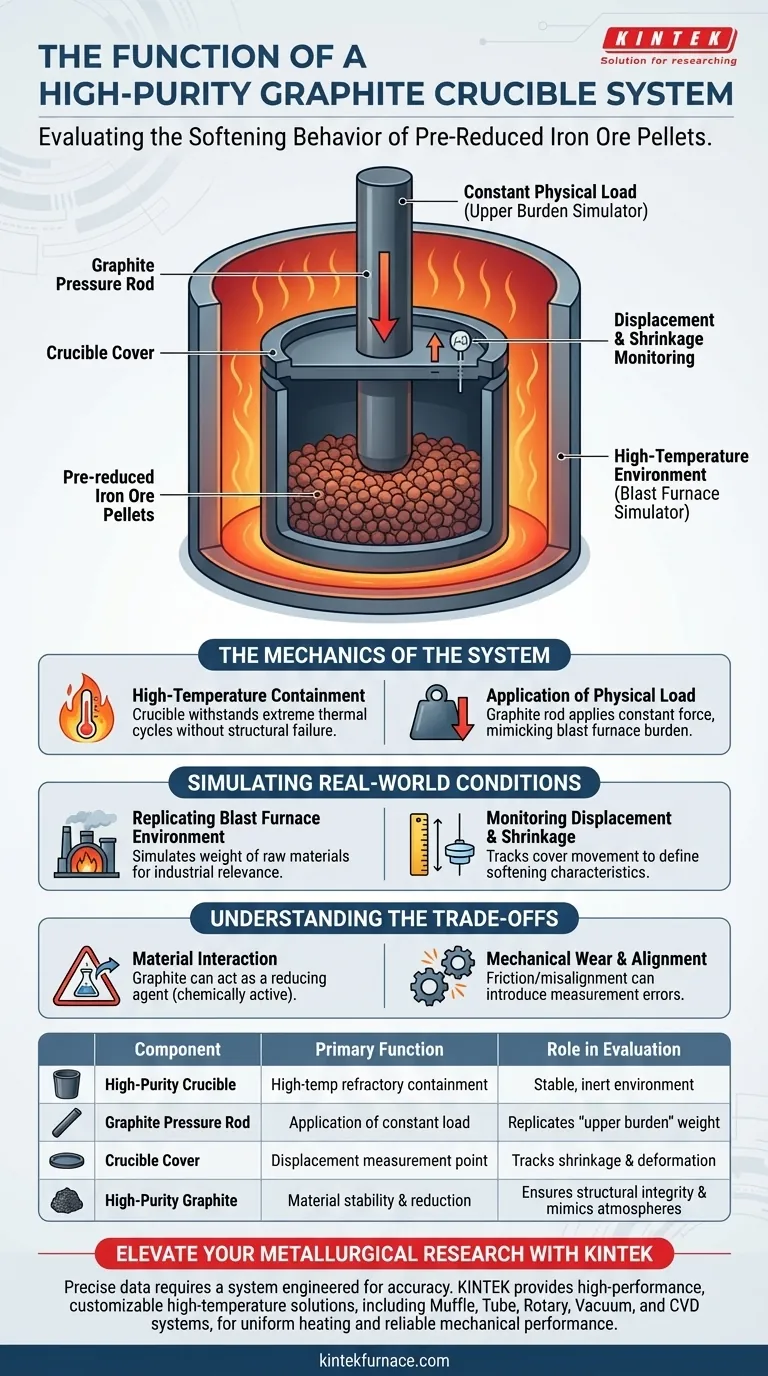

The primary function of a high-purity graphite crucible system in this context is to act as a dynamic testing vessel that simulates the mechanical and thermal conditions of a blast furnace. It does not merely hold the sample; combined with a pressure rod and cover, it applies a constant physical load to pre-reduced iron ore pellets to measure their deformation and shrinkage during heating.

The system serves as a mechanical simulator rather than a passive container. By applying a constant load via a graphite pressure rod, it replicates the weight of the "upper burden" in a blast furnace, allowing researchers to quantify exactly when and how pellets soften under operational pressure.

The Mechanics of the System

High-Temperature Containment

The fundamental role of the crucible is to serve as a refractory container.

It must withstand the extreme thermal cycles associated with heating and reducing iron ore without melting or structurally failing.

