At its core, a circulating water vacuum pump is a type of liquid ring vacuum pump. It functions as a centrifugal mechanical pump that ingeniously uses a ring of circulating water as its primary working fluid. This design creates a vacuum by forming a series of "liquid pistons" instead of mechanical ones, making it exceptionally robust for laboratory and industrial applications.

The central principle is not complex machinery, but fluid dynamics. The pump uses a spinning impeller to create a ring of water that seals and compresses gas, providing both a vacuum source and a cooling mechanism in a single device.

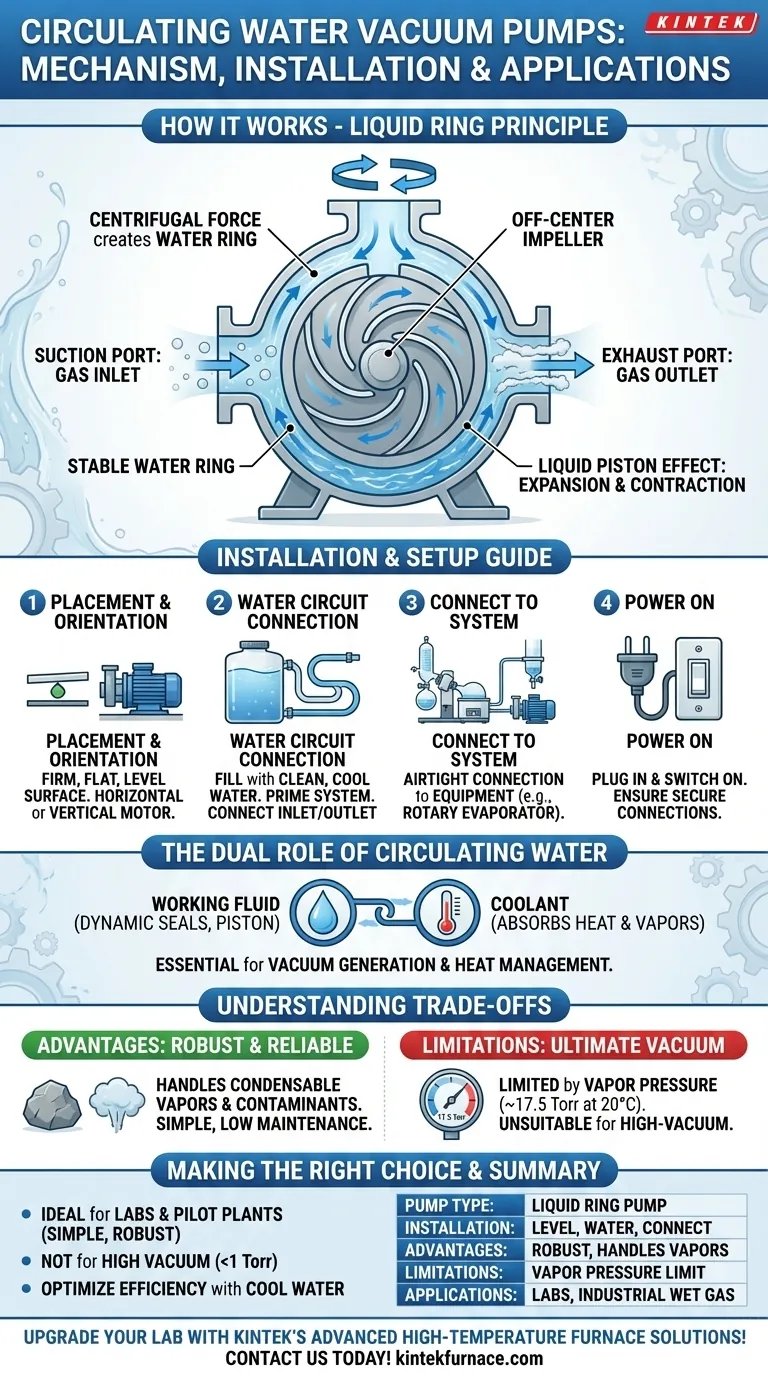

How a Water Ring Vacuum Pump Works

To understand its installation and use, you must first grasp its elegant operating principle. It relies on a few key components working in concert.

The Core Components

The pump consists of a cylindrical casing, a multi-bladed impeller (rotor) mounted eccentrically (off-center) within that casing, and the working fluid—water.

Creating the Water Ring

When the motor spins the impeller, centrifugal force throws the water outwards against the inner wall of the pump casing. This forms a stable, concentric ring of liquid that rotates with the impeller.

The "Liquid Piston" Effect

Because the impeller is mounted eccentrically, the space between the impeller hub and the liquid ring constantly changes. As the blades rotate, the space expands, drawing gas in from the suction port. As rotation continues, that same space contracts, compressing the gas and expelling it through the exhaust port. This repeating cycle of expansion and contraction is what creates the vacuum.

Understanding Installation and Setup

Proper installation is straightforward but critical for ensuring the pump achieves its specified vacuum level and operates reliably.

Physical Placement and Orientation

The pump unit must be placed on a firm, flat, and level surface. While many common laboratory models feature a vertical motor and a compact footprint, larger industrial units are often designed for horizontal installation. The drive motor can typically be positioned on either the left or right side to accommodate the facility layout.

Connecting the Water Circuit

The water tank must be filled with clean, cool water. The level should be high enough to prime the system, often near the overflow nozzle or the inlet/outlet ports. Hoses are then connected to the inlet and outlet ports to enable the circulation that gives the pump its name and its cooling properties.

Connecting to the System

A vacuum-rated hose connects the pump's suction port to the equipment you need to evacuate, such as a rotary evaporator, filtration apparatus, or reaction vessel. Ensure this connection is airtight to prevent leaks that would degrade performance. Once all connections are secure, the unit can be plugged in and switched on.

The Dual Role of the Circulating Water

The "circulating water" in the name is not just a descriptive term; it highlights the two fundamental jobs the water performs.

It Is the Working Fluid

As described above, the water itself forms the dynamic seals between the impeller blades and the casing. It is the "piston" that draws in and compresses the gas, making it the most critical element of the vacuum-generating process.

It Is the Coolant

The process of compressing gas generates heat. The circulating water absorbs this heat, as well as heat from any condensable vapors (like solvents) being pulled into the pump. This makes the pump exceptionally good at handling wet gas streams that would damage other types of vacuum pumps. Some systems connect to an external chiller to keep the water temperature low and vacuum performance high.

Understanding the Trade-offs

Like any technology, the liquid ring pump has a specific set of advantages and limitations that make it suitable for certain tasks.

Limitation: Ultimate Vacuum

A water ring pump's ultimate vacuum is limited by the vapor pressure of the working fluid. For water at 20°C (68°F), this is around 17.5 Torr (23 mbar). You cannot achieve a vacuum deeper than this, making it unsuitable for high-vacuum applications on its own.

Advantage: Robustness

This pump design is mechanically simple and can tolerate process contaminants exceptionally well. It can ingest condensable vapors, small liquid slugs, and even some particulates without damage, which would destroy a more delicate dry scroll or rotary vane pump.

Consideration: Water Quality and Temperature

The performance is directly tied to the water. Using dirty water can lead to mineral buildup and wear. As the water temperature increases, its vapor pressure rises, which reduces the maximum vacuum the pump can achieve. Maintaining cool, clean water is essential for optimal operation.

Making the Right Choice for Your Application

Use these points to determine if this pump technology fits your specific goal.

- If your primary focus is a simple, robust vacuum for a lab or pilot plant: A circulating water vacuum pump is an excellent choice due to its simplicity, low maintenance, and ability to handle chemical vapors.

- If your primary focus is achieving high vacuum (below 1 Torr): You will need a different type of pump, or you can use a water ring pump as a "roughing" pump to back a high-vacuum pump like a turbomolecular or diffusion pump.

- If your primary focus is operational efficiency: Ensure your pump's water is kept as cool as practical, as every degree of temperature rise will slightly decrease its maximum achievable vacuum.

By understanding its simple but effective fluid-based mechanism, you can deploy and maintain this reliable workhorse for consistent performance.

Summary Table:

| Aspect | Details |

|---|---|

| Pump Type | Liquid ring vacuum pump using circulating water as working fluid |

| Installation Steps | Place on level surface, connect water circuit, attach vacuum hose to equipment |

| Key Advantages | Robustness, handles condensable vapors, simple design, low maintenance |

| Limitations | Ultimate vacuum limited by water vapor pressure (~17.5 Torr at 20°C) |

| Ideal Applications | Laboratories, industrial setups with wet gas streams, roughing for high-vacuum systems |

Upgrade your laboratory or industrial setup with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to discuss how we can enhance your efficiency and performance!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the primary purpose of using a high-purity quartz vacuum ampule? Unlock High-Quality WSe2 Crystal Growth

- How has the circulating water vacuum pump been received in practical use? Durable, Cost-Effective for Lab Tasks

- What is the primary function of a high-alumina powder crucible? Ensure Purity in Maraging Steel Pre-treatment

- Why is a graphite thermal baffle necessary for thermal field control? Master Single-Crystal Growth Quality

- What processes is the circulating water multifunctional vacuum pump suitable for? Ideal for Clean, Economical Lab Vacuum Needs

- Why is a high-precision DC power supply necessary for PFS? Control Electric Fields for Perfect Plasma Sintering

- What is the primary role of laboratory furnaces in manufacturing and scientific processes? Unlock Precision Thermal Control

- Why is a vacuum suction system required during the exhaust stage of rice straw-based charcoal carbonization?