non-reactive environment for sensitive processes.

Alumina's Inherent Weakness: Poor Thermal Shock Resistance

The primary vulnerability of this ceramic is its poor thermal shock resistance. Thermal shock is the stress induced in a material when different parts of it expand or contract at different rates due to rapid temperature changes.

Think of pouring cold water into a hot glass pan. The sudden contraction of the inner surface while the outer body remains hot creates immense stress, causing it to shatter. The same principle applies to an alumina furnace tube.

How Rapid Cooling Causes Failure

When a hot furnace is allowed to cool too quickly, the outer surface of the alumina tube cools and contracts faster than the insulated inner core.

This differential in contraction creates powerful internal tensile stresses. Because alumina is brittle, it cannot bend or stretch to accommodate this stress. Instead, the stress builds until it exceeds the material's strength, resulting in the formation of micro-cracks that quickly propagate into a complete fracture.

Implementing a Safe Cooling Protocol

A controlled cooling process is not optional; it is a mandatory operational step managed through the furnace's temperature control system.

The Role of the Temperature Controller

Your furnace's temperature controller is the tool you must use to manage this process. Modern controllers allow you to program multi-stage heating and cooling profiles. A "ramp-down" or "cooling" segment must be programmed to lower the temperature at the prescribed rate.

Why "Natural Cooling" is Unacceptable

Simply turning off the furnace power and allowing it to cool naturally is extremely dangerous for the alumina tube. This method can result in cooling rates of 20-30°C per minute or even faster, which is far beyond the material's tolerance. This is the most common and avoidable cause of tube failure.

Understanding the Trade-offs and Risks

While a slow cool-down cycle extends the overall process time, it is a necessary investment in the longevity and reliability of your equipment.

The Cost of Speed vs. The Cost of Failure

The primary trade-off is between operational throughput and equipment preservation. Attempting to save a few hours by accelerating the cooling phase introduces a significant risk of destroying a critical and expensive component, leading to costly downtime and replacement.

Signs of Thermal Stress Damage

Not all thermal shock damage is catastrophic. Repeated exposure to overly aggressive cooling cycles can cause an accumulation of micro-cracks. These invisible flaws weaken the tube over time, leading to an unexpected failure during a future thermal cycle, even one that is properly controlled.

Making the Right Choice for Your Process

Use your temperature controller to enforce a safe cooling profile based on your operational priorities and the physical constraints of your equipment.

- If your primary focus is maximum equipment longevity: Always program a conservative cooling rate of 5°C per minute or less, especially when operating near the tube's maximum temperature.

- If you are working with very large or thick-walled tubes: Use an even slower rate, such as 3-5°C per minute, as these geometries build up internal stress more readily.

- If your primary focus is process throughput: Acknowledge that cooling at a rate approaching 10°C per minute reduces your safety margin and increases the long-term risk of premature tube failure.

By respecting the material's physical limits, you ensure the integrity of your equipment and the reliability of your results.

Summary Table:

| Cooling Rate | Recommendation | Key Rationale |

|---|---|---|

| Ideal Rate | 5°C per minute | Maximizes tube longevity and minimizes thermal stress risk |

| Maximum Safe Rate | Below 10°C per minute | Prevents catastrophic failure but reduces safety margin |

| For Large/Thick Tubes | 3-5°C per minute | Addresses higher stress buildup in specific geometries |

Protect your furnace investment with KINTEK's tailored solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs, helping you avoid costly tube failures and enhance process reliability. Contact us today to discuss how we can optimize your lab's performance!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- Why are tubular furnaces important in material testing and research? Unlock Precision for Advanced Materials Development

- What materials are used for the tube chamber in tubular furnaces? Choose the Right Tube for Your Lab's High-Temp Needs

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More