High-purity graphite is selected for its excellent high-temperature stability, ensuring the vessel remains intact while the contents inside undergo significant phase changes.

Application of Physical Load

Unlike standard melting crucibles, this system includes a graphite pressure rod and cover.

This assembly is designed to exert a controlled, constant physical force onto the iron ore pellets.

This mechanical loading is critical because iron ore pellets behave differently under compression than they do when heated freely.

Simulating Real-World Conditions

Replicating the Blast Furnace Environment

The goal of this apparatus is to mimic the internal environment of a blast furnace.

In an actual furnace, pellets are subjected to the immense weight of the raw materials (the burden) stacked above them.

The graphite system simulates this "upper burden" pressure, providing data that is directly relevant to industrial ironmaking operations.

Monitoring Displacement and Shrinkage

The system allows for the precise measurement of the displacement of the graphite cover.

As the pellets heat up, reduce, and eventually soften, they shrink or deform, causing the cover to move.

By tracking this movement, researchers can calculate the shrinkage rate and define the softening characteristics of the ore with high accuracy.

Understanding the Trade-offs

Material Interaction

While graphite offers stability, it is chemically active (composed of Carbon).

In high-temperature metallurgy, graphite can act as a reducing agent or interact with the sample material.

While this aids in simulating the reducing atmosphere of a blast furnace, it requires researchers to distinguish between effects caused by the gas atmosphere and those caused by contact with the crucible walls.

Mechanical Wear and Alignment

The system relies on moving parts (the rod and cover) operating at extreme temperatures.

Friction or misalignment between the pressure rod and the crucible can introduce measurement errors regarding displacement.

High-purity manufacturing is essential to ensure smooth operation and prevent mechanical binding during the expansion and contraction cycles.

Making the Right Choice for Your Goal

When designing experiments or selecting equipment for iron ore characterization, consider your specific objectives:

- If your primary focus is Industrial Simulation: Ensure the pressure applied by the graphite rod accurately calculates to the specific burden height of the blast furnace you are modeling.

- If your primary focus is Data Accuracy: Regularly calibrate the displacement sensors and inspect the graphite components for surface wear to prevent friction from skewing shrinkage data.

Accurate softening data relies on treating the crucible system as a precision instrument, not just a heat-resistant cup.

Summary Table:

| Component | Primary Function | Role in Evaluation |

|---|---|---|

| High-Purity Crucible | High-temp refractory containment | Provides a stable, inert environment for phase changes. |

| Graphite Pressure Rod | Application of constant load | Replicates the "upper burden" weight of a blast furnace. |

| Crucible Cover | Displacement measurement point | Facilitates tracking of pellet shrinkage and deformation. |

| High-Purity Graphite | Material stability & reduction | Ensures structural integrity and mimics reducing atmospheres. |

Elevate Your Metallurgical Research with KINTEK

Precise data on iron ore softening behavior requires more than just heat; it demands a system engineered for accuracy and durability. KINTEK provides high-performance lab high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all backed by expert R&D and manufacturing.

Whether you need standard crucibles or customizable high-purity graphite systems tailored to your specific blast furnace simulation needs, our equipment ensures uniform heating and reliable mechanical performance.

Ready to optimize your material characterization? Contact KINTEK today to discover how our customizable high-temperature solutions can enhance your laboratory's efficiency and data precision.

Visual Guide

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the temperature range for Laboratory Type Furnaces? Find Your Ideal Heat Solution

- Why introduce argon flow into a steel crucible for ZK51A alloy? Ensure Safety and High-Purity Melting

- Why are flexible graphite gaskets utilized for sealing in LiF-BeF2 molten salt experiments? High-Resilience Solutions

- What type of pump is used in water circulating vacuum pumps and how is it installed? Discover Robust Fluid-Based Vacuum Solutions

- What cost factors should be considered when choosing an alumina ceramic furnace tube? Optimize Total Cost of Ownership

- Why are lidded alumina crucibles required for LLZO sintering? Ensure High Ionic Conductivity and Phase Purity

- How is a precision gas flow control system configured for calcium carbonate decomposition? Master Industrial Kinetics

- What role do ceramic crucibles play in the initial stages of coating? Ensure High-Purity Metal Melts Today