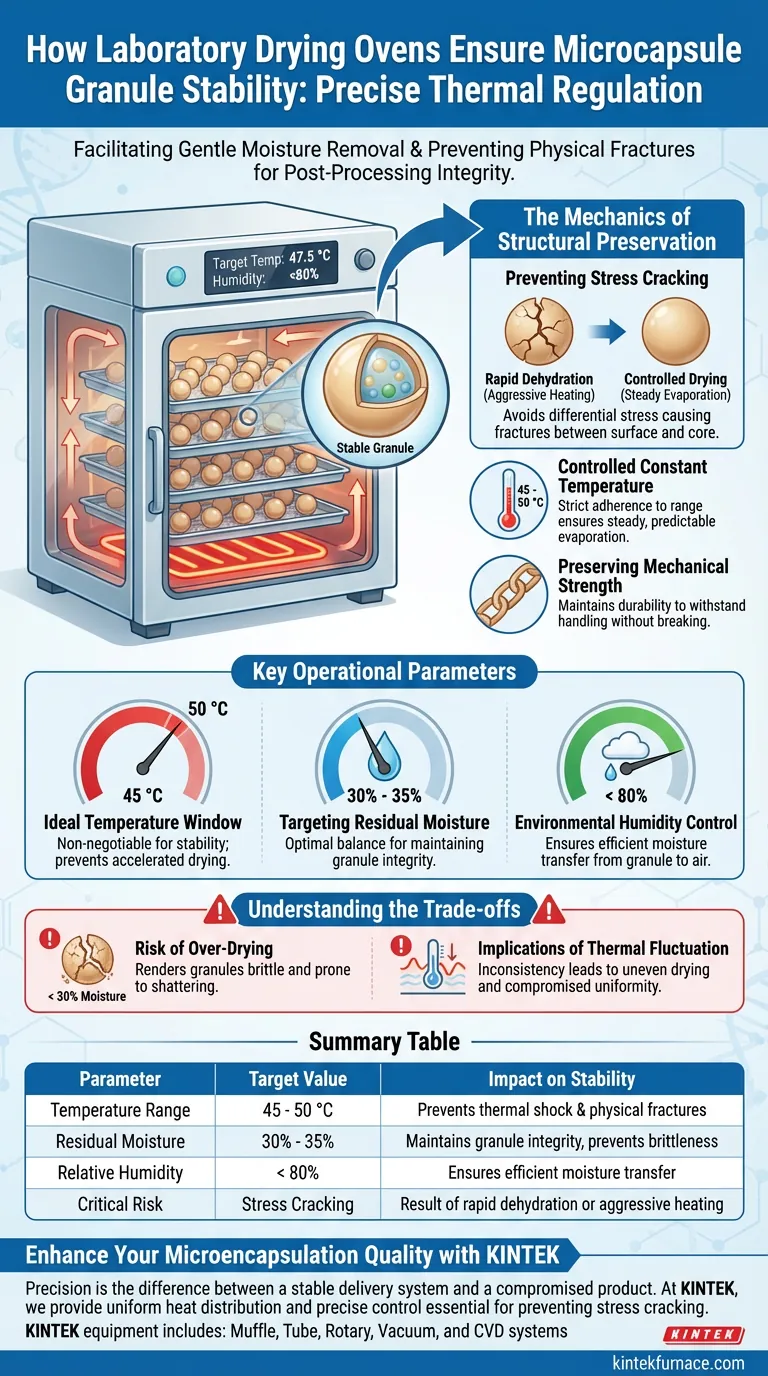

Precise thermal regulation is the mechanism by which a laboratory drying oven ensures the structural stability of microcapsule granules. By maintaining a constant temperature range of 45 to 50 °C, the oven facilitates gentle moisture removal to prevent the physical fractures that compromise the granule's protective shell during post-processing.

The core function of the drying oven is to prevent "stress cracking" caused by rapid dehydration. By stabilizing the thermal environment, the oven preserves the mechanical strength of fertilizer granules and ensures the encapsulated nutrients remain securely contained.

The Mechanics of Structural Preservation

Preventing Stress Cracking

The most critical risk to microcapsules during post-processing is rapid dehydration. If moisture is removed too quickly, the differential stress between the surface and the core of the granule causes the structure to crack.

Controlled Constant Temperature

To mitigate this risk, the laboratory oven provides a constant-temperature environment. Keeping the temperature strictly between 45 and 50 °C ensures that the rate of evaporation is steady and predictable, rather than aggressive.

Preserving Mechanical Strength

This controlled process is directly linked to the durability of the final product. By avoiding thermal shock, the oven maintains the mechanical strength of the fertilizer granules, ensuring they can withstand handling without breaking apart.

Key Operational Parameters

The Ideal Temperature Window

Adherence to the specific range of 45 to 50 °C is non-negotiable for stability. Temperatures exceeding this range risk accelerating the drying process beyond the structural limits of the microcapsule materials.

Targeting Residual Moisture

The goal of the drying phase is not total dehydration, but rather achieving a specific balance. The process targets a residual moisture content of 30 to 35%, which is optimal for maintaining granule integrity.

Environmental Humidity Control

Effective drying requires managing the surrounding atmosphere as well as the heat. The oven environment must maintain a relative humidity below 80% to ensure efficient moisture transfer from the granule to the air.

Understanding the Trade-offs

The Risk of Over-Drying

While removing moisture is necessary, excessive drying can be as damaging as insufficient drying. Deviating below the 30% residual moisture target can render the granules brittle and prone to shattering.

Implications of Thermal Fluctuation

Inconsistency in the heating element can lead to uneven drying rates across a batch. If the oven fails to maintain the constant temperature band, some granules may suffer from stress cracking while others remain too moist, compromising the uniformity of nutrient release.

Making the Right Choice for Your Goal

To ensure the success of your microencapsulation process, you must align your drying parameters with your specific quality metrics.

- If your primary focus is Physical Durability: strictly maintain the temperature between 45 and 50 °C to prevent the stress fractures that lower mechanical strength.

- If your primary focus is Nutrient Retention: monitor the residual moisture content closely to ensure it settles between 30 and 35%, ensuring the core remains encapsulated.

Controlled, gentle drying is the only way to transform a fragile wet granule into a stable, effective delivery system.

Summary Table:

| Parameter | Target Value | Impact on Stability |

|---|---|---|

| Temperature Range | 45 - 50 °C | Prevents thermal shock & physical fractures |

| Residual Moisture | 30% - 35% | Maintains granule integrity and prevents brittleness |

| Relative Humidity | < 80% | Ensures efficient moisture transfer and steady drying |

| Critical Risk | Stress Cracking | Result of rapid dehydration or aggressive heating |

Enhance Your Microencapsulation Quality with KINTEK

Precision is the difference between a stable delivery system and a compromised product. At KINTEK, we understand that delicate materials require specialized thermal solutions. Our advanced laboratory ovens provide the uniform heat distribution and precise temperature control essential for preventing stress cracking in microcapsule granules.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of lab high-temp equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard laboratory drying or customizable systems for unique research requirements, our technology ensures your materials achieve peak mechanical strength and nutrient retention.

Ready to optimize your drying process? Contact us today to discuss your project and see how our customizable furnace solutions can support your scientific innovation.

Visual Guide

References

- Alibek Mutushev, Dauren Mukhanov. Development and application of microcapsules based on rice husk and metallurgical sludge to improve soil fertility. DOI: 10.1038/s41598-024-73329-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- Why use a fusion furnace and platinum crucibles for XRF analysis of magnesium slag? Ensure Accurate Results

- What is the function of a high-pressure stainless steel autoclave? Master Hydrothermal Synthesis of Nanomaterials

- What is the technical necessity of using a glass boat in a pyrolysis furnace? Precision in Thermal Decomposition

- Are customization options available for alumina ceramic furnace tubes? Tailor Them for Your Lab's Needs

- What type of motor does the circulating water multifunctional vacuum pump use? Discover Its Oil-Free Benefits

- How does the geometric design of a sample basket affect measurement accuracy in thermogravimetric analysis?

- What type of medium is allowed in water circulating vacuum pumps? Ensure Optimal Performance and Longevity

- Why is a vacuum pump system integrated into a plastic pyrolysis setup? Optimize Yield and Energy Efficiency