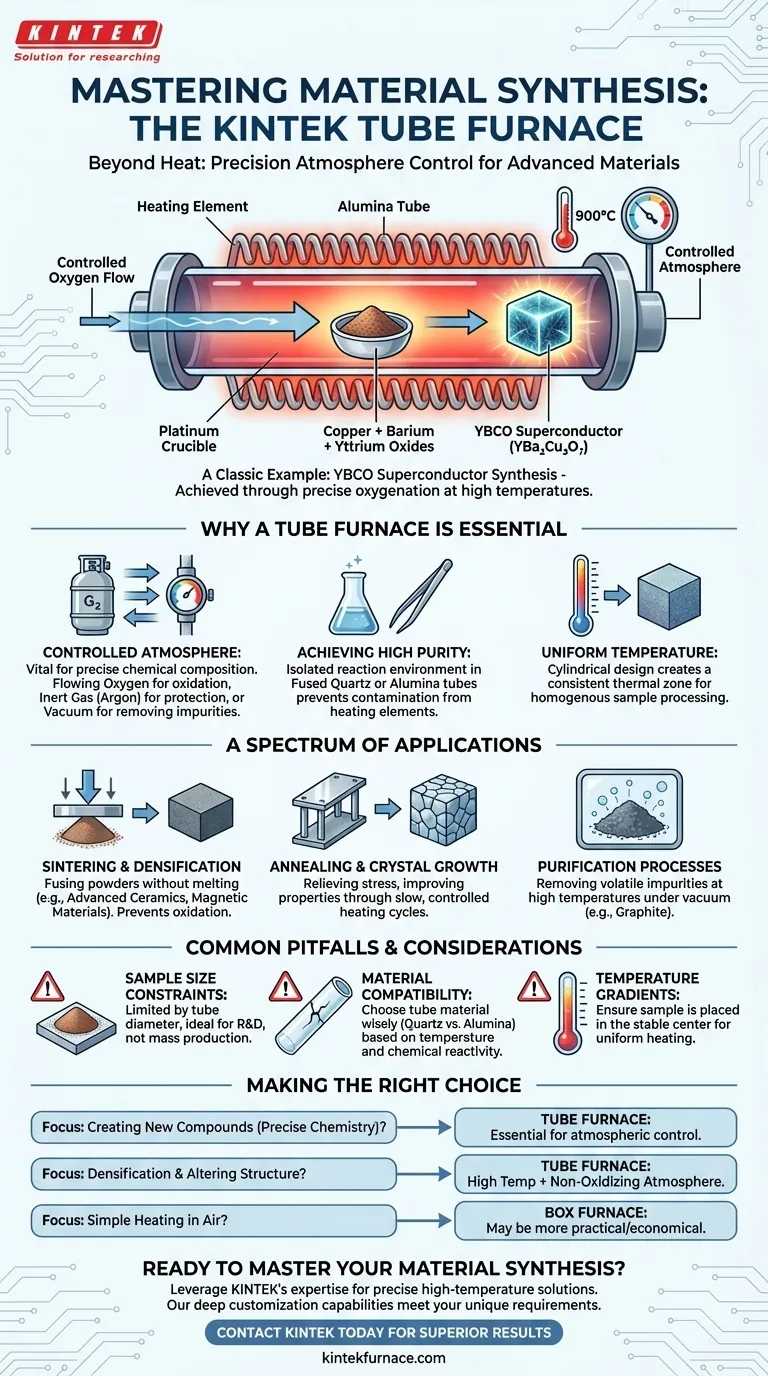

A classic example of a material prepared in a tube furnace is the high-temperature superconductor Yttrium Barium Copper Oxide, or YBa₂Cu₃O₇. This advanced ceramic is synthesized by heating a precise mixture of powdered copper, barium, and yttrium oxides to several hundred degrees within an alumina or platinum container, all while a controlled stream of oxygen flows through the tube.

A tube furnace is not just a high-temperature oven; it is a precision instrument for material synthesis. Its defining feature is the ability to maintain absolute control over the gaseous atmosphere surrounding a sample, which is often more critical than the heat itself.

Why a Tube Furnace is Essential

Synthesizing advanced materials like superconductors is impossible in a standard oven. The unique design of a tube furnace provides a level of control over the reaction environment that is fundamental to achieving the desired material properties.

