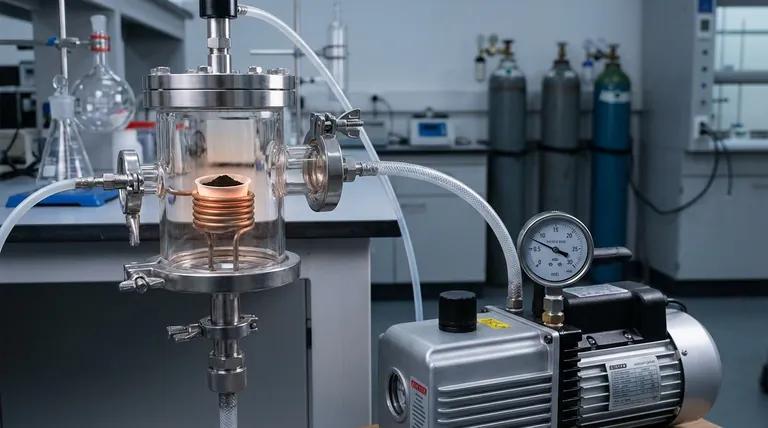

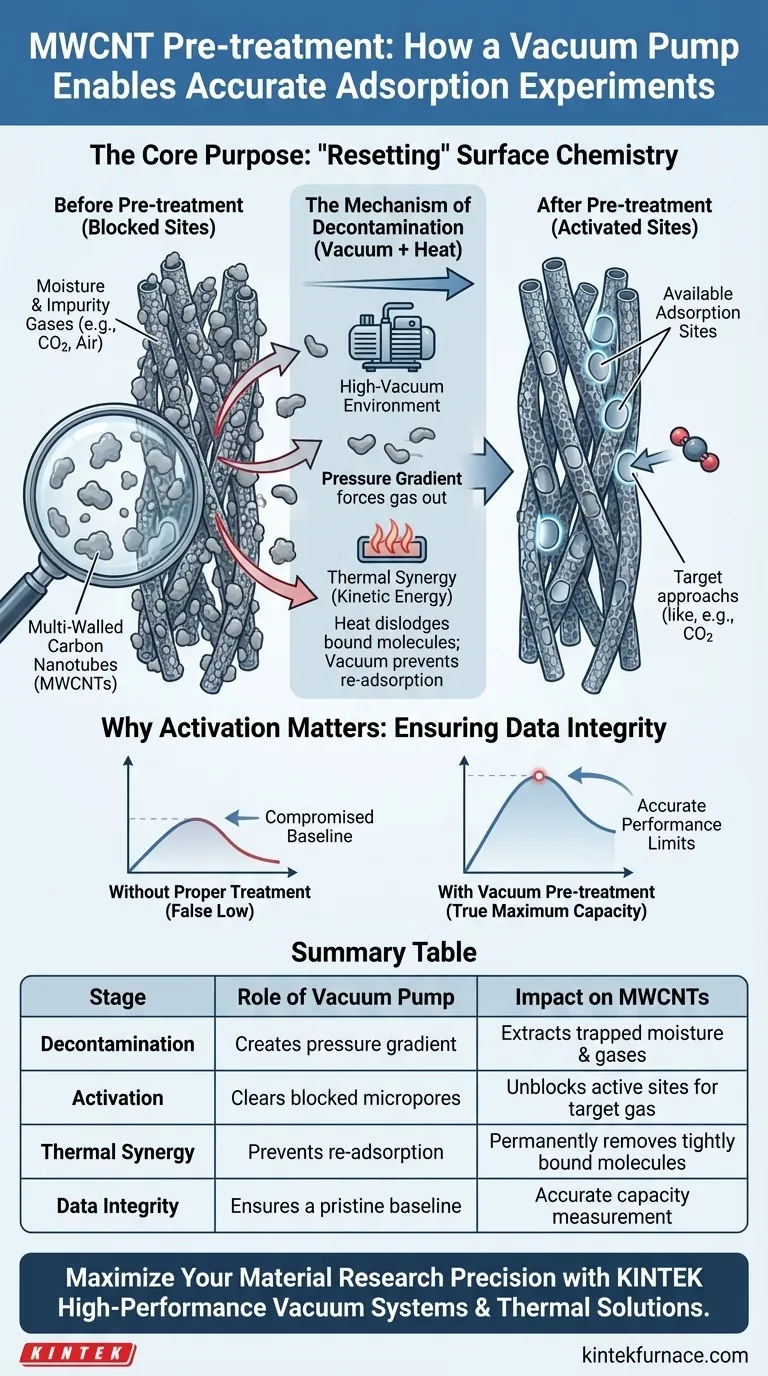

A vacuum pump facilitates pre-treatment by creating the high-vacuum environment necessary for effective degassing. Used in conjunction with a heating system, the pump extracts residual moisture and impurity gases deeply trapped within the micropores of modified multi-walled carbon nanotubes (MWCNTs). This clearing process is a prerequisite for accurate adsorption experiments.

The core purpose of this pre-treatment is to "reset" the material's surface chemistry. By stripping away pre-adsorbed contaminants, the process activates adsorption sites, ensuring that your data reflects the material's true maximum capacity rather than a compromised baseline.

The Mechanism of Decontamination

To understand why a vacuum pump is essential, you must look at the microscopic structure of MWCNTs. Their high surface area acts as a magnet for atmospheric contaminants that must be removed before testing.

Establishing the Pressure Gradient

The vacuum pump reduces the pressure surrounding the sample significantly.

This creates a strong pressure gradient between the internal pores of the nanotubes and the external environment. This differential forces gas molecules trapped inside the material to diffuse outward, where they are evacuated by the pump.

Removal of Specific Impurities

Without vacuum treatment, MWCNTs act as sponges for environmental "noise."

The vacuum pump specifically targets residual moisture and impurity gases (such as pre-adsorbed CO2 or air molecules). These substances physically block the pores, preventing the target gas from interacting with the material during the actual experiment.

Thermal Synergy

While the vacuum lowers pressure, the process is almost always paired with a heating system.

The heat provides the kinetic energy required to dislodge tightly bound molecules, while the vacuum pump prevents them from re-adsorbing. This combination ensures a thorough cleaning of the micropores.

Why "Activation" Matters

The pre-treatment process is often described as activating the material. This is not about changing the material's chemical structure, but about making its existing features available.

Unblocking Active Sites

Modified MWCNTs contain specific active sites designed to capture target molecules (like carbon dioxide).

If these sites are occupied by moisture or atmospheric gases, they are chemically unavailable. The vacuum pump clears these blockages, maximizing the availability of adsorption sites.

Ensuring Data Integrity

The ultimate goal of using a vacuum pump is data reliability.

If impurities remain, the experiment will yield a false low for adsorption capacity. By ensuring a pristine surface state, the vacuum pump guarantees that measured values represent the material's actual performance limits.

Understanding the Trade-offs

While vacuum degassing is critical, it is important to recognize potential sources of error in the process.

The Risk of Incomplete Degassing

Simply running a vacuum pump is not enough; the depth and duration of the vacuum matter.

If the vacuum is insufficient or applied for too short a time, deep-seated impurities may remain in the micropores. This results in "ghost" occupancy that skews repeatability and accuracy.

Thermal Limits

While heat assists the vacuum, excessive temperature during degassing can degrade surface modifications.

You must balance the need for impurity removal with the thermal stability of the specific modifications made to the MWCNTs.

Making the Right Choice for Your Experiment

To ensure your adsorption data is valid, tailor your pre-treatment approach to your specific experimental goals.

- If your primary focus is Maximum Capacity: Prioritize a high-vacuum environment to remove every trace of moisture, as this ensures you measure the true upper limit of CO2 uptake.

- If your primary focus is Repeatability: Establish a rigid, standardized protocol for vacuum pressure and duration to ensure every sample starts from the exact same "clean" state.

Reliable adsorption data begins with a pristine surface, and a high-performance vacuum pump is the only tool that can guarantee it.

Summary Table:

| Stage of Pre-treatment | Role of Vacuum Pump | Impact on MWCNTs |

|---|---|---|

| Decontamination | Creates pressure gradient | Extracts trapped moisture and atmospheric impurity gases |

| Activation | Clears blocked micropores | Unblocks active sites to maximize target gas uptake |

| Thermal Synergy | Prevents re-adsorption | Works with heat to permanently remove tightly bound molecules |

| Data Integrity | Ensures a pristine baseline | Eliminates 'false low' results for accurate capacity measurement |

Maximize Your Material Research Precision with KINTEK

Precise adsorption data starts with a pristine surface. KINTEK provides the high-performance vacuum systems and thermal processing solutions essential for the effective degassing of MWCNTs and other advanced materials.

Backed by expert R&D and manufacturing, we offer a comprehensive range of lab equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your unique experimental parameters.

Ready to elevate your lab's efficiency and data reliability? Contact our specialists today to find your custom solution!

Visual Guide

References

- Zohreh Khoshraftar, Alireza Hemmati. Comprehensive investigation of isotherm, RSM, and ANN modeling of CO2 capture by multi-walled carbon nanotube. DOI: 10.1038/s41598-024-55836-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does choosing alumina vs graphite crucibles affect Al-Si melting? Expert Guide to Data Integrity

- Why use alumina crucibles for NaNbO3:Pr3+ annealing? Ensure High Purity and Thermal Stability

- What is the function of high-purity graphite crucibles in Al-Cu-Mn master alloy prep? Ensure Chemical Purity

- What role does a high-precision mass flow controller play in assessing the gas selectivity of Gallium Sulfide sensors?

- What role does a covered alumina or aluminum alloy crucible play in g-C3N4 synthesis? Maximize Yield and Quality

- Why are ceramic crucibles required for the high-temperature calcination of dolomite? Ensure High-Purity Results

- What are the primary functions of high-purity graphite molds in SPS? Optimize Your Spark Plasma Sintering Process

- What is the function of an alumina boat during high-temperature activation of porous carbon? Durable Lab Solutions