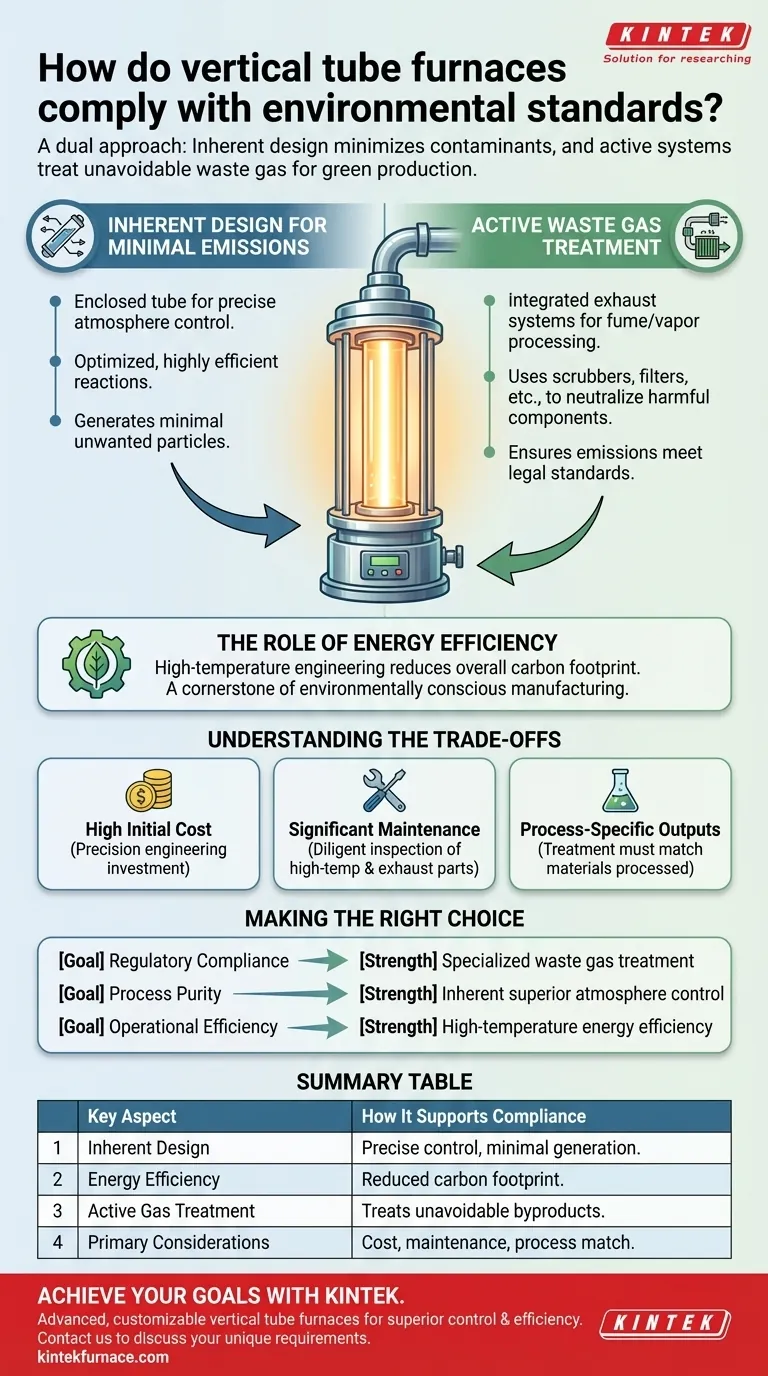

At their core, vertical tube furnaces comply with environmental standards through a dual approach: an inherent design that minimizes the creation of contaminants and the integration of professional treatment systems to handle any waste gas that is generated. This ensures that emissions meet stringent national standards for modern, green industrial production.

The key to compliance is understanding that a vertical tube furnace's environmental performance is not just an add-on. It stems directly from its design for high-temperature precision and atmosphere control, which inherently reduces waste, supplemented by a targeted exhaust treatment system.

The Two Pillars of Environmental Compliance

A vertical tube furnace's ability to meet environmental regulations rests on two complementary principles: preventing the creation of emissions wherever possible and actively treating any byproducts that are unavoidably produced.

Inherent Design for Minimal Emissions

The fundamental design of a vertical tube furnace contributes significantly to its clean operation. The enclosed vertical tube allows for excellent atmosphere control.

This precision means processes can be optimized to be highly efficient, leading to more complete reactions and generating minimal unwanted particles. A well-controlled process is a cleaner process.

The Role of Energy Efficiency

These furnaces are engineered for high-temperature applications, and a major part of that engineering is energy efficiency.

By using energy more effectively to reach and maintain extreme temperatures, they reduce the overall carbon footprint of the operation. This efficiency is a cornerstone of environmentally conscious manufacturing.

Active Waste Gas Treatment

For processes that inherently generate fumes, vapors, or other gaseous byproducts, the furnace must be equipped with a professional exhaust system.

This system actively treats the waste gas before it is vented. Depending on the specific materials being processed, this can involve scrubbers, filters, or afterburners to neutralize harmful components and ensure the final emissions are safely within legal limits.

Understanding the Trade-offs

While effective, achieving this level of performance and compliance involves important considerations. Acknowledging these trade-offs is crucial for making an informed decision.

High Initial Cost

The advanced materials and precision engineering required for high-temperature efficiency and containment come at a price. These furnaces represent a significant capital investment compared to less sophisticated equipment.

Significant Maintenance Requirements

To maintain peak performance and ensure compliance over time, these systems require diligent and often specialized maintenance. The components that handle extreme temperatures and treat exhaust gases must be regularly inspected and serviced.

Process-Specific Outputs

The furnace itself is a clean platform, but the environmental output is ultimately determined by the materials being processed inside it. A system designed to handle metal alloys may not be equipped to treat the off-gassing from certain polymers. The waste gas treatment must be matched to the application.

Making the Right Choice for Your Application

Selecting the appropriate vertical tube furnace configuration requires aligning its capabilities with your primary operational goals.

- If your primary focus is regulatory compliance: Ensure the furnace's waste gas treatment system is explicitly designed to handle the specific chemical byproducts of your materials.

- If your primary focus is process purity: Leverage the design's inherent ability for superior atmosphere control, which minimizes particle generation and supports both a clean product and clean emissions.

- If your primary focus is operational efficiency: The furnace's energy efficiency is a key strength that reduces long-term running costs and contributes directly to your organization's environmental goals.

By aligning the furnace's inherent design and its treatment systems with your specific process, you can achieve an operation that is both highly effective and environmentally responsible.

Summary Table:

| Key Aspect | How It Supports Compliance |

|---|---|

| Inherent Design | Enclosed vertical tube enables precise atmosphere control, leading to efficient reactions and minimal particle generation. |

| Energy Efficiency | Optimized high-temperature engineering reduces the overall carbon footprint of the operation. |

| Active Gas Treatment | Integrated exhaust systems (scrubbers, filters) treat unavoidable byproducts to meet emission standards. |

| Primary Considerations | High initial investment, specialized maintenance, and process-specific treatment requirements. |

Achieve Your Environmental and Performance Goals with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our vertical tube furnaces are engineered for superior atmosphere control and energy efficiency, helping you minimize emissions from the start. We complement this with robust customization to ensure the integrated exhaust system is perfectly matched to your specific process and materials, guaranteeing compliance.

Ready to build a cleaner, more efficient operation? Contact our experts today to discuss how our vertical tube furnaces and deep customization capabilities can meet your unique requirements.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide