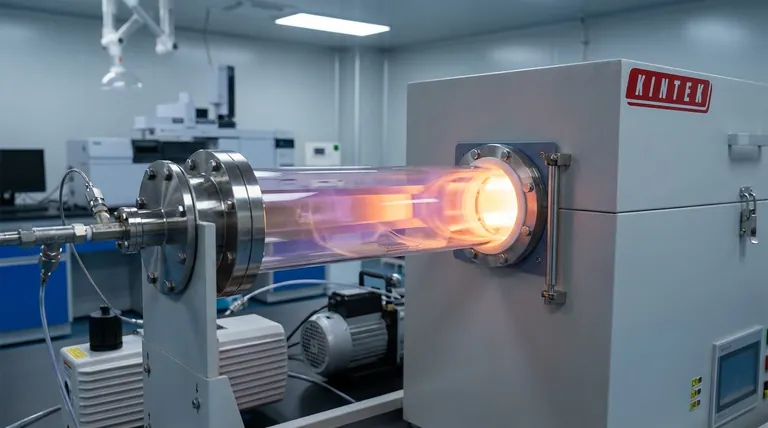

High-purity quartz tubes serve as the critical physical isolation barrier for the growth of Molybdenum Disulfide (MoS2). They function as a reaction vessel that withstands high-temperature corrosion while providing a sealed, vacuum, or controlled atmosphere. Crucially, their optical transparency allows for real-time visual monitoring of the reaction state, ensuring the process remains stable and observable.

The ultimate value of high-purity quartz lies in its ability to maintain an uncompromised "clean room" environment at the microscopic level. By combining extreme thermal stability with chemical inertness, it ensures that the structural integrity and electronic properties of the resulting MoS2 crystals remain free from impurities and oxidation.

Ensuring Chemical Integrity

Preventing Atmospheric Contamination

The primary function of the quartz tube is to isolate the MoS2 growth process from the external environment.

By effectively sealing the reaction, the tube prevents the infiltration of oxygen and moisture from the surrounding atmosphere. This is vital, as external contaminants can degrade the quality of the MoS2 layers during growth.

Maintaining Chemical Inertness

Beyond keeping outside air out, the vessel itself must not contaminate the sample.

High-purity quartz exhibits superior chemical stability, meaning it generally does not react with sulfides or sulfur vapors. This inertness ensures that impurities from the container walls do not leach into the reaction, preserving the purity of the MoS2 product.

Facilitating Vacuum Environments

MoS2 growth often requires vacuum flame-sealing or specific pressure controls.

Quartz tubes are robust enough to maintain these vacuum conditions, creating a dry, oxygen-free micro-environment. This prevents the volatilization or oxidation of precursor materials before the reaction is complete.

Withstanding Harsh Growth Conditions

High-Temperature Resilience

The synthesis of MoS2 typically involves significant heat.

High-purity quartz offers exceptional resistance to high temperatures, capable of withstanding environments exceeding 800°C. This allows the tube to endure the intense heat required for precursor sublimation and crystal formation without deforming or melting.

Resistance to Thermal Shock

Growth processes often involve rapid heating or cooling cycles (annealing).

Quartz has an extremely low coefficient of thermal expansion. This property allows the tube to undergo severe thermal cycling without cracking, ensuring the safety of the experiment and the integrity of the sample during cooling phases.

Enabling Real-Time Observation

Optical Transparency

Unlike ceramic or metal vessels, quartz provides excellent light transmission.

This transparency allows researchers to use external optical devices to monitor the reaction state directly through the furnace windows. Being able to observe ignition signals or deposition progress without breaking the seal is a significant advantage for process control.

Understanding the Trade-offs

Specific Chemical Interactions

While generally inert, quartz is not universally resistant to all conditions.

In specialized "active flux" synthesis techniques, the quartz wall can slowly erode to act as a silicon source. While this is useful for specific crystal growth methods, it can be a source of unintended contamination if your goal is pure MoS2 without silicon doping.

Physical Fragility

Despite their thermal robustness, quartz tubes remain brittle glass components.

They require careful handling during the loading and sealing processes. While they resist thermal shock well, they have low tolerance for mechanical impact compared to metallic alternatives.

Making the Right Choice for Your Goal

To maximize the effectiveness of your MoS2 growth setup, align the vessel's properties with your specific research objectives:

- If your primary focus is material purity: Prioritize the vacuum-sealing capabilities of the quartz to ensure an absolutely dry, oxygen-free environment that prevents cation oxidation.

- If your primary focus is process optimization: Leverage the tube's optical transparency to utilize high-speed cameras or optical sensors for in-situ monitoring of reaction kinetics.

High-purity quartz is the industry standard because it uniquely balances physical protection with optical accessibility.

Summary Table:

| Feature | Benefit for MoS2 Growth | Impact on Material Quality |

|---|---|---|

| Chemical Inertness | Prevents leaching from container walls | High electronic purity; no contamination |

| Vacuum Sealing | Isolates oxygen and moisture | Prevents oxidation and degradation |

| High Thermal Stability | Withstands temperatures >800°C | Maintains structural integrity during synthesis |

| Optical Transparency | Real-time visual monitoring | Precision control over reaction kinetics |

| Thermal Shock Resistance | Allows rapid heating/cooling | Prevents tube cracking during annealing |

Elevate Your Material Research with KINTEK

Precision MoS2 growth demands a controlled environment. KINTEK provides industry-leading thermal solutions, including CVD systems, vacuum furnaces, and customizable tube furnaces designed to work seamlessly with high-purity quartz reaction chambers.

Backed by expert R&D and advanced manufacturing, our systems are tailored to your unique lab requirements, ensuring uncompromised purity and repeatable results for your 2D material synthesis.

Ready to optimize your growth process? Contact KINTEK today for a custom solution!

References

- Effects of Reaction Temperature and Catalyst Type on Fluid Catalytic Cracking (FCC) of Crude Oil Feeds: A Microactivity Test Unit Study. DOI: 10.64589/juri/207996

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is a covered aluminum crucible necessary for g-C3N5 thermal polycondensation? Optimize Your Synthesis Atmosphere

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- How does the SOM method enhance titanium alloy purity? The Power of Solid Electrolyte Tubes

- How does the hardness of alumina ceramics compare to other materials? Discover Its Superior Wear Resistance

- How does a vacuum pump facilitate the pre-treatment of modified multi-walled carbon nanotubes? Optimize Surface Activation

- What mechanical properties should be evaluated for alumina ceramic furnace tubes? Ensure Durability and Performance

- How does a laboratory vacuum system contribute to high-purity high-entropy alloys? Essential Insights

- Why is a graphite thermal baffle necessary for thermal field control? Master Single-Crystal Growth Quality