The Principle of Controlled Atmosphere

The synthesis of YBa₂Cu₃O₇ requires a specific amount of oxygen in its final crystal structure. By heating the components under a continuous flow of pure oxygen, a tube furnace ensures the material becomes properly oxidized.

This same principle allows for immense versatility. Researchers can prevent unwanted oxidation by flowing an inert gas like argon, or create a vacuum to remove all reactive gases, which is essential for processing sensitive metals.

Achieving High Purity

At extreme temperatures, everything becomes more reactive. The sample must be isolated from any potential contaminants, including the heating elements of the furnace itself.

The reaction tube, typically made of highly stable alumina or fused quartz, acts as a pristine, sealed chamber. The sample itself is often placed in a crucible or "boat" made of a non-reactive material like platinum to ensure no impurities are introduced.

Uniform Temperature Profile

The cylindrical geometry of a tube furnace is designed to create a consistent and stable temperature zone in the center of the tube. This uniformity ensures that the entire sample undergoes the same thermal process, leading to a homogenous final product.

A Spectrum of Modern Applications

While YBa₂Cu₃O₇ is a canonical example, the capabilities of tube furnaces extend to a wide range of critical materials and processes used in modern technology.

Sintering and Densification

Sintering is a process where powdered materials are heated to fuse them into a solid, dense object without melting them.

Tube furnaces are ideal for sintering advanced ceramics, magnetic materials, and refractory metal alloys like tungsten-copper. Using a vacuum or inert atmosphere prevents the powders from oxidizing during densification.

Annealing and Crystal Growth

Annealing involves heating a material to alter its microstructure, which can relieve internal stresses, improve ductility, or refine its crystal grain structure. Tube furnaces provide the slow, controlled heating and cooling cycles necessary for this precision work.

Purification Processes

Some materials, like graphite, can be purified by heating them to very high temperatures in a vacuum. The tube furnace's vacuum capability allows volatile impurities to be baked out and pumped away, leaving a purer final product.

Common Pitfalls and Considerations

While powerful, a tube furnace is a specialized tool with inherent limitations that users must understand to ensure successful outcomes.

Constraints on Sample Size

The diameter of the reaction tube inherently limits the size and volume of the material that can be processed. This makes tube furnaces ideal for research and development or small-scale production, but less suitable for mass manufacturing.

Material Compatibility is Crucial

The choice of tube material is critical. Fused quartz is common but can become brittle and devitrify at sustained temperatures above 1100°C. Alumina tubes can withstand much higher temperatures but may not be suitable for certain reactive chemicals.

Temperature Gradient Effects

Although designed for uniformity, a temperature gradient will always exist between the center and the ends of the tube. For processes highly sensitive to temperature variations, positioning the sample precisely in the center of the thermal zone is essential.

Making the Right Choice for Your Goal

The decision to use a tube furnace hinges on whether you need precise atmospheric control in addition to high heat.

- If your primary focus is creating new compounds with precise chemical compositions: The tube furnace's ability to control the reactive gas environment is its most important feature.

- If your primary focus is densifying powdered materials or altering a material's crystal structure: The combination of high temperature and a non-oxidizing atmosphere (vacuum or inert gas) is the key advantage.

- If your primary focus is simply heating a stable material in air: A less complex and often larger box furnace may be a more practical and economical choice.

Ultimately, the tube furnace is an indispensable tool for anyone who needs to master the interplay between high temperatures and controlled atmospheres in materials science.

Summary Table:

| Material/Process | Key Requirement | Tube Furnace Role |

|---|---|---|

| YBCO Superconductor | Precise Oxygenation | Provides controlled oxygen flow for correct crystal structure |

| Sintering Ceramics | Prevent Oxidation | Maintains inert/vacuum atmosphere during densification |

| Annealing Metals | Uniform Heating | Creates stable thermal zone for microstructure refinement |

| Graphite Purification | Remove Impurities | High-temperature vacuum bakes out volatile contaminants |

Ready to Master Your Material Synthesis?

Whether you are developing next-generation superconductors, sintering advanced ceramics, or purifying sensitive materials, the precise control of a KINTEK tube furnace is essential.

Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature solutions. Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

Contact KINTEK today to discuss how our expertise can help you achieve superior results and accelerate your research and development.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide