Yes, customization for alumina ceramic furnace tubes is widely available and often necessary. Suppliers routinely modify dimensions like length and diameter, alter shapes, and add features such as flanges, grooves, or specific holes to ensure the tube perfectly matches the thermal, mechanical, and geometric requirements of your specific application.

The core decision is not whether customization is possible, but rather how to specify the right modifications. A successful custom tube aligns its physical geometry and material properties with the precise thermal, chemical, and mechanical stresses of your unique process.

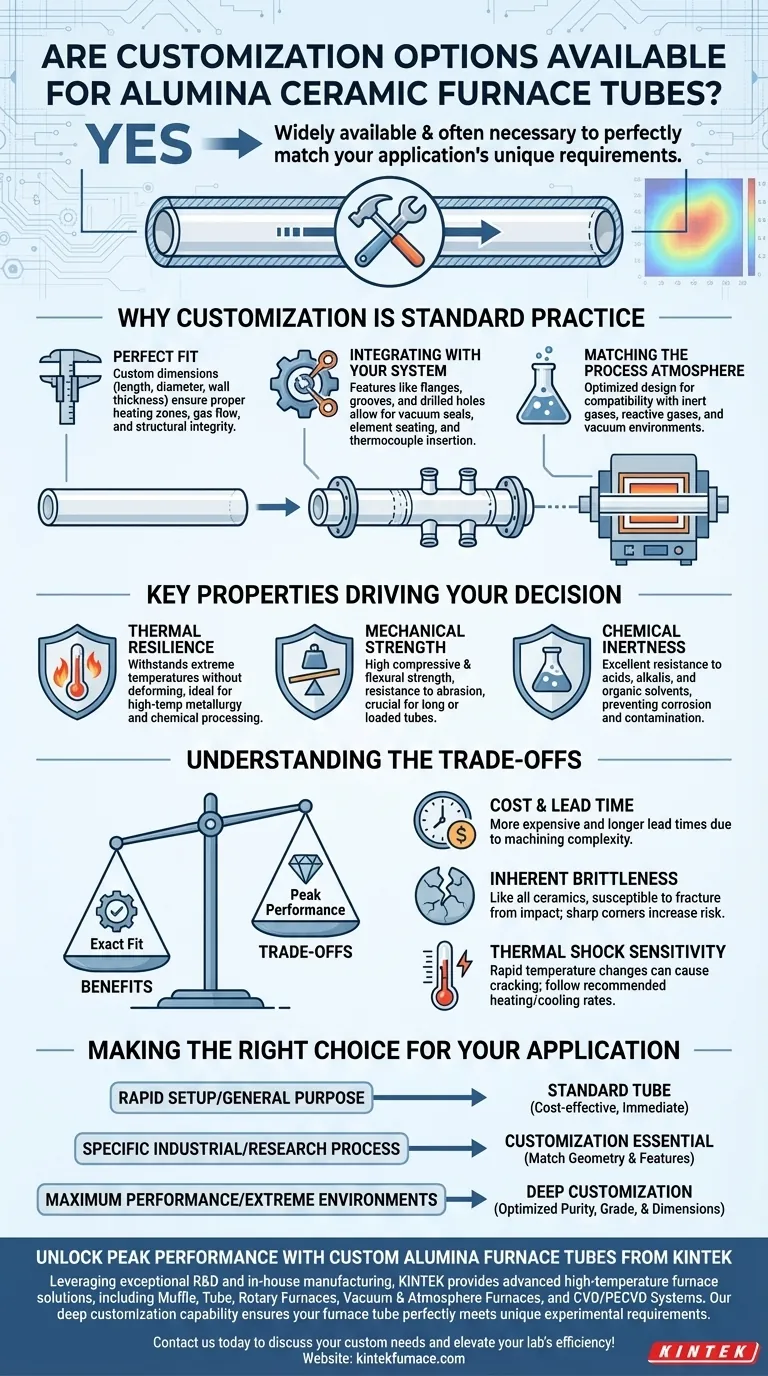

Why Customization is Standard Practice

Off-the-shelf furnace tubes serve many general-purpose applications, but specialized research and industrial processes almost always demand a tailored solution. Customization is about ensuring the tube integrates flawlessly with your system and withstands its unique operating conditions.

The Need for a Perfect Fit

Standard tube sizes may not fit your furnace dimensions, sample holder, or sealing assembly. Customization of length, inner/outer diameter, and wall thickness is the most common and fundamental requirement. This ensures proper heating zones, gas flow, and structural integrity.

Integrating with Your System

A furnace tube is rarely just a simple cylinder. Custom features are often required for it to function as part of a larger system.

- Flanges provide a surface for creating a vacuum-tight seal.

- Grooves can be used for seating O-rings or positioning heating elements.

- Drilled holes allow for the insertion of thermocouples, gas inlets/outlets, or sample manipulators.

Matching the Process Atmosphere

Alumina is compatible with a wide range of atmospheres, including inert gases, reactive gases, and vacuum. Customization ensures the tube's design, particularly any seals or ports, is optimized to maintain the integrity of your specific process environment.

Key Properties Driving Your Decision

When specifying a custom tube, you are making choices based on alumina's inherent material properties. Understanding these properties is critical to designing a tube that performs reliably.

Thermal Resilience

Alumina's primary advantage is its ability to withstand extreme temperatures without deforming or degrading. This makes it ideal for high-temperature metallurgy, semiconductor manufacturing, and chemical processing. The purity of the alumina can influence its maximum service temperature.

Mechanical Strength

A furnace tube must resist mechanical stress. Key properties include:

- Compressive Strength: Resistance to crushing forces.

- Flexural Strength: Resistance to bending, critical for long, horizontally mounted tubes.

- Hardness: Resistance to surface scratching and abrasion from samples or fixtures. Customizing wall thickness is a direct way to increase mechanical strength.

Chemical Inertness

Alumina ceramic offers excellent resistance to most acids, alkalis, and organic solvents, even at high temperatures. However, "excellent" is not universal. You must verify its compatibility with the specific chemicals used in your process to prevent corrosion and contamination.

Understanding the Trade-offs

While customization offers significant benefits, it's crucial to be aware of the associated limitations and trade-offs. An informed decision requires acknowledging these factors.

Cost and Lead Time

Customization is inherently more expensive and requires longer lead times than purchasing a standard, in-stock tube. The complexity of the machining and the quantity ordered will significantly impact both cost and delivery time.

Inherent Brittleness

Like all ceramics, alumina is strong under compression but brittle and susceptible to fracture from impact or mechanical shock. Customization cannot change this fundamental property. Sharp corners in a custom design can create stress concentrations, increasing this risk.

Thermal Shock Sensitivity

Despite its high-temperature stability, alumina can crack if subjected to rapid temperature changes (thermal shock). While design choices can help mitigate this, the material's sensitivity remains a key operational constraint. Always follow recommended heating and cooling rates.

Making the Right Choice for Your Application

Choosing between a standard and custom tube requires balancing your precise technical needs with practical constraints like budget and project timelines.

- If your primary focus is rapid setup or general-purpose heating: A standard-sized tube is the most cost-effective and immediate solution for non-specialized tasks.

- If your primary focus is a specific industrial or research process: Customization is essential to match the tube's geometry and features to your existing equipment and process demands.

- If your primary focus is maximum performance in extreme environments: You must work closely with a supplier to specify not just dimensions, but also the optimal alumina purity and grade for your unique thermal and chemical loads.

Ultimately, investing in the right level of customization ensures your furnace tube is a reliable, high-performance component rather than a potential point of failure.

Summary Table:

| Customization Aspect | Key Details |

|---|---|

| Dimensions | Length, diameter, wall thickness for fit and strength |

| Shapes & Features | Flanges, grooves, holes for system integration |

| Material Properties | Thermal resilience, mechanical strength, chemical inertness |

| Trade-offs | Cost, lead time, brittleness, thermal shock sensitivity |

Unlock Peak Performance with Custom Alumina Furnace Tubes from KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need tailored dimensions, specific features, or optimized material properties, we ensure your furnace tube integrates seamlessly and withstands extreme conditions.

Contact us today to discuss your custom needs and elevate your lab's efficiency and reliability!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents