High-precision Mass Flow Controllers (MFCs) are indispensable in ferronickel alloy smelting because they strictly regulate the protective gas environment required for the process. By accurately controlling the flow of inert gases like argon, they maintain a stable atmosphere that is crucial for chemical consistency and metal purity.

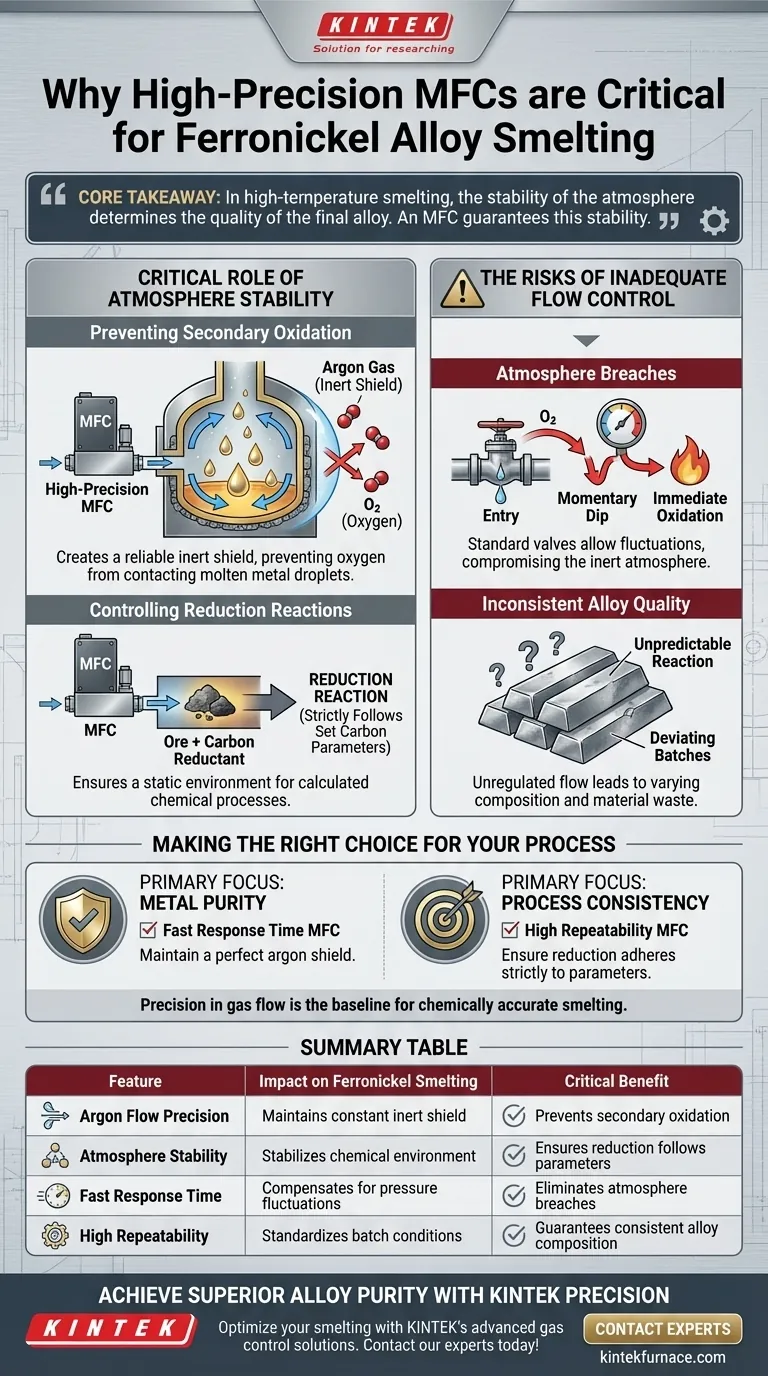

Core Takeaway In high-temperature smelting, the stability of the atmosphere determines the quality of the final alloy. An MFC guarantees this stability, preventing the re-oxidation of molten metal and ensuring that critical carbon reduction reactions proceed exactly as calculated.

The Critical Role of Atmosphere Stability

The smelting process is not just about heat; it is about precise chemical control. The primary function of an MFC in this context is to act as the guardian of the furnace's atmosphere.

Preventing Secondary Oxidation

At the extreme temperatures required for smelting, metal droplets become highly reactive. Without a protective barrier, they are susceptible to secondary oxidation.

This occurs when the metal reacts with oxygen in the environment, effectively reversing the smelting process and degrading the quality of the alloy.

An MFC ensures a constant, precise flow of argon gas into the furnace. This creates a reliable inert shield that prevents oxygen from contacting the molten metal droplets.

Controlling Reduction Reactions

Ferronickel smelting relies on a reduction reaction, where a carbon reductant removes oxygen from the ore to isolate the metal.

This reaction is calculated based on specific set parameters. If the gas environment fluctuates, the reaction conditions destabilize.

A high-precision MFC ensures the environment remains static, forcing the reduction reaction to occur strictly according to the set carbon parameters. This guarantees the chemical process matches the theoretical calculations.

The Risks of Inadequate Flow Control

While high-precision MFCs represent an investment, it is vital to understand the operational risks of using inferior control methods.

Atmosphere Breaches

Standard valves or low-precision meters often allow for minor fluctuations in gas pressure or flow rate.

In many industries, this is acceptable. In ferronickel smelting, even a momentary dip in argon flow can compromise the inert atmosphere, leading to immediate oxidation of the product.

Inconsistent Alloy Quality

If the flow of gas is not strictly regulated, the reduction reaction becomes unpredictable.

This leads to batches that deviate from the intended carbon parameters, resulting in inconsistent alloy composition and potential material waste.

Making the Right Choice for Your Process

When designing or upgrading a smelting furnace, the choice of flow control must align with your metallurgical goals.

- If your primary focus is Metal Purity: Prioritize an MFC with fast response times to maintain a perfect argon shield and prevent secondary oxidation.

- If your primary focus is Process Consistency: Select an MFC with high repeatability to ensure the reduction reaction adheres strictly to your carbon parameters every time.

Precision in gas flow is not a luxury; it is the baseline requirement for chemically accurate smelting.

Summary Table:

| Feature | Impact on Ferronickel Smelting | Critical Benefit |

|---|---|---|

| Argon Flow Precision | Maintains a constant inert shield | Prevents secondary oxidation of droplets |

| Atmosphere Stability | Stabilizes chemical environment | Ensures reduction follows carbon parameters |

| Fast Response Time | Compensates for pressure fluctuations | Eliminates atmosphere breaches |

| High Repeatability | Standardizes batch conditions | Guarantees consistent alloy composition |

Achieve Superior Alloy Purity with KINTEK Precision

Don't let atmosphere fluctuations compromise your smelting quality. KINTEK provides high-performance gas control solutions integrated with our advanced laboratory equipment. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for high-temperature metallurgy and precise chemical control.

Ready to optimize your smelting process? Contact our technical experts today to find the perfect high-precision solution for your unique needs!

Visual Guide

References

- Erdenebold Urtnasan, Jei‐Pil Wang. Relationship Between Thermodynamic Modeling and Experimental Process for Optimization Ferro-Nickel Smelting. DOI: 10.3390/min15020101

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Ultra High Vacuum CF Flange Stainless Steel Sapphire Glass Observation Sight Window

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the purpose of cleaning MgO substrates for ScN growth? Optimize Your Epitaxial Film Quality

- What is the primary function of graphitized quartz glass tubes in the synthesis of Bi2Se3-Nd2Se3 alloys?

- How does a laboratory blast drying oven facilitate the treatment of Au/ZnO/In2O3 precursor precipitates? Key Benefits

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What is the function of a graphite crucible in iron ore softening tests? Simulate Blast Furnace Conditions Perfectly

- Why is a high-purity graphite crucible preferred for (AgCu)0.999Te0.69Se0.3S0.01 preparation? Ensure Peak Purity.

- Why is the use of high-purity graphite crucibles essential? Protect TiC-High Manganese Steel During Sintering

- How does a laboratory drying oven ensure the structural stability of microcapsule granules? Expert Drying Guide