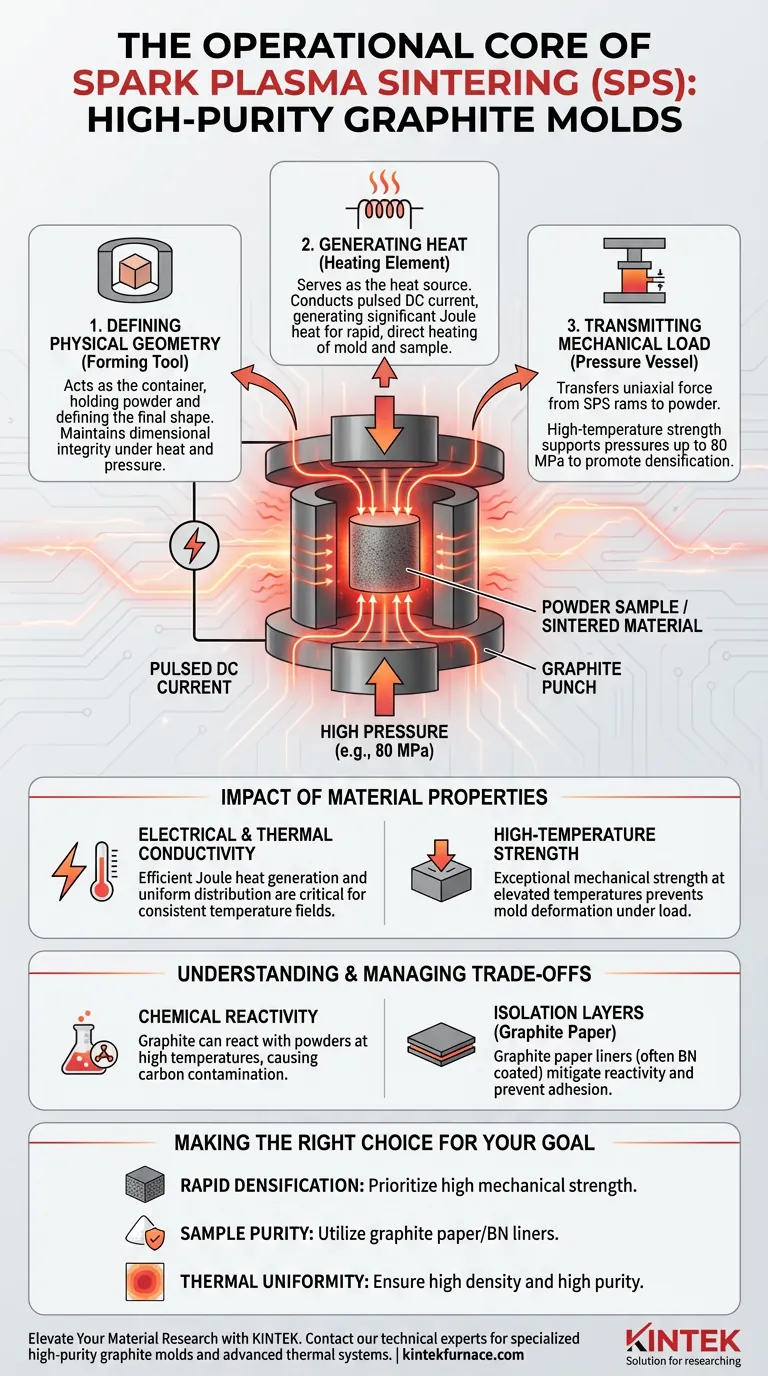

High-purity graphite molds function as the operational core of the Spark Plasma Sintering (SPS) process. They perform three distinct, simultaneous roles: defining the physical geometry of the sample, serving as the electrical heating element to generate Joule heat, and acting as the mechanical vessel to transmit high pressure directly to the powder.

By integrating the roles of a forming die, a resistive heater, and a pressure chamber into a single component, high-purity graphite molds enable the synchronized application of thermal and mechanical energy. This unique multifunctionality is the driving force behind the ability of SPS to achieve rapid densification and precise microstructural control.

The Three Primary Functions

The effectiveness of SPS relies on the mold's ability to multitask under extreme conditions. The graphite mold is not merely a passive container; it is an active participant in the sintering physics.

1. Defining Physical Geometry (The Forming Tool)

At its most basic level, the graphite mold acts as the forming tool or die. It serves as the container that holds the loose powder and defines the final physical shape of the sintered sample.

This function requires the mold to maintain its dimensional integrity throughout the process. It ensures that the loose powder is confined to a specific volume before and during the densification phase.

2. Generating Heat via Conductivity (The Heating Element)

Unlike conventional sintering, where external heaters warm a chamber, the graphite mold in SPS serves as the heat source itself. It acts as a conductive medium that allows thousands of amperes of pulsed DC current to pass through it.

Because graphite is electrically conductive but possesses resistance, this current generates significant Joule heat. This enables direct, rapid heating of both the mold and the sample inside, facilitating the high heating rates characteristic of SPS.

3. Transmitting Mechanical Load (The Pressure Vessel)

The third function is mechanical. The mold serves as a pressure transmission medium, transferring external uniaxial loads from the SPS machine's rams directly to the powder particles.

Graphite's high-temperature mechanical strength allows it to withstand significant pressures (often between 60 MPa and 80 MPa) even at sintering temperatures (e.g., 823 K and above). This pressure promotes plastic flow and atomic diffusion, which are essential for achieving high material density.

The Impact of Material Properties

The performance of the mold is directly tied to the specific properties of the high-purity graphite used.

Electrical and Thermal Conductivity

High electrical conductivity ensures the efficient generation of Joule heat. Simultaneously, high thermal conductivity ensures that this heat is distributed uniformly throughout the mold and the sample.

Variations in graphite density or purity can lead to uneven temperature fields. This non-uniformity can result in defective samples with inconsistent microstructures.

High-Temperature Strength

The graphite must possess exceptional mechanical strength at elevated temperatures. If the graphite is too weak, it will deform or fracture under the mechanical load required to densify the ceramic or metallic powder.

Understanding the Trade-offs

While high-purity graphite is the standard for SPS, it introduces specific challenges that must be managed to ensure sample quality.

Chemical Reactivity and Contamination

At high temperatures, graphite can react chemically with certain powders. This can lead to carbon contamination of the sample surface or the formation of unwanted carbides.

Furthermore, the sample may adhere to the mold walls, making removal difficult and potentially damaging the sample.

The Necessity of Isolation Layers

To mitigate reactivity and adhesion, graphite paper is frequently used as an interface liner.

Typically coated with boron nitride, this paper acts as an isolation layer between the powder and the mold. It prevents chemical reactions and adhesion while maintaining the necessary electrical and thermal continuity.

Making the Right Choice for Your Goal

The selection and setup of your graphite mold should be tailored to your specific sintering objectives.

- If your primary focus is rapid densification: Prioritize graphite with high mechanical strength to maximize the pressure application (up to 80 MPa) without mold failure.

- If your primary focus is sample purity: Always utilize graphite paper liners, potentially with boron nitride coatings, to prevent carbon diffusion and adhesion.

- If your primary focus is thermal uniformity: Ensure the graphite mold has high density and high purity to guarantee consistent electrical resistance and thermal conduction paths.

Ultimately, the graphite mold determines the upper limits of pressure and heating rate your SPS process can achieve.

Summary Table:

| Function | Role in SPS Process | Benefit for Material Production |

|---|---|---|

| Forming Die | Defines physical geometry | Ensures dimensional accuracy and powder confinement |

| Heating Element | Generates Joule heat via pulsed DC | Enables ultra-fast heating rates and energy efficiency |

| Pressure Vessel | Transmits uniaxial mechanical load | Promotes plastic flow and high-density sintering |

| Conductive Medium | Distributes thermal/electrical energy | Ensures uniform microstructures and material consistency |

Elevate Your Material Research with KINTEK

Unlock the full potential of your Spark Plasma Sintering (SPS) applications with high-performance components. Backed by expert R&D and precision manufacturing, KINTEK offers specialized high-purity graphite molds and advanced thermal systems, including Muffle, Tube, Rotary, Vacuum, and CVD furnaces, all fully customizable to your unique research or production needs.

Ready to achieve superior density and microstructural control?

Contact our technical experts today to discuss your project

Visual Guide

References

- Mohamed Salaheldeen, А. Zhukov. Dependence of Magnetic Properties of As-Prepared Nanocrystalline Ni2MnGa Glass-Coated Microwires on the Geometrical Aspect Ratio. DOI: 10.3390/s24113692

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why is molybdenum (Mo) selected as the crucible material for the evaporation of NiO-doped Ga2O3? Expert Insights

- Why is a quartz reaction tube ideal for tubular carbon nanofibers? High-Purity Synthesis Solutions

- What are the functions of a high vacuum mechanical pump in Ga2O3 PETO? Ensure Purity in Film Preparation

- What are the considerations for using high-purity alumina crucibles or boats for SrVO3 sintering? Best Practices

- Why are high-purity alumina crucibles used for LLZO sintering? Master Lithium Volatility Control

- Why Is a High-Precision Heating and Stirring Platform Necessary for ZnO Sol-Gel Synthesis? Achieve Perfect Nanoparticles

- Why is a high-precision mass flow controller (MFC) necessary in ferronickel alloy smelting? Ensure Metal Purity

- Why is a high-purity alumina (Al2O3) crucible required for the melting of nickel-based superalloys?